A processing technology of fire truck telescopic water pipe

A technology of telescopic water pipe and processing technology, which is applied in the field of processing technology of fire truck telescopic water pipe, can solve problems such as inconvenient use, self-heavy telescopic water pipe, reduce self-weight of telescopic water pipe, etc., and achieve high matching precision, high hardness and wear resistance, The effect of reducing the risk of difficulty in drawing or leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

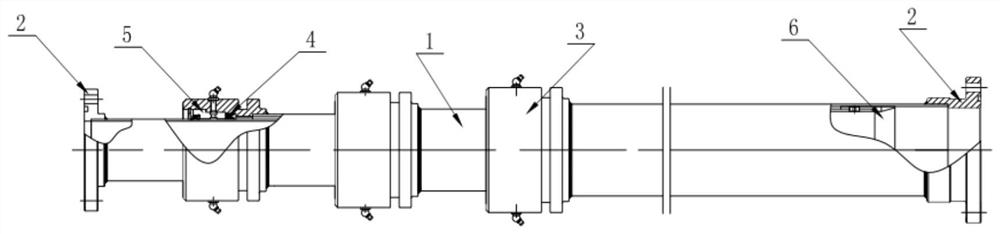

[0028] As shown in the figure, the fire truck telescopic water pipe of the present invention includes a plurality of overlapping water pipes 1 of different diameters, a plurality of flanges 2, a plurality of joint sleeves 3, a plurality of sealing assemblies, a plurality of sliding assemblies and a plurality of The guide assembly, the sealing assembly may include a sealing ring 4 , the guide assembly may include a guide ring 5 , and the sliding assembly may include a sliding sleeve 6 .

[0029] The processing technology of fire truck telescopic water pipe among the present invention, comprises the following steps:

[0030] (1) Cutting the water pipes of different diameters in the telescopic water pipe according to the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com