Improved cutting, drilling and grinding mechanism

A technology of drilling, grinding and belt pulleys, which is applied in the direction of grinding machines, grinding drive devices, grinding machine parts, etc., can solve the problems of high cost, low degree of automation of small equipment, and inability to quickly adjust the position of the working platform, etc., to achieve convenient operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

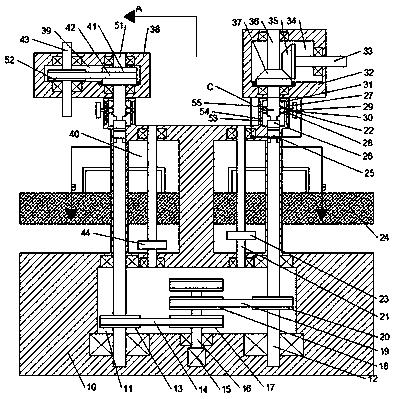

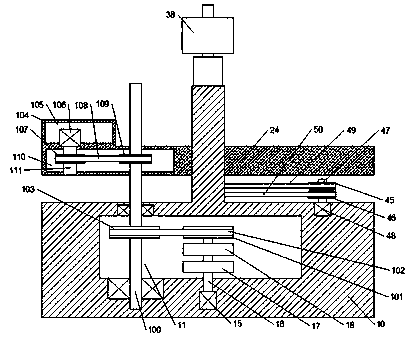

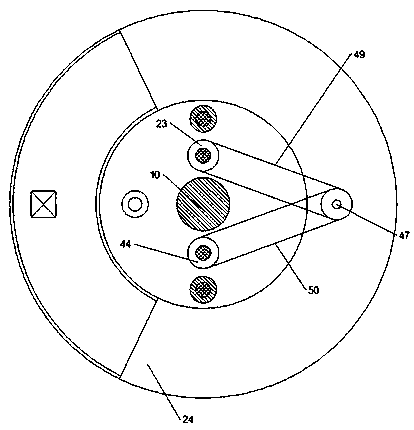

[0013] Combine below Figure 1-4 The present invention will be described in detail.

[0014] refer to Figure 1-4 , an improved cutting, drilling and grinding mechanism according to an embodiment of the present invention, including a cutting body 10, a transmission cavity 11 is provided inside the cutting body 10, and the bottom wall of the transmission cavity 11 is symmetrically rotated and extended upwards Through the transmission shaft 12 on the top end surface of the cutting main body 10, the cross groove interface 25 is fixedly installed on the top end surface of the left and right transmission shafts 12, and the first pulley 13 is fixedly installed on the left shaft of the left and right transmission shafts 12. A first motor 15 is fixedly installed on the bottom end surface of the cutting main body 10, and a power shaft 16 is fixedly installed on the top end surface of the upward output shaft of the first motor 15, and a second pulley 17 is fixedly installed on the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com