Steel wire rust removal device applied to machining

A kind of mechanical processing and steel wire technology, which is applied in the direction of metal processing equipment, grinding machine parts, manufacturing tools, etc., can solve the problems of non-oxidized iron scale treatment, increased workload, etc., achieve good rust removal effect, improve work efficiency, The effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

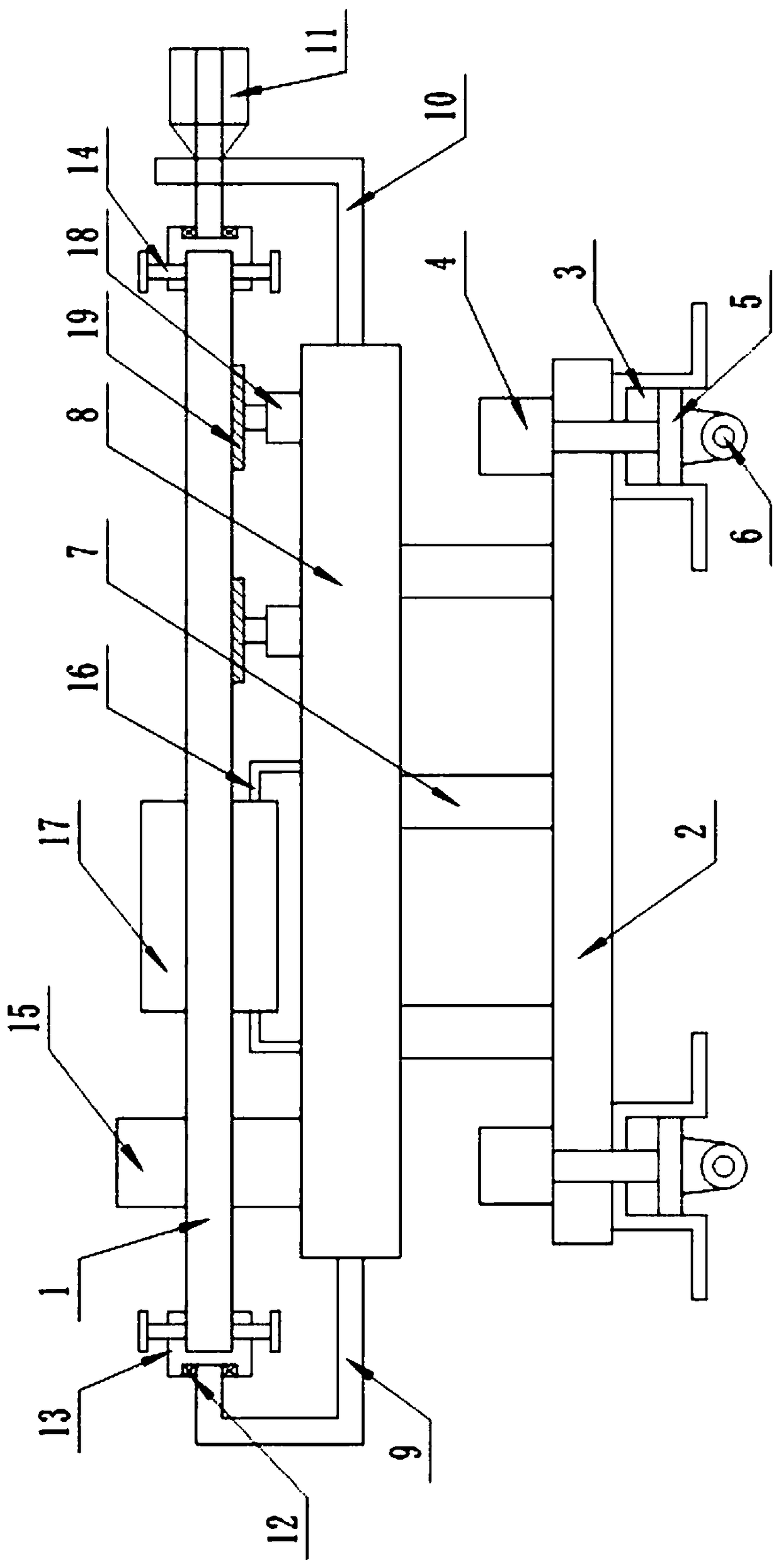

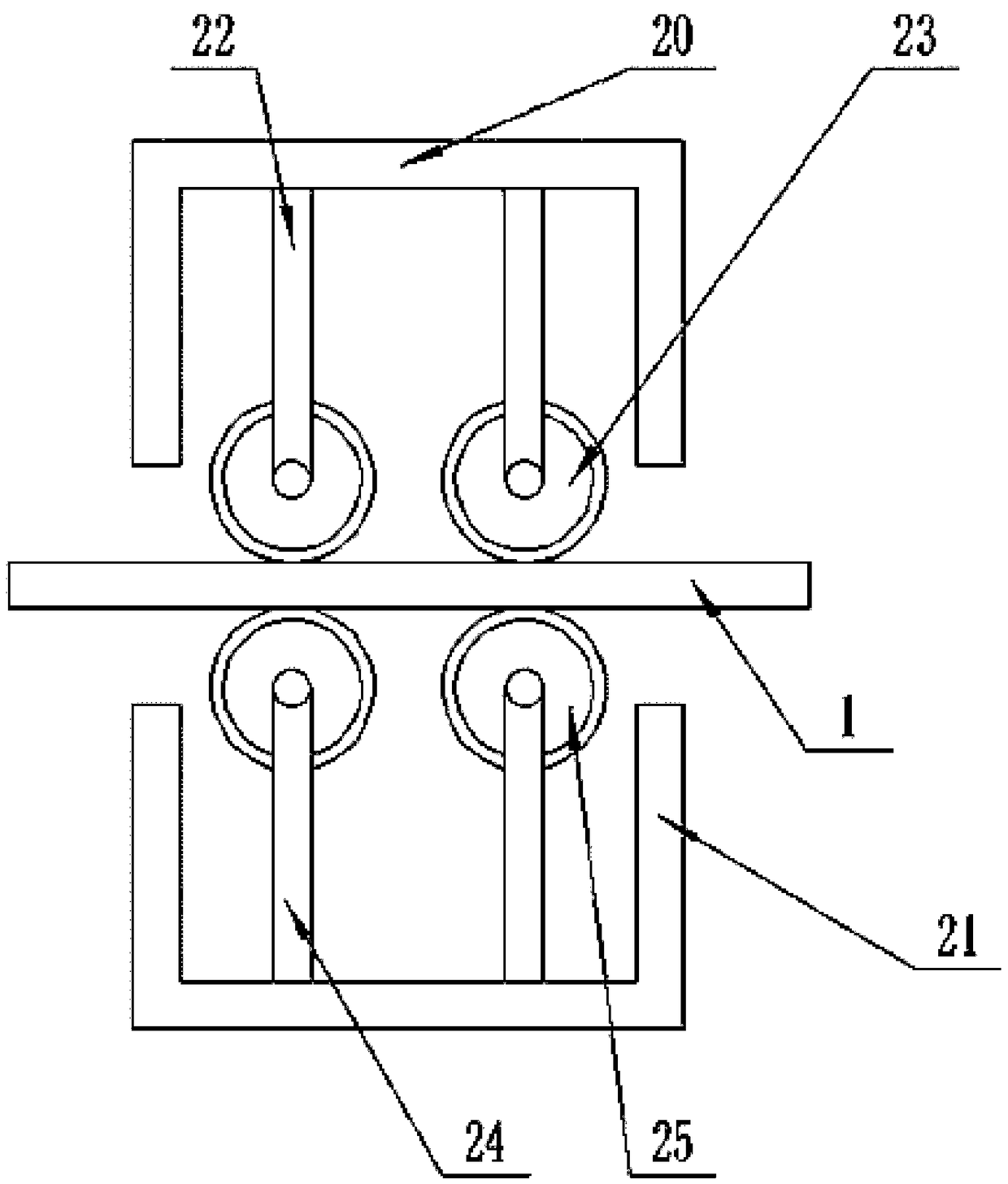

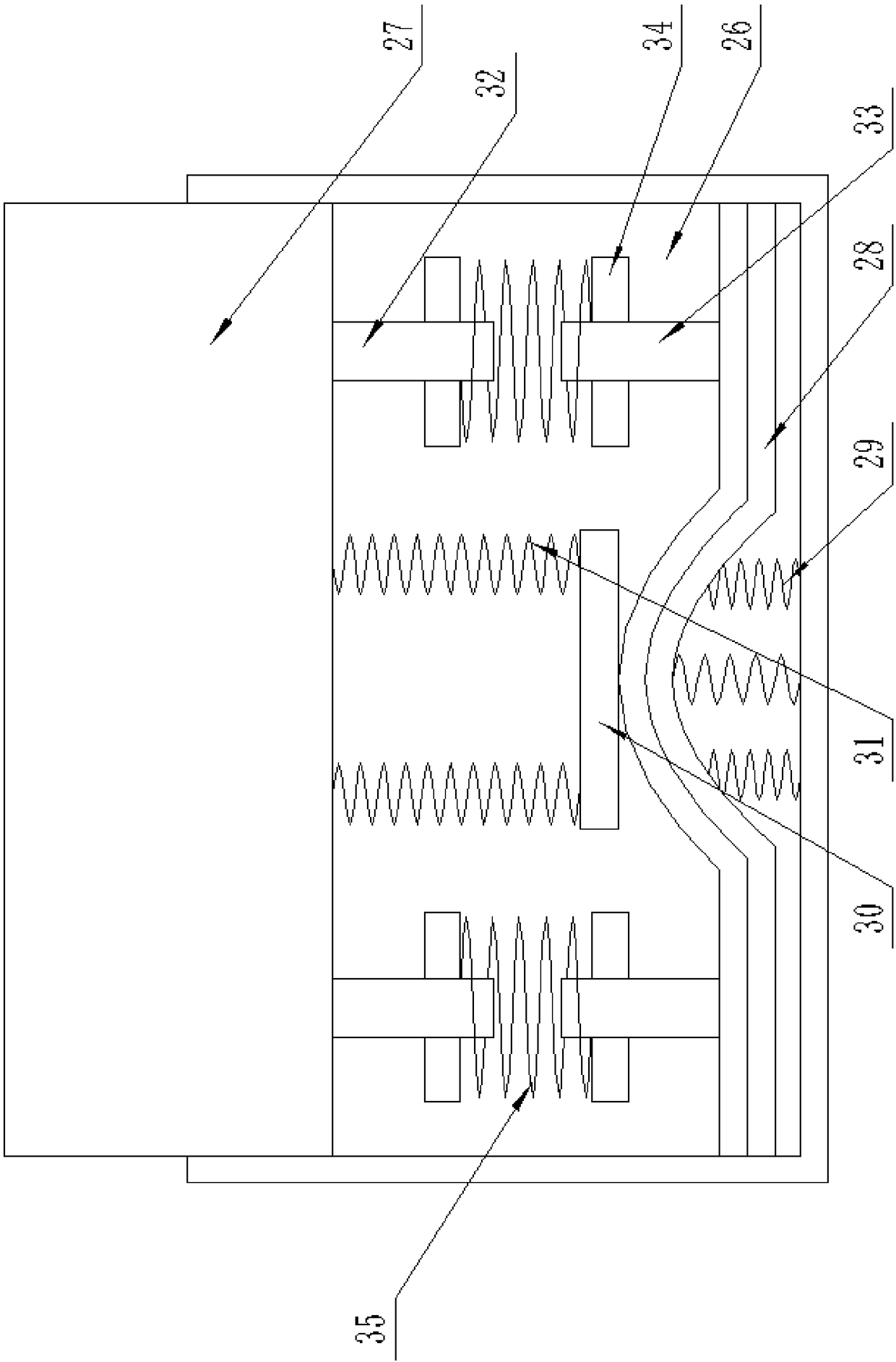

[0041] Such as figure 1As shown, this specific embodiment adopts the following technical solutions: a steel wire derusting device used in mechanical processing, including: steel wire 1, also includes base 2, concave word seat 3, air pressure rod 4, slider 5, pulley 6 , buffer 7, top seat 8, first bracket 9, second bracket 10, drive motor 11, bearing 12, clamping piece 13, locking piece 14, straightening device 15, installation rod 16, grinding roller 17, rotation A motor 18 and a sponge 19; both sides of the lower surface of the base 2 are fixedly connected with a concave character seat 3; a slider 5 is slidably connected in the concave character seat 3; a pulley 6 is connected on the lower surface of the slider 5; Both sides of the upper surface of the base 2 are fixedly connected with an air pressure rod 4, and the output shaft of the air pressure rod 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com