Foam plastic recycling device

A recovery device and technology of foam plastics, applied in plastic recycling, recycling technology, presses, etc., can solve the problems of foam waste occupying a large space and inconvenient transportation, and achieve convenient transportation, space saving, and reduction of occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

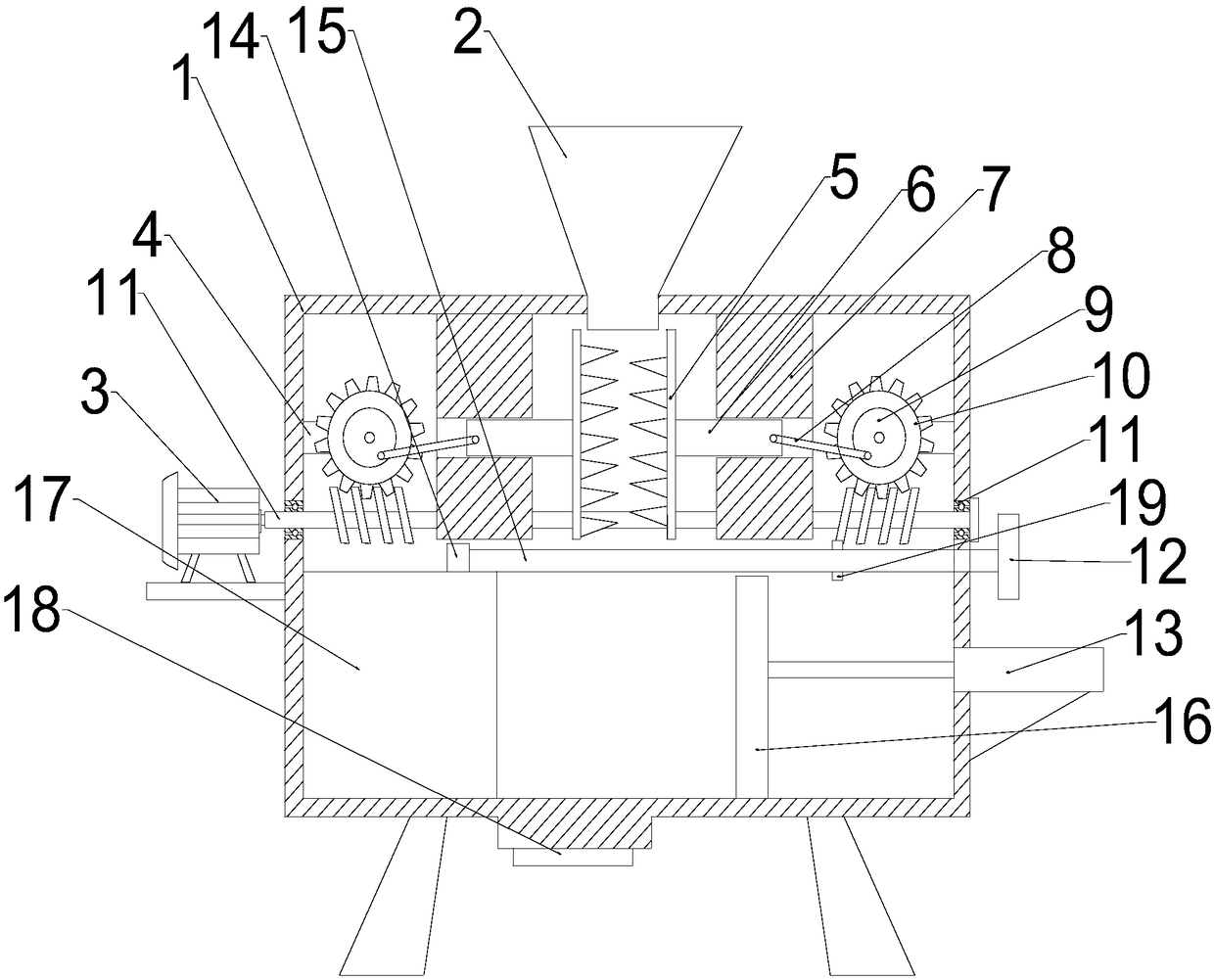

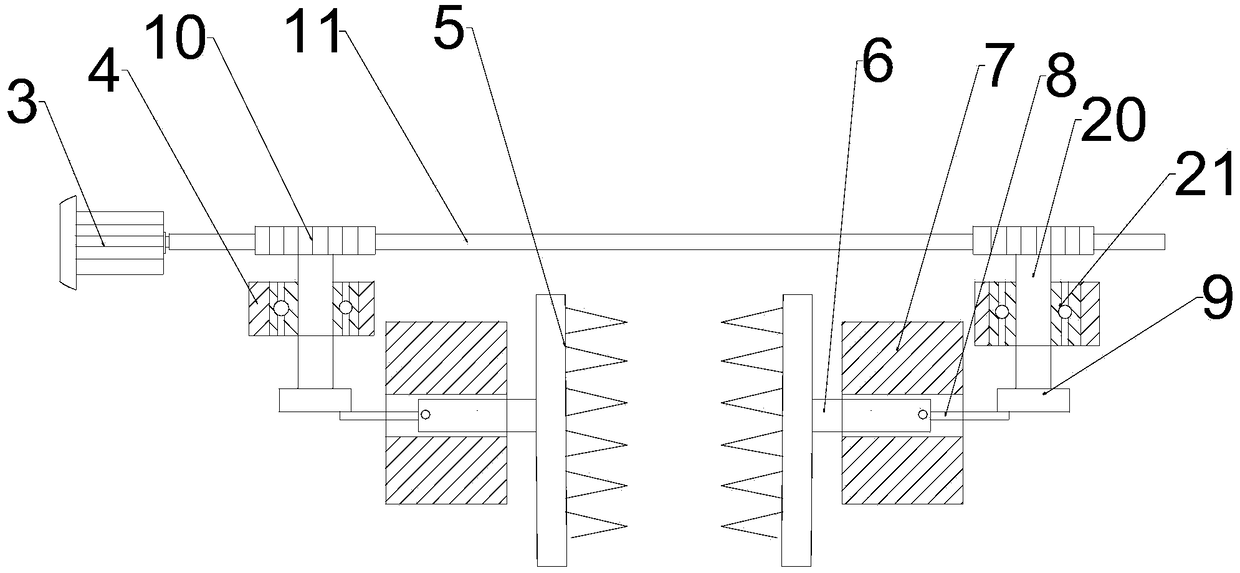

[0027] see Figure 1~2 , a foam recovery device, comprising a box body 1, the top of the box body 1 is fixedly connected with a feed cylinder 2, the top inside of the box body 1 is fixed with a symmetrically placed limiting plate 7 on both sides, and the two sides of the box body 1 are fixed with The fixed plate 4 placed symmetrically, the fixed plate 4 is equipped with a rotatable rotating shaft 20, a gear 10 is fixed on one end of the rotating shaft 20, a rotating wheel 9 is fixed on the other end of the rotating shaft 20, a motor 3 is fixedly installed on the left outer wall of the box body 1, and a motor 3 The output shaft is fixedly connected to one end of the worm 11, and the worm 11 is rotatably connected to both sides of the casing 1. The shaft of the worm 11 is provided with two opposite worm teeth matched with the gear 10 and symmetrical along the center of the casing 1. The gear 10 is meshed with the worm gear, the rotating wheel 9 is hinged with one end of the ecce...

Embodiment 2

[0030] see Figure 1~2 , a foam recovery device, comprising a box body 1, the top of the box body 1 is fixedly connected with a feed cylinder 2, the top inside of the box body 1 is fixed with a symmetrically placed limiting plate 7 on both sides, and the two sides of the box body 1 are fixed with The fixed plate 4 placed symmetrically, the fixed plate 4 is equipped with a rotatable rotating shaft 20, a gear 10 is fixed on one end of the rotating shaft 20, a rotating wheel 9 is fixed on the other end of the rotating shaft 20, a motor 3 is fixedly installed on the left outer wall of the box body 1, and a motor 3 The output shaft is fixedly connected to one end of the worm 11, and the worm 11 is rotatably connected to both sides of the casing 1. The shaft of the worm 11 is provided with two opposite worm teeth matched with the gear 10 and symmetrical along the center of the casing 1. The gear 10 is meshed with the worm gear, the rotating wheel 9 is hinged with one end of the ecce...

Embodiment 3

[0034] see Figure 1~2, a foam recovery device, comprising a box body 1, the top of the box body 1 is fixedly connected with a feed cylinder 2, the top inside of the box body 1 is fixed with a symmetrically placed limiting plate 7 on both sides, and the two sides of the box body 1 are fixed with The fixed plate 4 placed symmetrically, the fixed plate 4 is equipped with a rotatable rotating shaft 20, a gear 10 is fixed on one end of the rotating shaft 20, a rotating wheel 9 is fixed on the other end of the rotating shaft 20, a motor 3 is fixedly installed on the left outer wall of the box body 1, and a motor 3 The output shaft is fixedly connected to one end of the worm 11, and the worm 11 is rotatably connected to both sides of the casing 1. The shaft of the worm 11 is provided with two opposite worm teeth matched with the gear 10 and symmetrical along the center of the casing 1. The gear 10 is meshed with the worm gear, the rotating wheel 9 is hinged with one end of the eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com