Plastic mould with slide block arranged in slide block

A technology of plastic molds and sliders, applied in the field of plastic molds, to achieve the effects of low manufacturing costs, low application costs, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

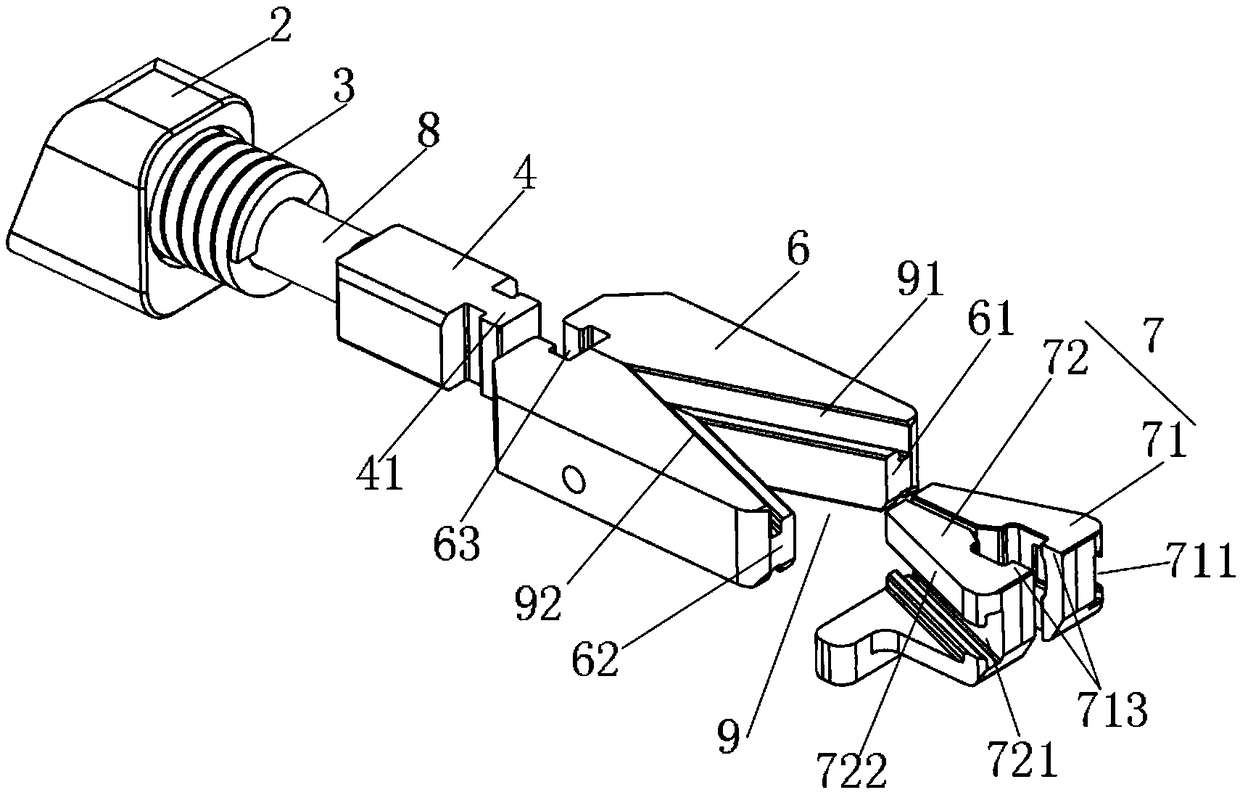

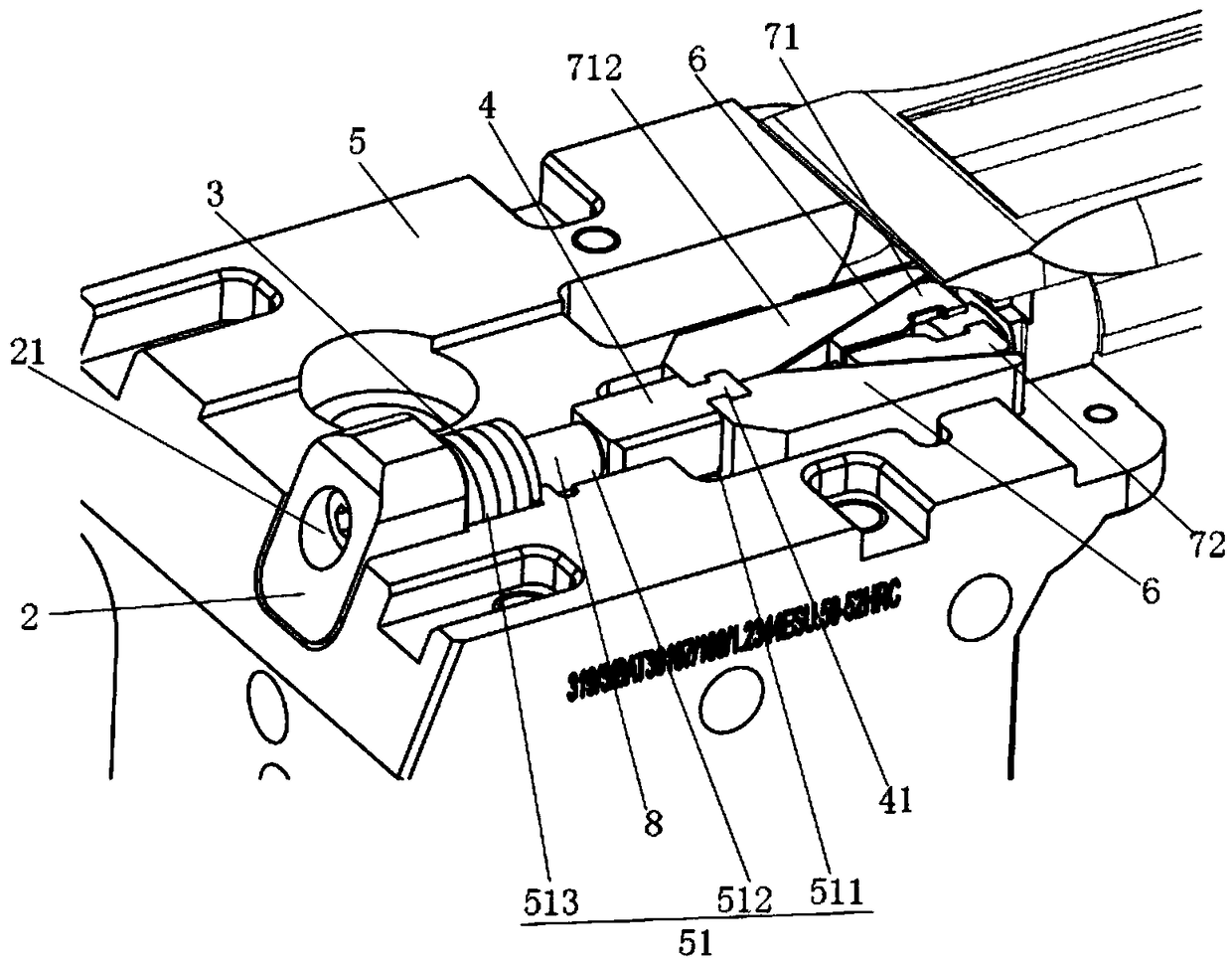

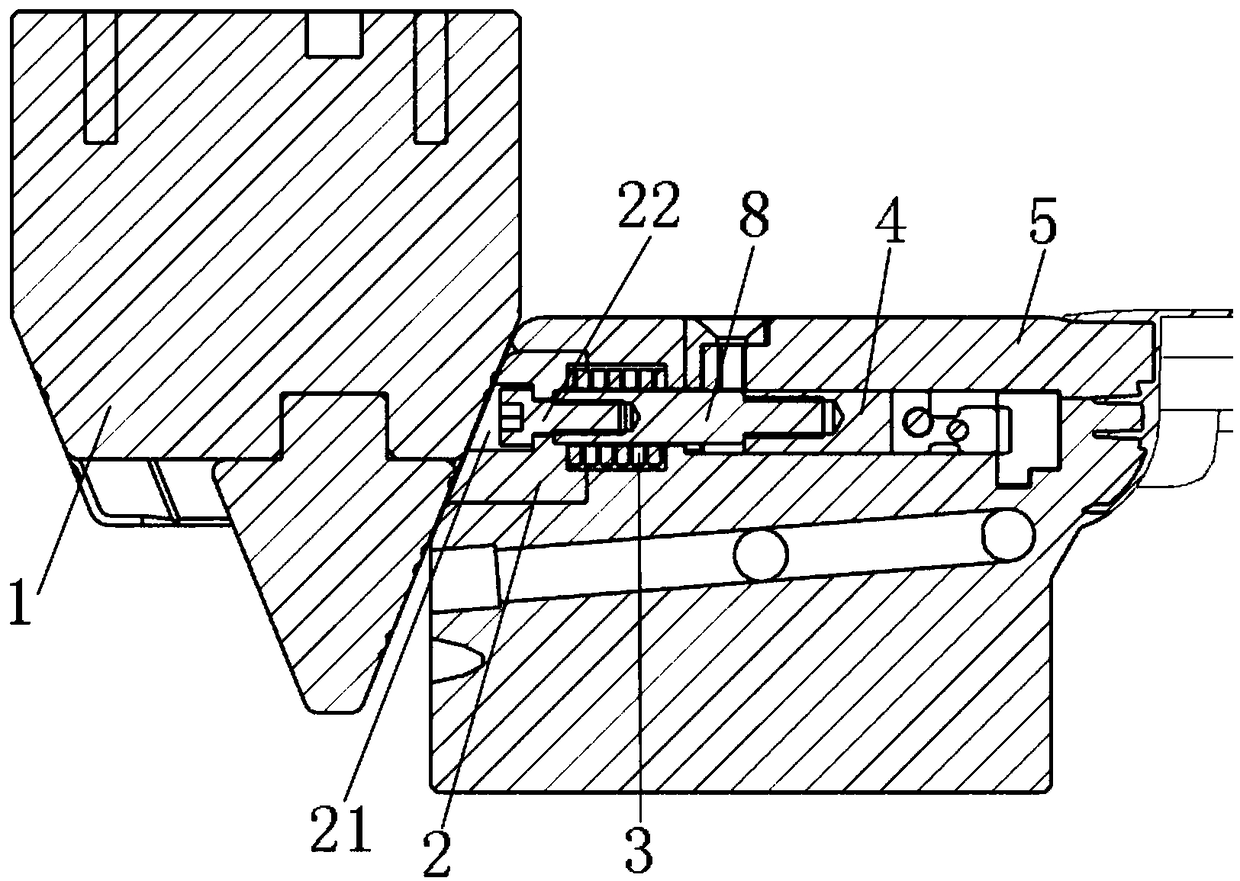

[0029] like Figure 1-3The plastic mold with the slider in the slider shown includes the outer shovel 1, the pressure block 2, the spring 3, the connecting block 4, the slider body 5, the inner shovel 6, the lateral moving slider 7 and the connecting rod 8 , the outer shovel 1 is attached to the end surface of the slider body 5, the pressure block 2, the spring 3, the connecting block 4 and the inner shovel 6 are all arranged in the slider body 5, and the pressure block 2 is far away from the outer One end of the shovel 1 is connected to the spring 3, one end of the connecting rod 8 is arranged on the pressing block 2, and the other end of the connecting rod 8 is connected to the connecting block 4, and the spring 3 is sleeved on the outer wall of the connecting rod 8 , the connecting block 4 is connected with the internal shovel 6, and the laterally moving slider 7 is arranged on the internal shovel 6; wherein, the laterally moving slider 7 includes a first laterally moving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com