Injection molding production line and injection molding process of ABS watch shell

A production line and casing technology, which is applied in the injection molding production line and injection molding process field of ABS watch casing, can solve the problems of low annealing efficiency of annealing device, high production efficiency of injection molding machine, and inability to adapt to the direction of injection molding machine, etc., and achieve water bath annealing Uniformity, high shell quality and efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

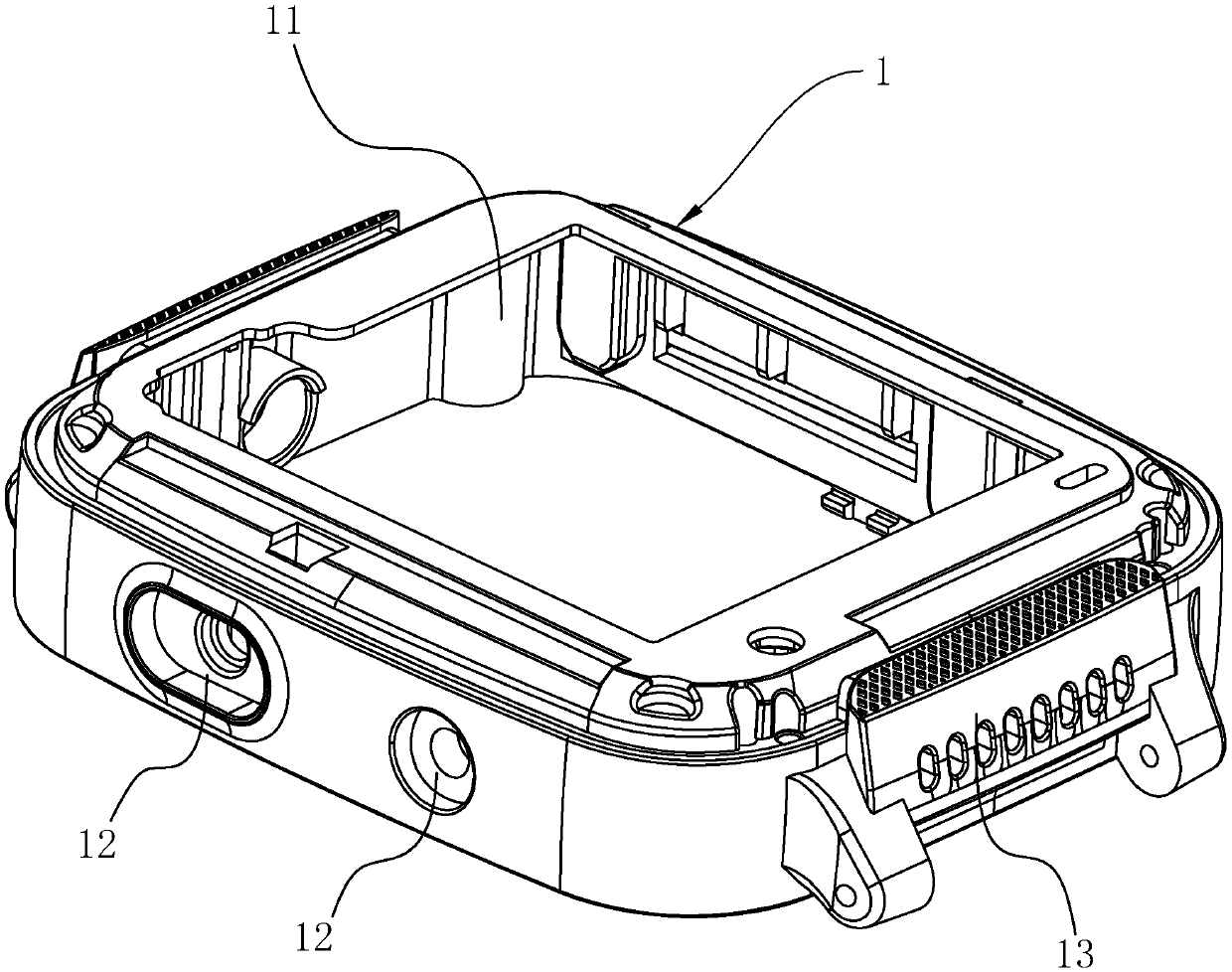

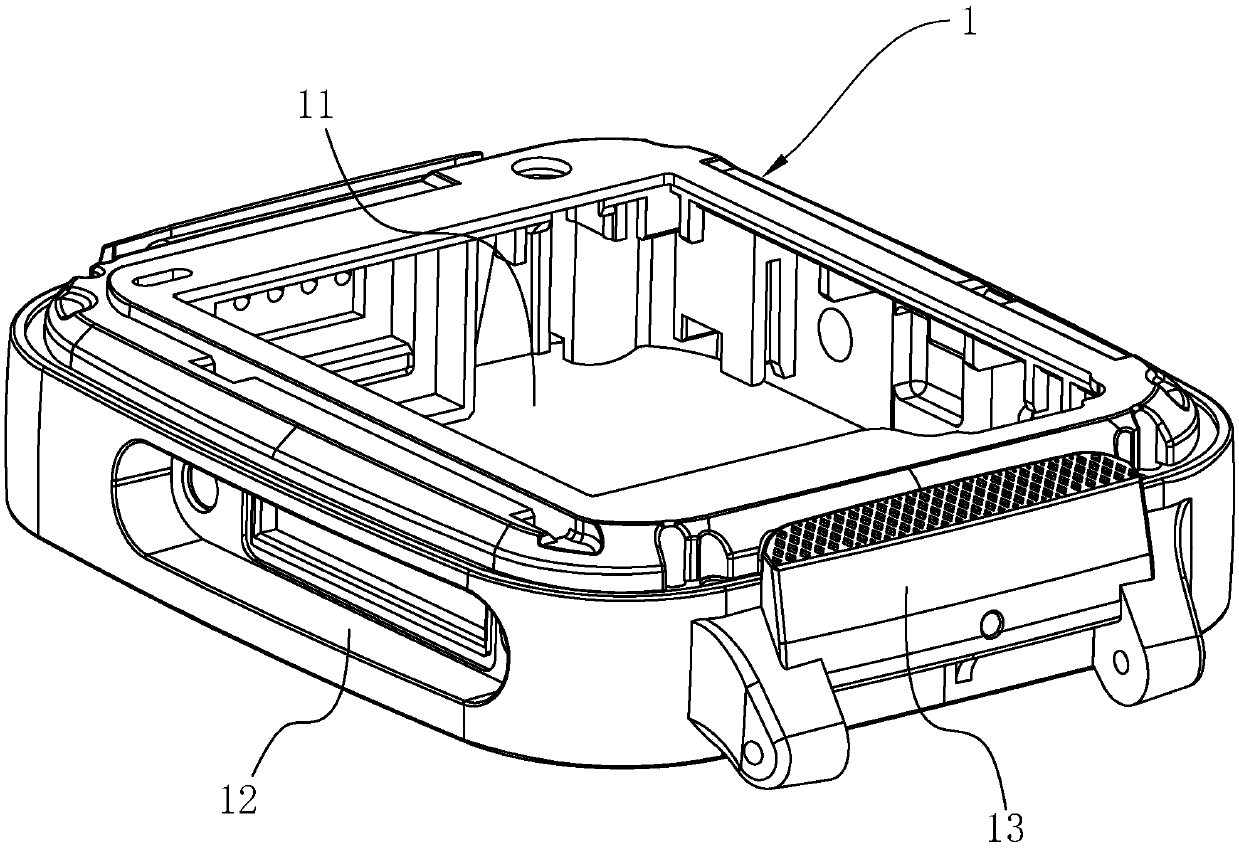

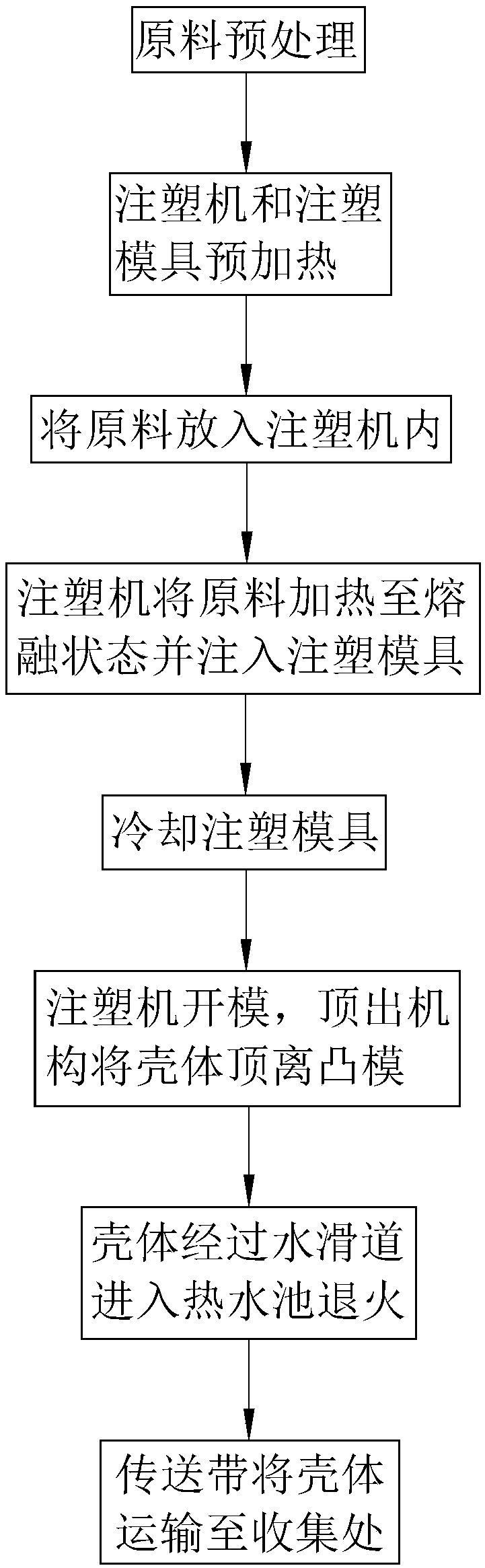

[0063] Embodiment one: a kind of injection molding process of ABS watch case, as image 3 As shown, the ABS raw material is first pretreated, and the raw material is put into an oven 2 to dry for 2-3 hours, and the temperature of the oven 2 is kept at 70°C. Then preheat the injection molding machine 3 and the injection mold 32, heat the hopper to 150°C-160°C, heat the front of the barrel to 180°C-190°C, heat the die head to 185°C-195°C, and heat the mold to 180°C-200°C (the hopper, feed barrel and die are all prior art, and will not be repeated here). Workers put the dry raw material into the screw barrel of the injection molding machine 3 and heat it to a molten state. The injection molding machine 3 injects the raw material in the molten state into the cavity of the injection mold 32 , and the injection mold 32 shapes the shell 1 . Then the injection mold 32 is cooled, and after cooling, the injection molding machine 3 molds the injection mold 32, and the ejection mechanism...

Embodiment 2

[0065] Embodiment two: a kind of injection molding production line of ABS watch casing, as Figure 4 and Figure 5 As shown, it includes an oven 2, an injection molding machine 3 and an annealing device 4. An injection mold 32 is connected to the frame 31, and a blanking port 311 is provided at the position directly below the injection mold 32 corresponding to the frame 31. The annealing device 4 is arranged on the falling The position directly below the feed port 311. The oven 2 keeps the ABS away for drying treatment. The staff puts the dried ABS raw material into the injection molding machine 3. The injection molding machine 3 heats the ABS raw material to a molten state and injects it into the injection mold 32. The injection mold 32 is placed in the casing 1 After molding, the mold is opened by the injection molding machine 3, and the ejector mechanism in the injection mold 32 pushes the formed shell 1 out of the punch, so that the formed shell 1 falls into the annealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com