Vehicle tire inspection device

An overhaul device and tire technology, which is applied in the fields of overhaul devices and vehicle tire overhaul devices, can solve the problems of difficulty in carcass inspection, affecting the progress of tire overhaul, and unclean cleaning, so as to reduce the rolling distance of inspection tires and shorten the rolling distance of inspection tires. Distance, the effect of overcoming the limitations of the narrow venue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

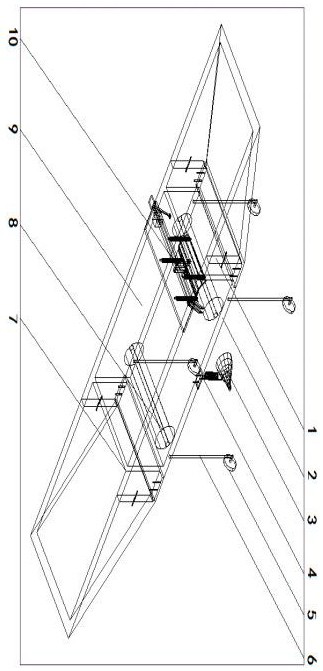

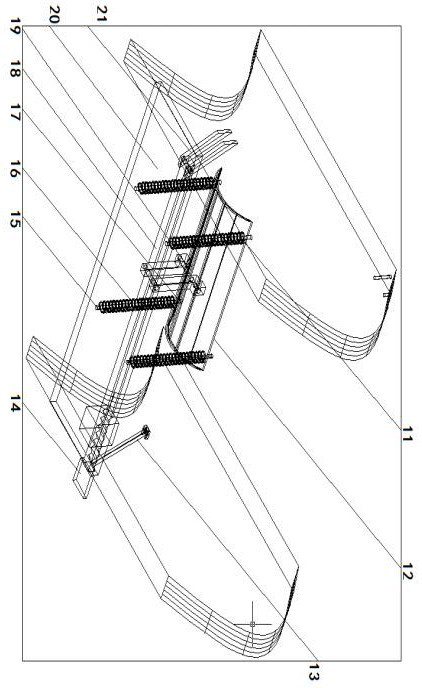

[0017] Embodiment 1: see figure 1 , figure 2 , a vehicle tire inspection device, the inspection device includes a base 1, a ramp 7, a roller assembly 8, a pulley frame 6, a pulley 5, a braking device 10 and a lighting device, the base 1 is equipped with a roller assembly 8, Bearing is installed in described roller assembly 8, and roller assembly 8 is installed on the right and left two ends on the base 1 by the appropriate position of axle, and described pulley frame 6 is respectively installed on the plane on the front and rear sides of base 1, and pulley frame 6 is equipped with respectively Pulley 5, described pulley 5 is installed on the top of pulley frame 6, and described ramp 7 is fixedly connected with two ends of base 1. There are fixed installation holes and hoisting holes at both ends of the base 1 . The brake device 10 includes a brake pad 11, a brake shoe 12, a pedal lock 13, a pedal 14, a spring 15, a positioning guide shaft 16, a positioning guide sleeve 17, ...

Embodiment 2

[0018] Example 2: see figure 1, as an improvement of the present invention, the base 1 is a rectangular base 1 welded by special-shaped channel steel with a thickness of 12 mm, which is to install various accessories and play the role of counterweight. Its appearance is a cuboid with a length of 1200mm, a width of 450mm and a height of 130mm. On appropriate positions on the left and right sides of the base 1, a special roller assembly 8 is housed. A braking device 10 is installed under the roller assembly 8 (two arbitrary ones) on the side of the slope plate 7, and four pulley frames 6 are mounted on the appropriate positions of the special-shaped channel steel on the inner and outer sides of the base 1. Fixed steel plate hole, on the outside special-shaped channel steel of base 1, also illuminating device is housed. On the left or right side of the base 1, according to the actual situation of the site, there is a 6mm-thick textured slope plate 7 connected, and the three sid...

Embodiment 3

[0019] Embodiment 3: see figure 1 , as an improvement of the present invention, the roller assembly 8 is composed of a roller, a roller shaft and a bearing. The roller is made of high-quality mud dragon pillars with a diameter of 80 mm. Bearing holes are processed at both ends of the roller. The inner diameter and the outer diameter of the bearing are used for interference fit, and a through hole with a diameter of 20 mm is processed in the center of the roller to make a roller. Component 8 is installed and used. The roller shaft is made of high-quality round steel processed according to its installation requirements. Described bearing it is installed in mud dragon roller two ends, and its effect is to reduce the friction resistance of roller and axle, makes roller assembly 8 rotate steadily. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com