Article conveying device in an aircraft cabin

A transport device and technology in the cabin, applied in the field of aviation services, can solve the problems of affecting rest of other passengers, heavy labor, frequent services, etc., and achieve the effects of stable structure, high work efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

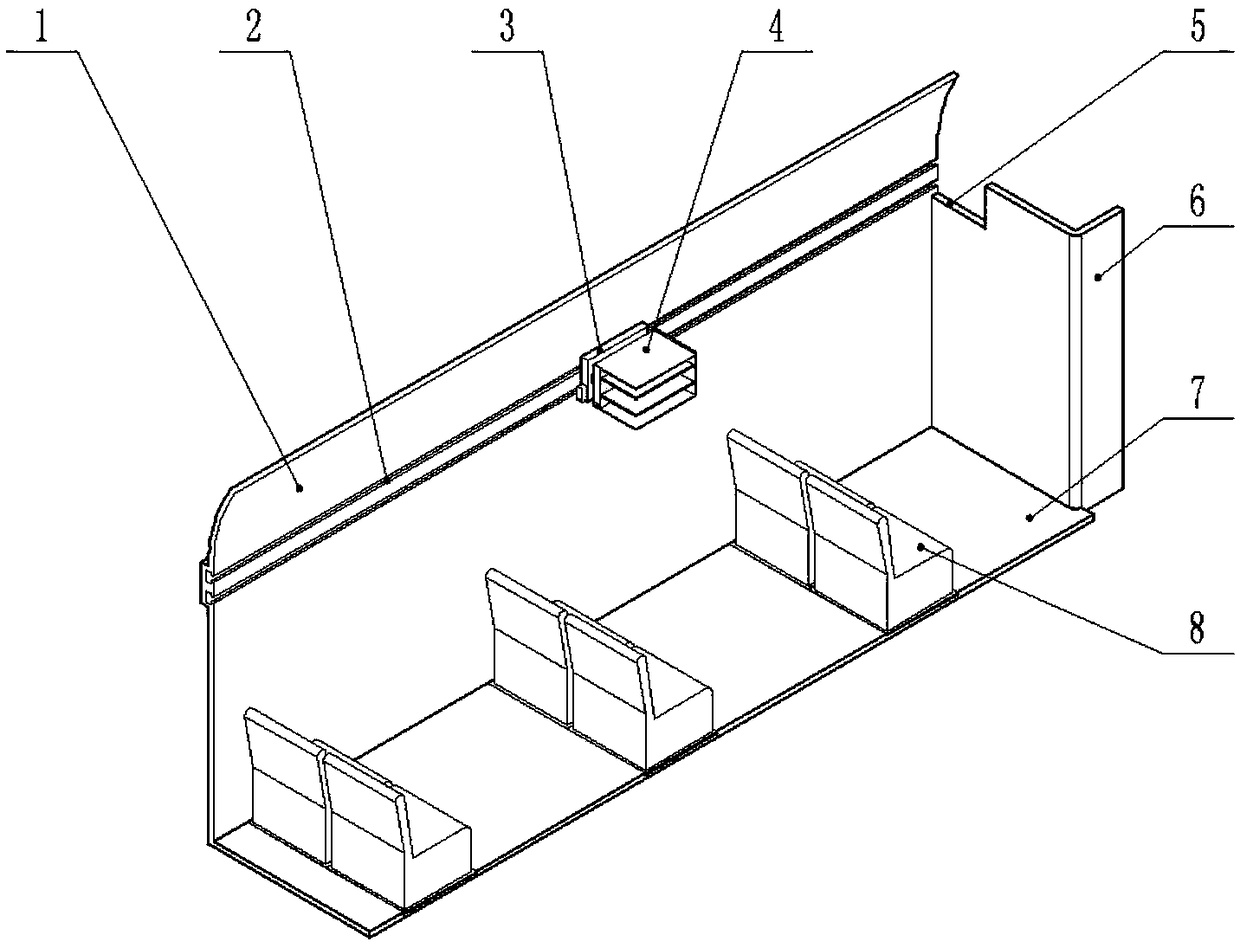

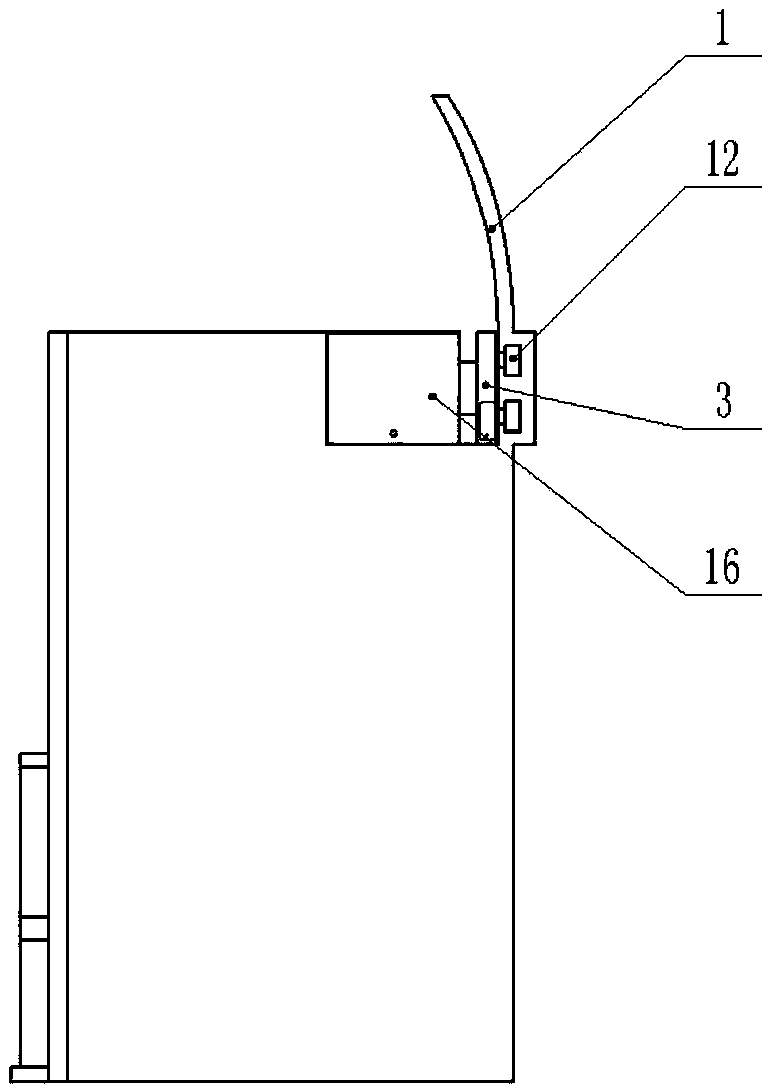

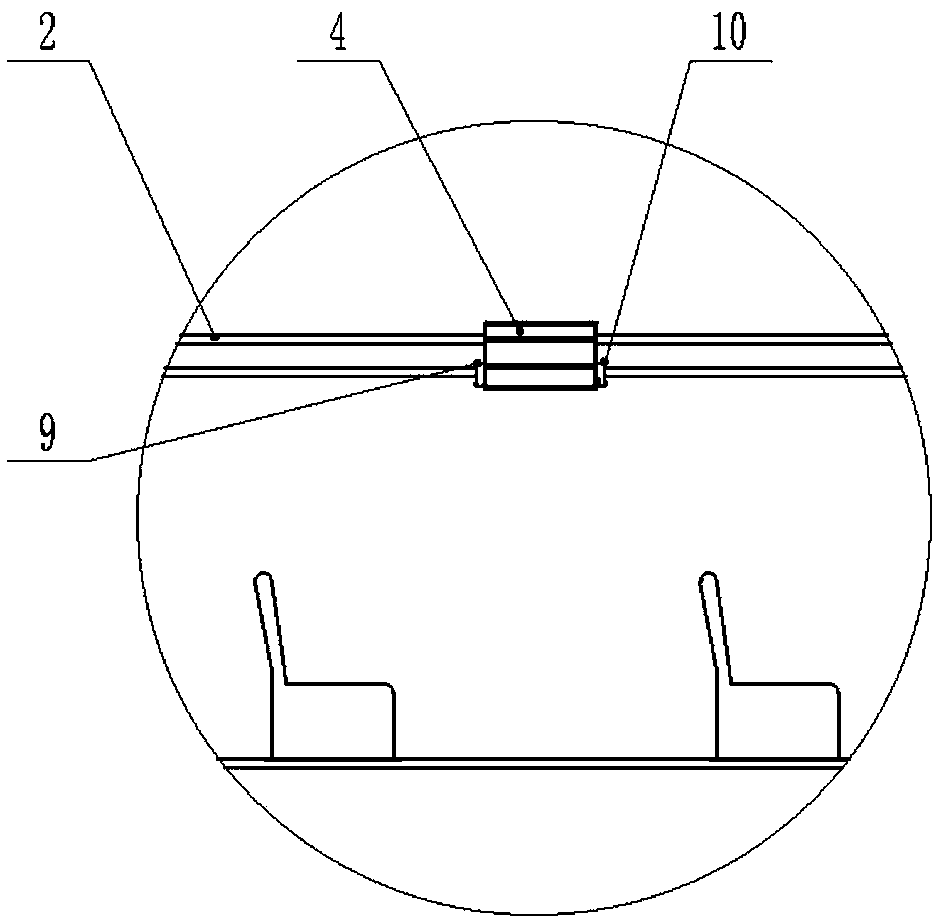

[0022] An article conveying device in a cabin is composed of a cabin roof 1, a power slide rail groove 2, a dynamic positioning module 3, a loading platform 4, a cabin floor 7, a cabin seat 8, and an assembly room 6. The power slide rail groove 2 is arranged on the side wall of the cabin at the lower part of the top 1, the power positioning module 3 is installed in the power slide rail groove 2, and the power positioning module 3 is close to the assembly room 6, a forward rotation motor 10 is installed on one side, and a reverse rotation motor 9 is installed symmetrically on the side of the dynamic positioning module 3 far away from the assembly chamber 6, and the dynamic positioning module 3 is equipped with and connected to the loading platform 4. The loading platform 4 slides in the power slide rail groove 2 through the dynamic positioning module 3 according to the needs of passengers, and the front part of the frontmost cabin seat 8 in the cabin is provided with the The as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com