Safety protection method of mining lifting cage

A technology for safety protection and lifting of tanks, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve problems such as the inability of the fall arrester to work, the lack of active maintenance devices for the main rope, and the lack of protection of the main rope. , to achieve the effect of improving the protection effect, delaying the aging time, and stable and reliable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

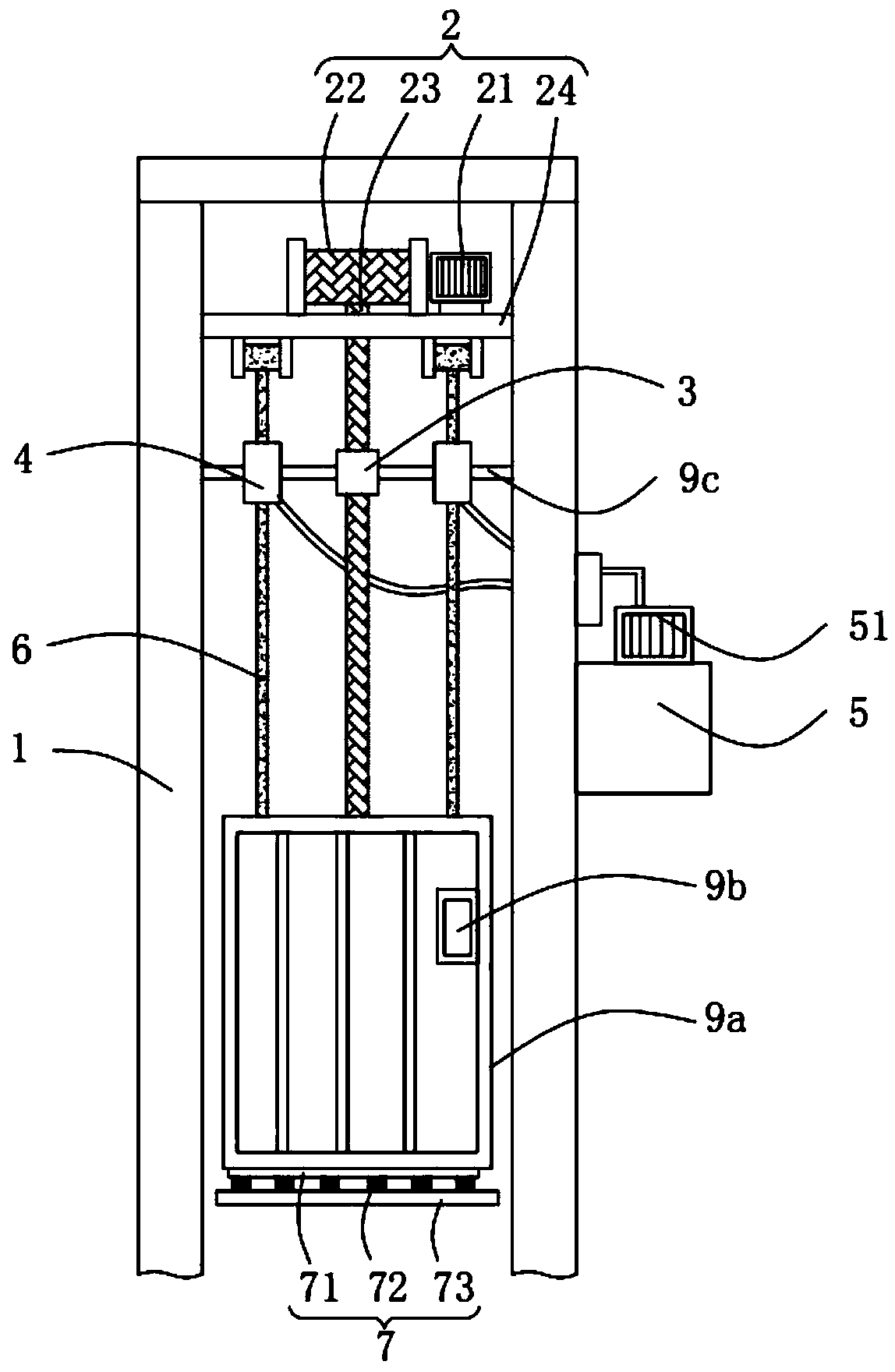

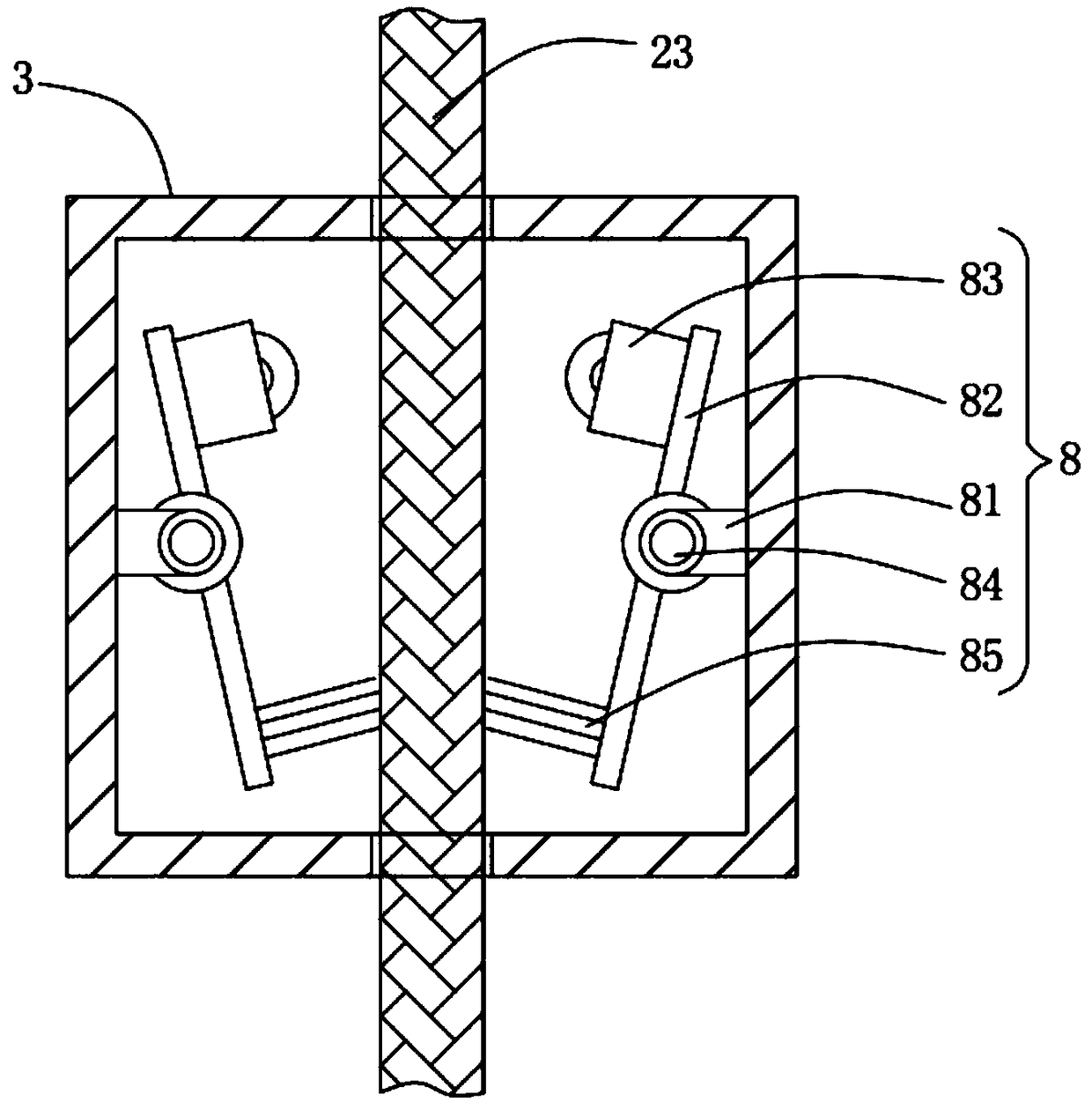

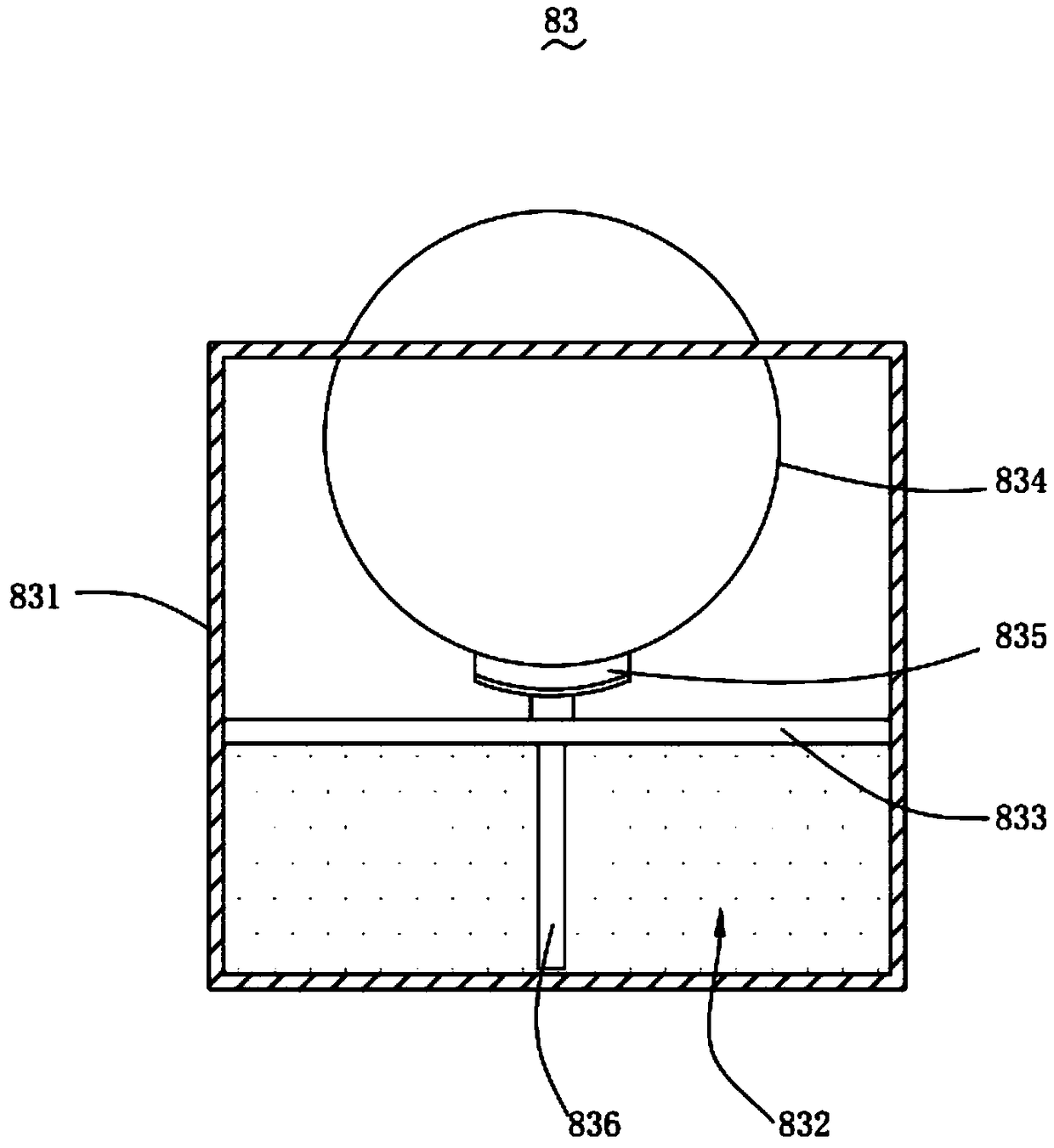

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0030] Such as Figure 1-Figure 7 Shown, a kind of mining hoisting cage safety protection method described in the present invention, this method comprises the following steps:

[0031] S1, an elastic rubber airbag is installed at the bottom of the lifting cage channel, and water is flushed into the elastic rubber airbag;

[0032] S2, on the basis of S1, a safety protection rope is connected to the top of the lifting cage;

[0033] The hoisting cage adopted in this method comprises an outer guard 1, a cage 9a and a switch box 9b, and also includes a lifting mechanism 2, a first box body 3, a second box body 4, a hydraulic oil tank 5, a protection mechanism 6, a buffer mechanism 7, Maintenance mechanism 8, pressing plate 9 and fixed rod 9c, descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com