Direct-buried pipe sleeving process production line

A production line, directly buried pipe technology, applied in the direction of lifting device, transportation and packaging, lifting frame, etc., can solve the problems of large forward resistance of the inner pipe, troublesome handling and hoisting operation of the directly buried pipe, low production efficiency of the set process, etc. Production efficiency, improved set production efficiency, smooth feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention.

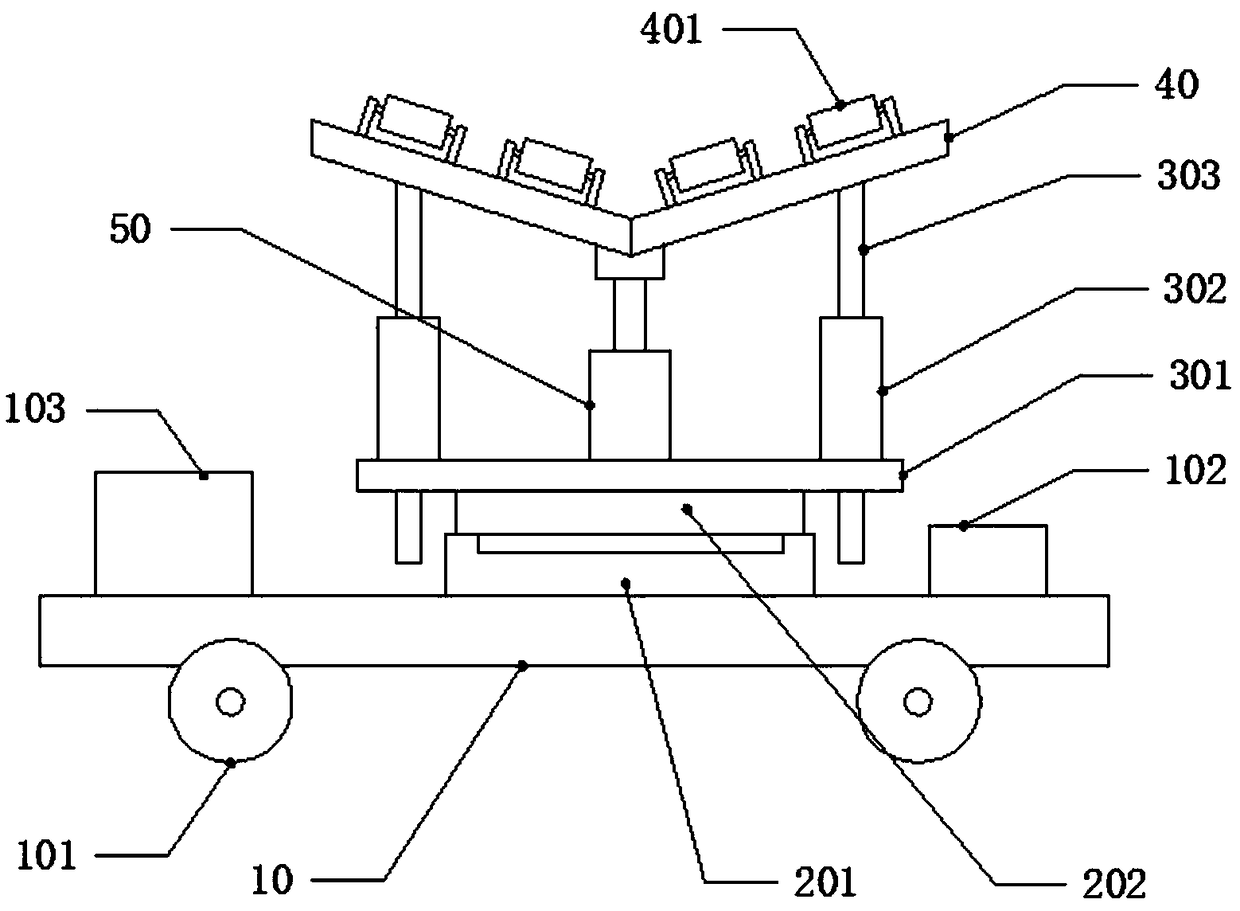

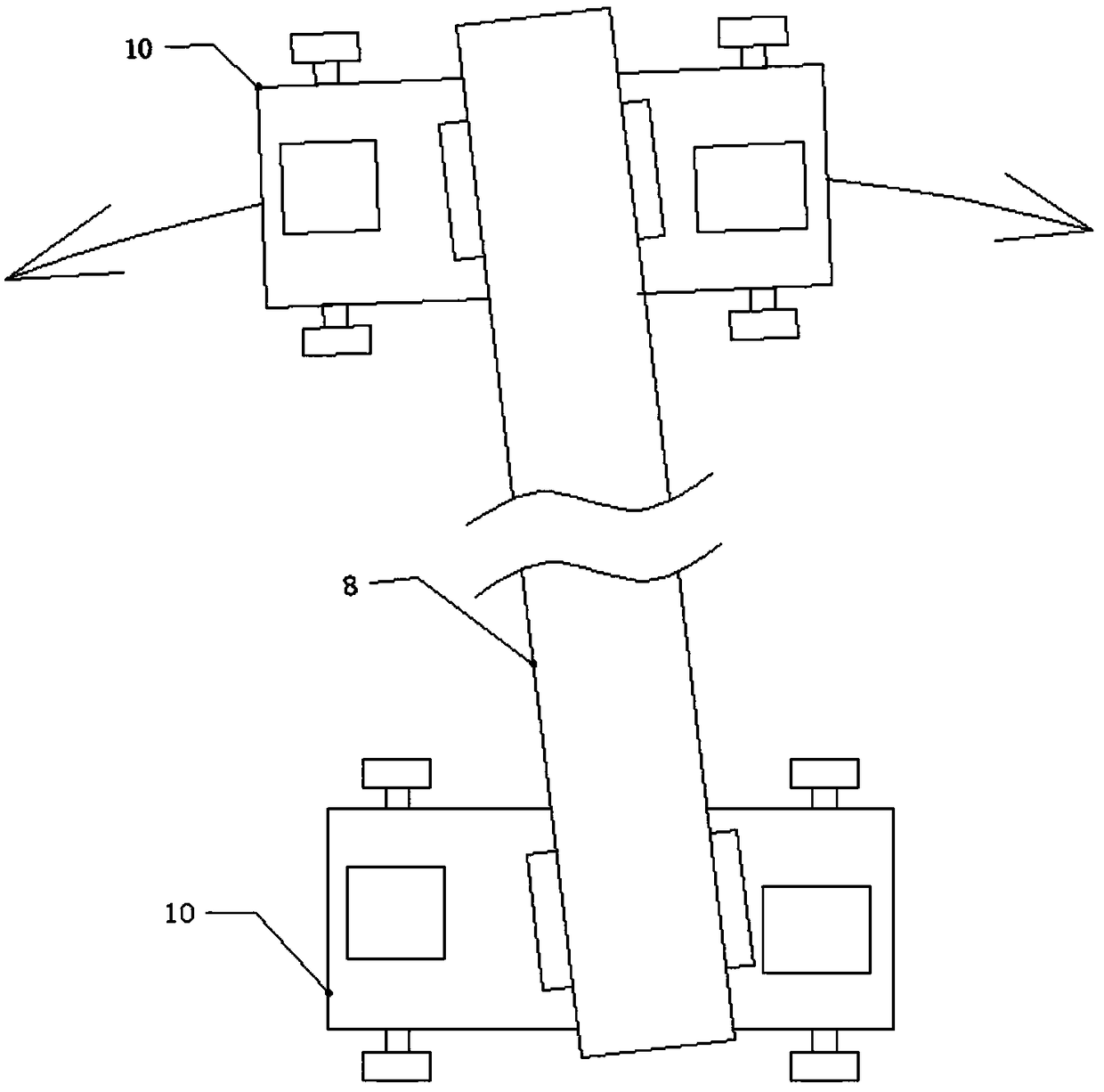

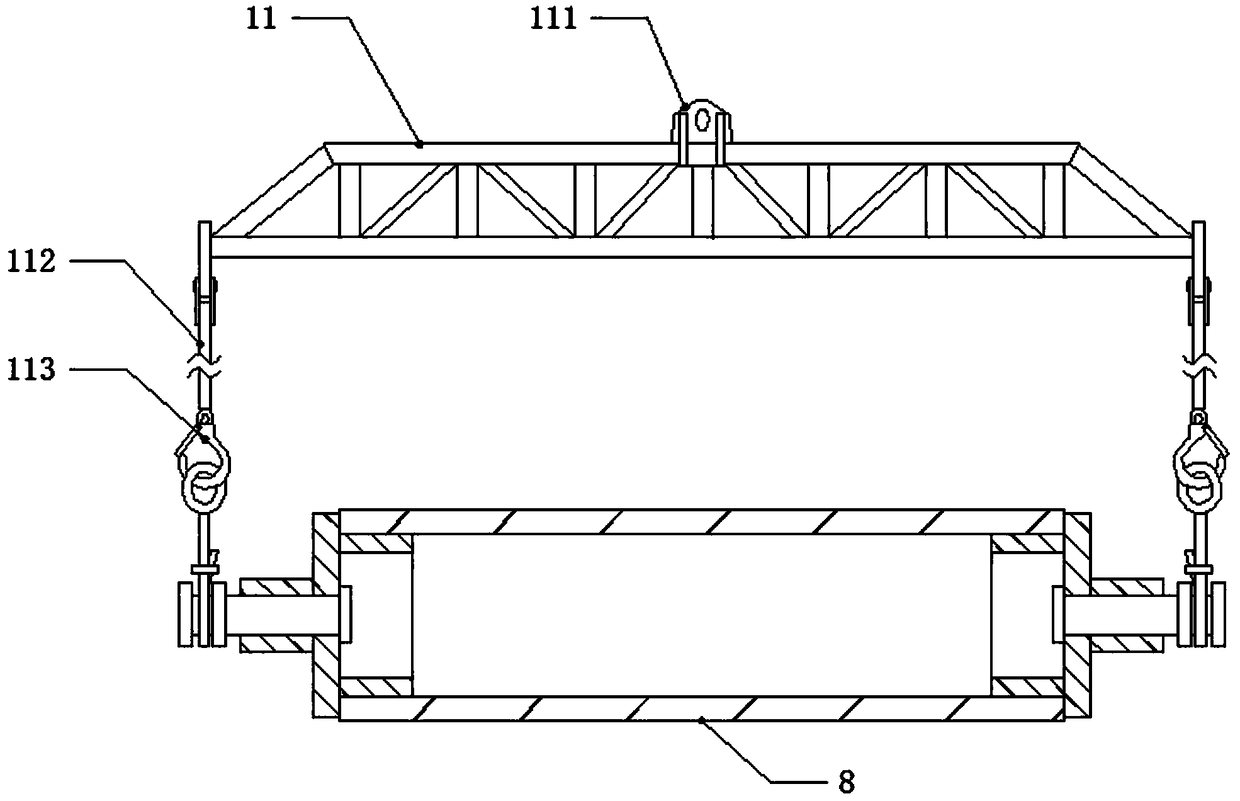

[0032] A direct-buried pipe packaged process production line, including a transport vehicle, a feeding spreader, a pretreatment workbench and packaged equipment,

[0033] The transport vehicle includes a trolley 10, traveling wheels 101, a traveling drive mechanism 102, a hydraulic station 103, a slewing support base 201, a rotary disc 202, a V-shaped bracket 40 and a hydraulic cylinder 50, and the traveling wheels 101 are arranged on the trolley 10 , the walking drive mechanism 102 drives the traveling wheel 101 to rotate to drive the trolley 10 to walk, the slewing support base 201 is fixedly installed on the upper side of the trolley 10, the slewing disc 202 is rotatably connected to the slewing support base 201, and the slewing disc 202 is fixedly installed with a bottom plate 301, the base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com