Vertical compost reactor as well as control method and control system thereof

A composting reactor and control system technology, which is applied in the fields of chemical fertilizer treatment control, preparation and application of organic fertilizers, and can solve problems such as uneven fermentation of materials, insufficient aeration, and excessive aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

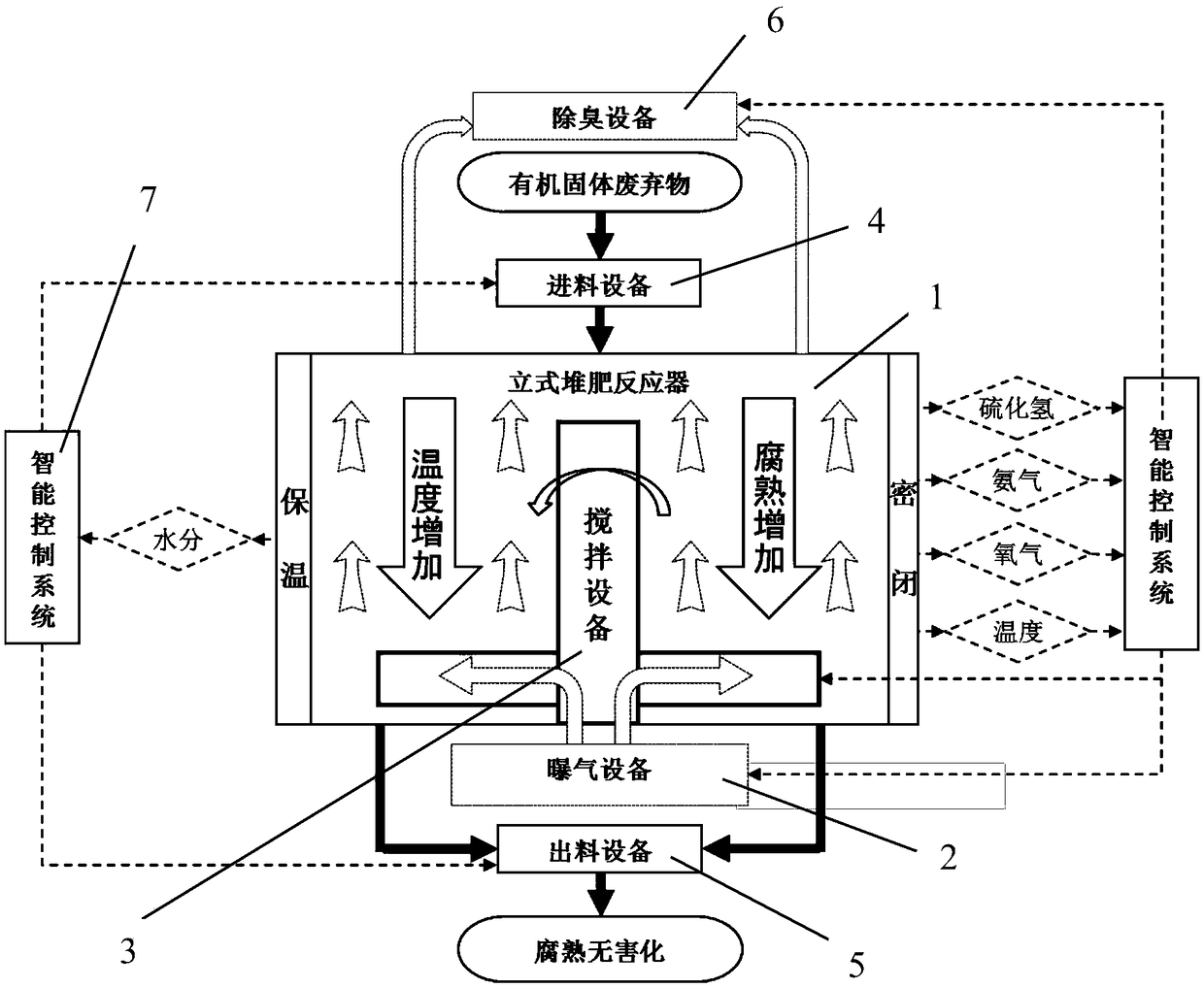

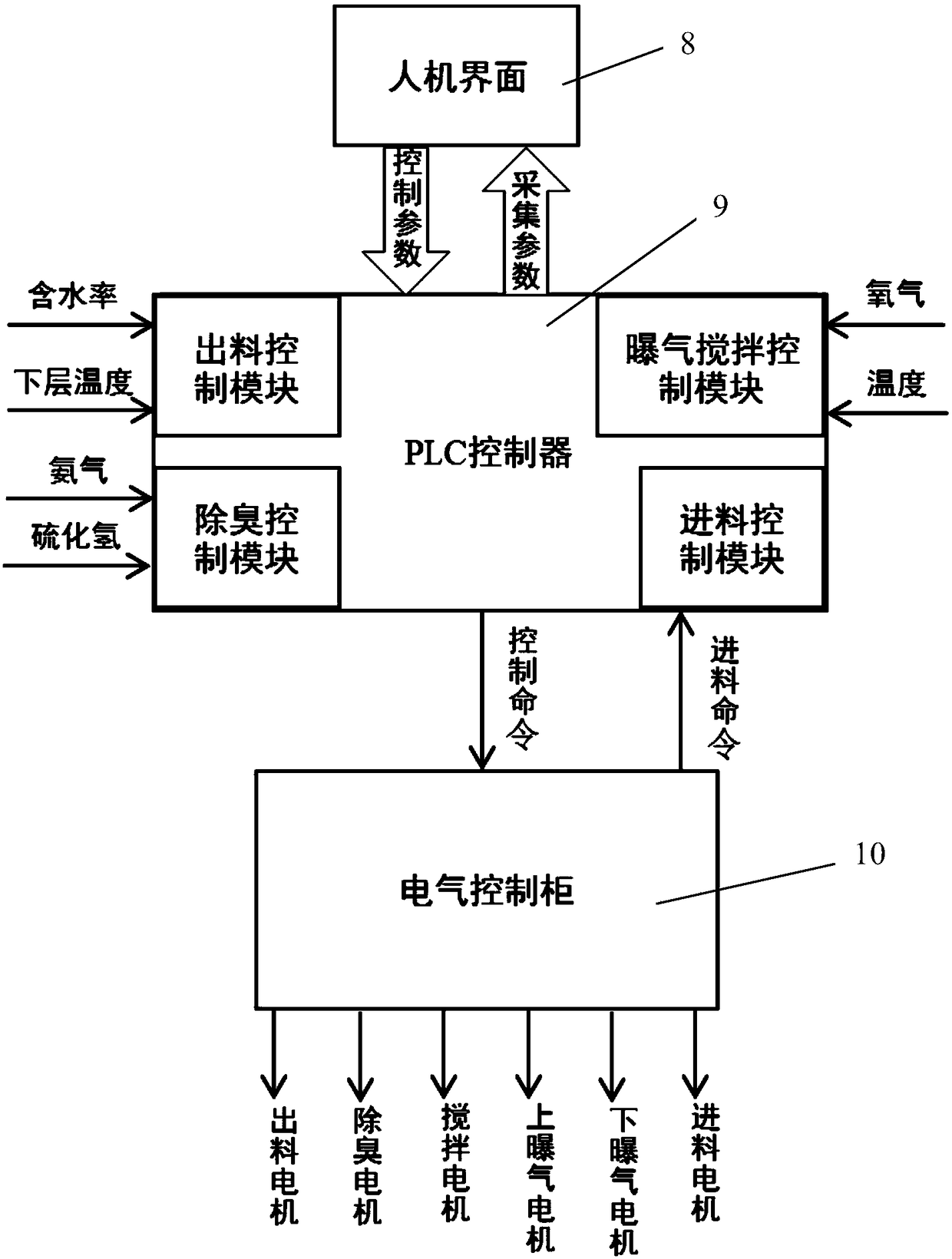

[0085] see figure 1 , figure 1 It is a working principle diagram of the control system 7 of the vertical composting reactor of the present invention. The names of the devices in the figure correspond to the devices in this embodiment, and will not be described one by one. The vertical composting reactor of the present invention comprises a composting reactor body 1, an aeration device 2, a stirring device 3, a feeding device 4, a discharging device 5, a deodorizing device 6 and a control system 7 , the composting reactor body 1 is respectively connected with the aeration device 2, the stirring device 3, the feeding and discharging device 5 and the deodorizing device 6, and the composting reactor body 1 is provided with an external insulation interlayer; the control system 7 includes: a low pressure Control cabinet 10; logic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com