Method of utilizing wastewater of marigold fermentation and dehydration to produce fertilizers

The technology of marigold and waste liquid is applied in the directions of liquid fertilizer, chemical instrument and method, fertilizer made of biological waste, etc. It can solve the problems of high cost of treatment of marigold fermentation dehydration waste liquid, etc. The effect of increasing crop yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 Fertilization utilization method of marigold fermentation dehydration waste liquid according to the present invention

[0020] The treatment method was introduced by taking the batch waste liquid with lactic acid content of 3.28g / L and total amino acid content of 1.06g / L in the fermentation dehydration waste liquid of marigold as an example.

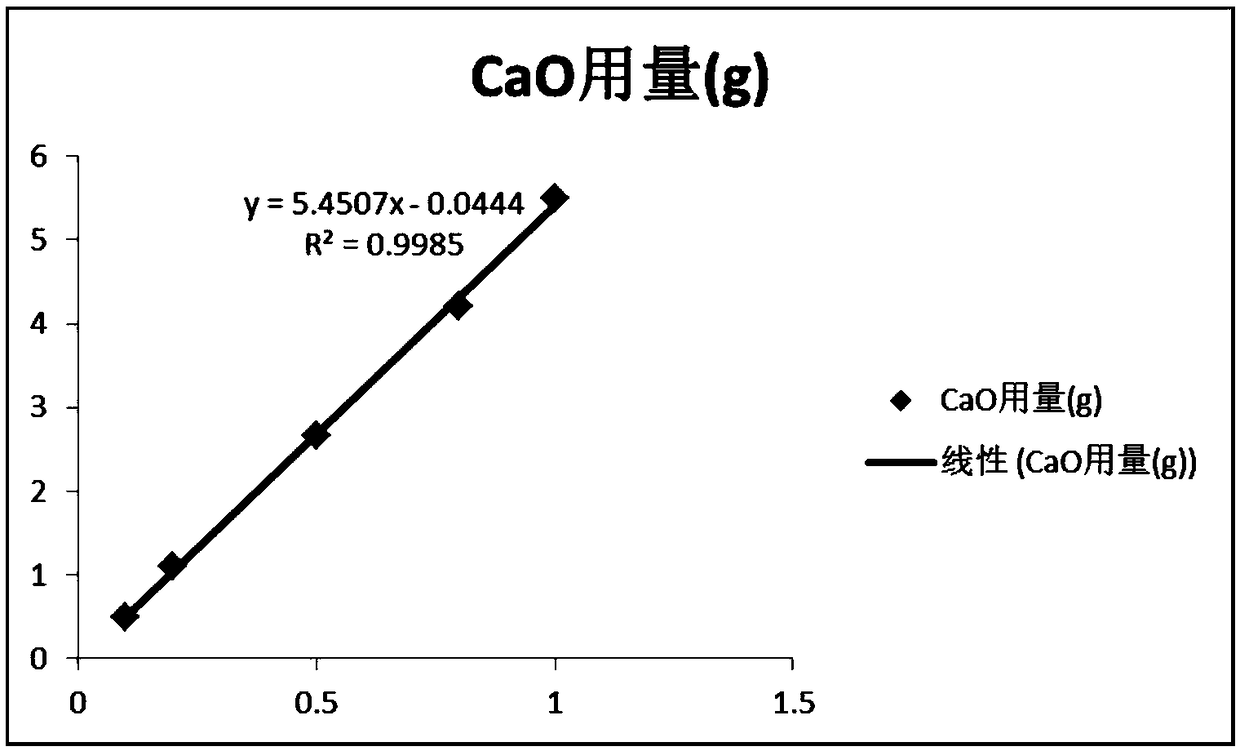

[0021] (1) Use a graduated cylinder to measure 100ml, 200ml, 500ml, 800ml, 1000ml of marigold fermentation dehydration waste liquid into a beaker, neutralize with quicklime (CaO) solid until the pH is 7.0; repeat the neutralization three times, the average amount of quicklime The values are as follows:

[0022] Table 1 The average dosage of CaO as neutralizer

[0023]

[0024] According to the above-mentioned data, take the marigold dehydration liquid volume (ml) as the abscissa, and take the average amount of CaO (g) as the ordinate, and calculate the linear equation of the neutralization reaction as Y=5.4507 w...

Embodiment 2

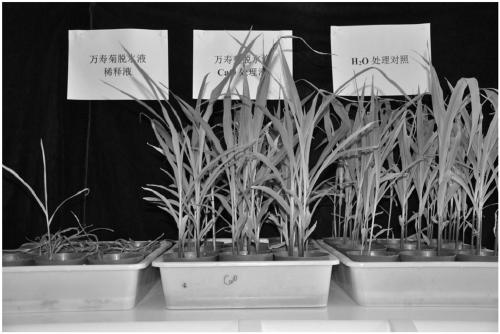

[0028] Example 2 Application of fertilization nutrient solution of marigold fermentation dehydration waste liquid in corn pot experiment

[0029] The corn variety "Xingnong 998" used for testing was used. Corn seeds of the same size and plumpness were taken, soaked in sterile water, stirred with a glass rod, and soaked for two hours so that the red coat was washed off. Sow seeds at 3-4cm from the surface of the pot soil, 4 plants per pot. When the first true leaf grows, irrigate with clear water as the control group (CK), irrigate the marigold fermentation and pressing dehydration liquid (dehydration liquid) as the comparison group, and fertilize the fertilization nutrient solution of the marigold fermentation dehydration waste liquid obtained in Example 1 Dilute 2-fold watering to be the test group, start to water the corn seedlings of different groups respectively, water 200ml in each pot, 10 pots in each group, water once every 15 days, and water continuously twice.

[003...

Embodiment 3

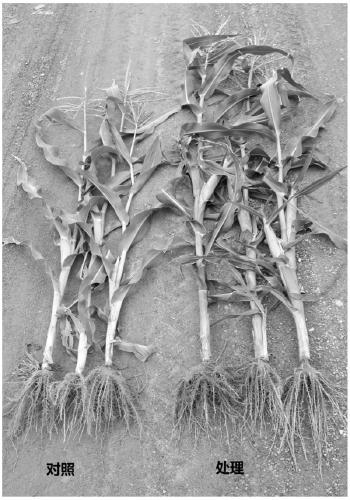

[0033] Example 3 Application of fertilization nutrient solution from marigold fermentation dehydration waste liquid in corn field experiment

[0034] The corn variety to be tested was "Xingnong 998". One month after sowing, a 5m×5m area was randomly selected in a 10-mu corn field with uniform growth and normal management. The fertilization nutrient solution obtained from the fertilization and dehydration waste liquid of marigold obtained in Example 1 was diluted 5 times, and then the experimental area was irrigated, and the remaining areas were irrigated with clear water as a control group (CK). One month later, the effects of two groups of different treatment methods on the plant height, stem diameter, chlorophyll and other indicators of corn were measured, and it was found that the stem diameter of the Wanshou fermentation dehydration waste liquid fertilization and utilization nutrient solution obtained by using the present invention was 15.12% higher than that of the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com