Iridescent pearlescent leather and preparation method thereof

A pearlescent and leather technology, applied in the field of iridescent pearlescent leather and its preparation, can solve the problems that the appearance of the leather surface does not play a big role, and the brightness of the leather surface is difficult to achieve, so as to improve fluency, transparency and visual effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

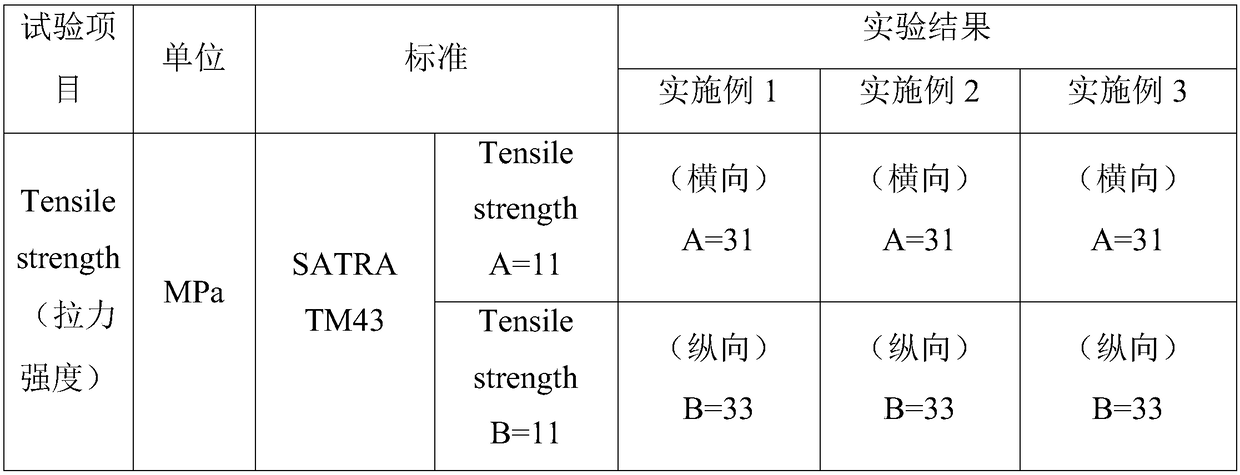

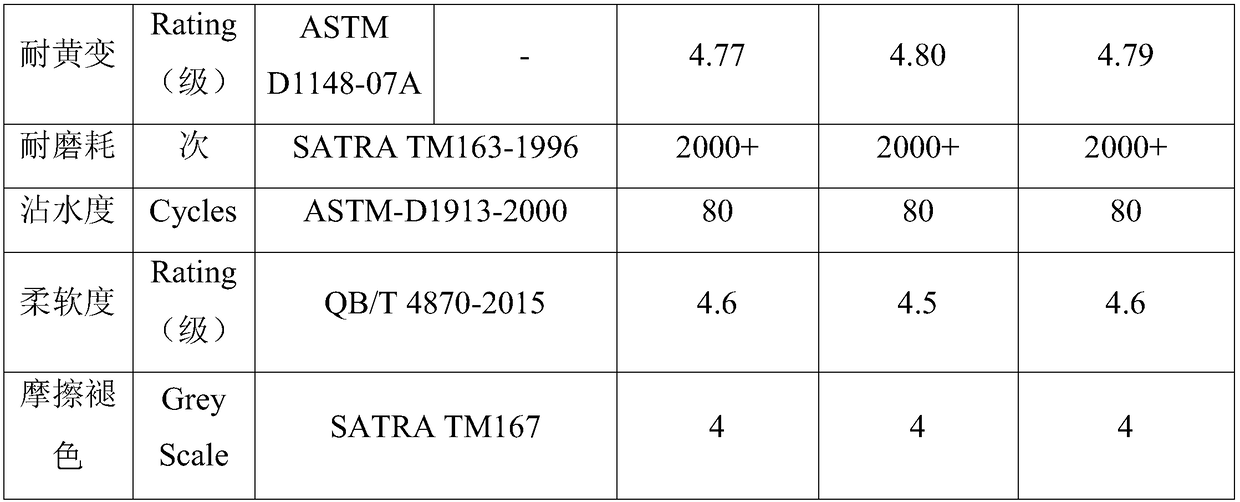

Examples

Embodiment 1

[0035] Iridescent pearl leather, including leather and coating, said coating includes the following components in terms of leather mass percentage: 7% of the first coating, 12% of the second coating and 12% of the third coating, wherein, The third coating, the second coating and the first coating are sequentially attached to the leather.

[0036] The first coating comprises the following components in terms of leather mass percentage: 6% maleic anhydride, 7% sodium sulfite, 8% sodium 2-hydroxyethanesulfonate, and 9% butanone;

[0037] The second coating comprises the following components in terms of leather mass percentage: 2% toner, 13% polyvinyl acetate; the toner is iridescent color powder.

[0038] The third coating includes the following components in terms of leather weight percentage: 0.7% of pearl powder, 8% of polyacrylamide, and 3% of polymethyl methacrylate.

[0039] The preparation method of described iridescent pearl leather, comprises the steps:

[0040] Step 1...

Embodiment 2

[0056] Iridescent pearl leather, including leather and coating, said coating includes the following components in terms of leather mass percentage: 8% of the first coating, 14% of the second coating and 14% of the third coating, wherein, The third coating, the second coating and the first coating are sequentially attached to the leather.

[0057] The first coating comprises the following components in terms of leather mass percentage: 8% maleic anhydride, 8% sodium sulfite, 9% sodium 2-hydroxyethanesulfonate, and 11% methyl ethyl ketone;

[0058] The second coating comprises the following components in terms of leather mass percentage: 3% toner, 14% polyvinyl acetate; the toner is iridescent color powder.

[0059] The third coating includes the following components in terms of leather weight percentage: 0.8% of pearl powder, 9% of polyacrylamide, and 5% of polymethyl methacrylate.

[0060] The preparation method of described iridescent pearl leather, comprises the steps:

[00...

Embodiment 3

[0077] Iridescent pearl leather, including leather and coating, said coating includes the following components in terms of leather mass percentage: 10% of the first coating, 15% of the second coating and 15% of the third coating, wherein, The third coating, the second coating and the first coating are sequentially attached to the leather.

[0078] The first coating comprises the following components in terms of leather mass percentage: 10% maleic anhydride, 9% sodium sulfite, 11% sodium 2-hydroxyethanesulfonate, and 13% butanone;

[0079] The second coating comprises the following components in terms of leather mass percentage: 3% toner, 16% polyvinyl acetate; the toner is iridescent color powder.

[0080] The third coating includes the following components in terms of leather weight percentage: 1.0% of pearl powder, 9% of polyacrylamide, and 6% of polymethyl methacrylate.

[0081] The preparation method of described iridescent pearl leather, comprises the steps:

[0082] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com