Blast furnace burden distribution method and device

A technology for distributing and charging charges, which is applied in the field of blast furnace distribution methods and devices, can solve the problems of low gas utilization rate, insufficient air permeability in blast furnace block belts and soft melting areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

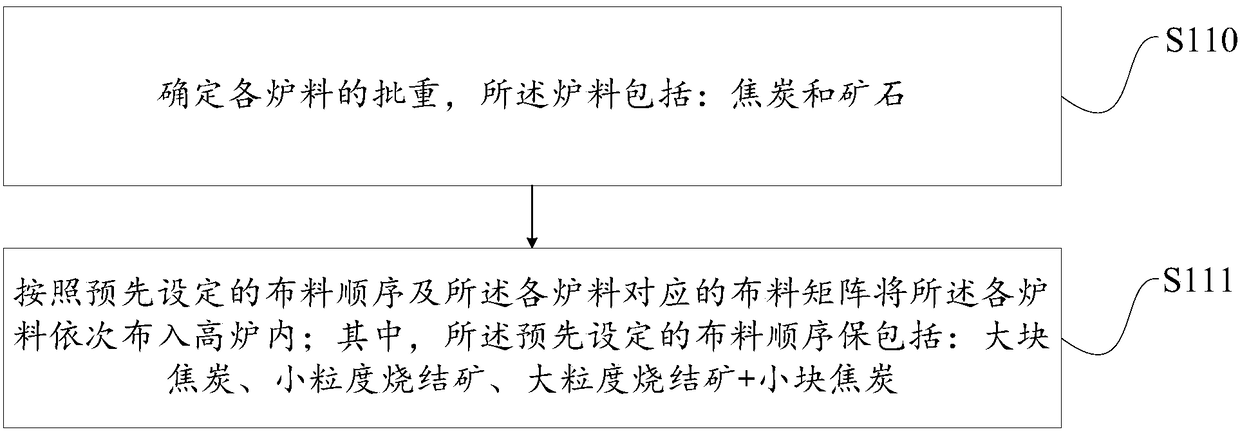

[0029] This embodiment provides a blast furnace cloth distribution method, such as figure 1 As shown, the method includes:

[0030] S110, determining the batch weight of each charge, the charge comprising: coke and ore;

[0031] Here, coke includes: small-sized coke and large-sized coke; ore includes: large-sized sintered ore, small-sized sintered ore, pellets, and lump ore. Among them, the particle size of large coke is greater than 25mm, the particle size of small coke is 12-25mm, the particle size of large-size sintered ore is greater than 11mm, and the particle size of small-sized sintered ore is 4-11mm.

[0032] Because blast furnaces of different specifications have different production requirements, the required charge and batch weight are also different. In this embodiment, it is based on the batch weight (coke batch) of the effective volume coke of the blast furnace. For example, the thickness of the coke batch at the throat of the blast furnace is not less than 0.5...

Embodiment 2

[0047] This embodiment provides a blast furnace distribution device, such as figure 2 As shown, the device includes: a determination unit 21 and a cloth unit 22; wherein,

[0048] Determining unit 21 is used to determine the batch weight of each burden, and described burden comprises: coke and ore; Here, coke comprises: coke of small piece and large coke; and lump ore, etc. Among them, the particle size of large coke is greater than 25mm, the particle size of small coke is 12-25mm, the particle size of large-size sintered ore is greater than 11mm, and the particle size of small-sized sintered ore is 4-11mm.

[0049] Because blast furnaces of different specifications have different production requirements, the required charge and batch weight are also different. In this embodiment, it is based on the batch weight (coke batch) of the effective volume coke of the blast furnace. For example, the thickness of the coke batch at the throat of the blast furnace is not less than 0.5...

Embodiment 3

[0062] In practical application, when using the methods and devices provided in the above embodiments to distribute material into the blast furnace, the specific implementation is as follows:

[0063] With an effective volume of 3200m 3 Taking the blast furnace as an example, the determined charge and batch weight include: 18.8 tons of coke batch, including: 17 tons of large coke and 1.8 tons of small coke.

[0064] The batch weight of ore is 89.5 tons, including: 46 tons of large-sized sintered ore, 16.5 tons of small-sized sintered ore, 13.5 tons of pellets, and 13.5 tons of lump ore.

[0065] After determining the ore batch and the coke batch, according to the preset distribution sequence and the distribution matrix corresponding to each charge, the charges are sequentially distributed into the blast furnace. The preset distribution sequence includes: large coke, small Grain size sinter, large size sinter + small piece coke; that is, first put in large piece coke, then put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com