Water-resistant medical cotton fabric resistant to protein contamination and preparation method thereof

A cotton fabric, washable technology, applied in the field of medical textile materials, to achieve good segment flexibility, good protein pollution resistance, prevent adsorption and value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

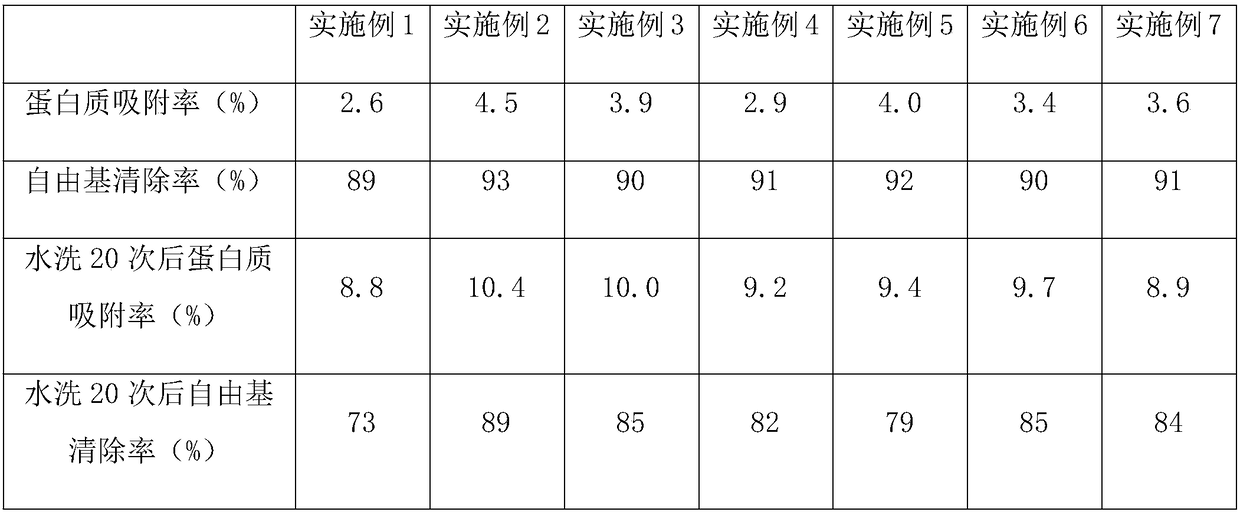

Examples

Example Embodiment

[0023] Example 1:

[0024] (1) After the medical cotton fabric is activated by a sodium hydroxide solution at 50°C for 5 min, according to the mass ratio of the medical cotton fabric and triacetyl gallic acid chloride is 1:0.75, fully immersed in the triacetyl gallic acid chloride solution, according to The ratio of pyridine catalyst to triacetylgalloyl chloride is 0.9 mL: 1.5 g, and pyridine catalyst is added dropwise. After 1 h of constant temperature oscillation at 50 °C, acetate solution is added dropwise to adjust the pH value of the system to 9.5, cooling and washing, drying to obtain anti-oxidative medical cotton fabrics.

[0025] (2) The anti-oxidative medical cotton fabric was immersed in Tris buffer containing 50 mM dopamine, shaken and reacted at room temperature for 1 hour, and then taken out to obtain a polydopamine-modified medical cotton fabric.

[0026] (3) coating the surface of the polydopamine-modified medical cotton fabric with a polyethylene glycol soluti...

Example Embodiment

[0027] Example 2:

[0028] (1) After the medical cotton fabric is activated by a sodium hydroxide solution at 60°C for 10 min, according to the mass ratio of the medical cotton fabric and triacetyl gallic acid chloride is 1:0.9, fully immersed in the triacetyl gallic acid chloride solution, according to The ratio of pyridine catalyst to triacetylgalloyl chloride is 1.2mL: 2g, add pyridine catalyst dropwise, after constant temperature shaking at 70°C for 3h, add acetate solution dropwise, adjust the pH value of the system to 10, cool and wash, bake dried to obtain antioxidant medical cotton fabric.

[0029] (2) The anti-oxidative medical cotton fabric was immersed in a Tris buffer containing 60 mM dopamine, shaken and reacted at room temperature for 3 hours, and then taken out to obtain a polydopamine-modified medical cotton fabric.

[0030] (3) coating the surface of the polydopamine-modified medical cotton fabric with a polyethylene glycol solution, wherein the polyethylene ...

Example Embodiment

[0031] Example 3:

[0032] (1) After the medical cotton fabric is activated by a sodium hydroxide solution at 50°C for 10 min, according to the mass ratio of the medical cotton fabric and triacetyl gallic acid chloride is 1:0.75, fully immersed in the triacetyl gallic acid chloride solution, according to The ratio of pyridine catalyst to triacetylgalloyl chloride is 1.2mL: 1.5g, add pyridine catalyst dropwise, after constant temperature shaking at 70°C for 1h, add acetate solution dropwise, adjust the pH value of the system to 10, cool and wash, drying to obtain anti-oxidative medical cotton fabrics.

[0033] (2) The anti-oxidative medical cotton fabric was immersed in Tris buffer containing 50 mM dopamine, shaken for 3 hours at room temperature and taken out to obtain a polydopamine-modified medical cotton fabric.

[0034] (3) coating the surface of the polydopamine-modified medical cotton fabric with a polyethylene glycol solution, wherein the polyethylene glycol solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com