A kind of multi-component uv-led light curing screen ink for glass substrate and preparation method thereof

A UV-LED and glass substrate technology, applied in ink, applications, household appliances, etc., can solve the problems of incomplete curing of the printed pattern surface, low ink film cross-linking degree, poor solvent resistance of the ink film, etc., and achieve improvement Adhesion fastness, improving the degree of cross-linking and curing, excellent hydrolysis resistance and acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] (1) Preparation of hyperbranched polyglycidol

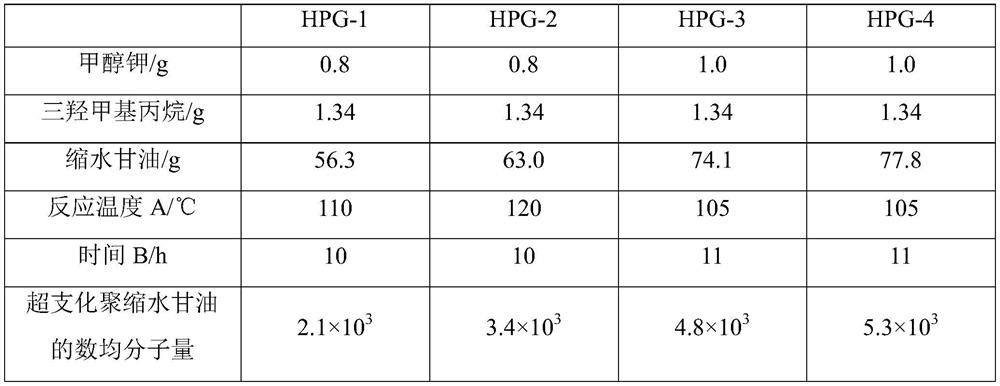

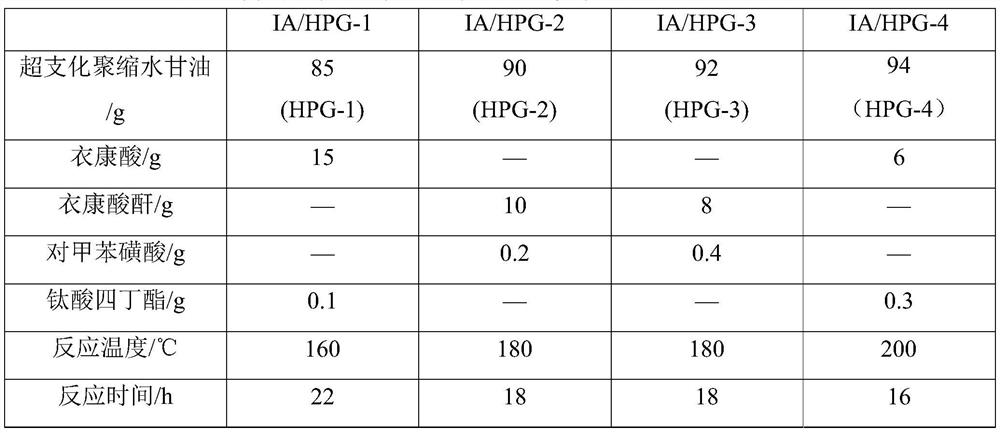

[0041] The hyperbranched polyglycidol used in this example is commercially available, and can also be prepared through the following steps. The preparation raw materials, proportioning, reaction conditions and product number average molecular weight are as shown in Table 1:

[0042] Ventilate nitrogen, add trimethylolpropane and potassium methoxide dissolved in methanol successively in the reaction kettle, raise the temperature to 50-60°C to volatilize the methanol; then raise the temperature to reaction temperature A, slowly add glycidol dropwise in time B, drop After the addition, keep warm for 0.5-1 hour; cool down, dissolve the product with methanol, precipitate with acetone, and dry to obtain hyperbranched polyglycidol.

[0043] The number average molecular weight of the obtained hyperbranched polyglycidol was determined by gel permeation chromatography.

[0044] Table 1 prepares the raw material and proportioning of h...

Embodiment 1

[0053] This embodiment prepares the raw materials and proportioning ratio of A component in the black multi-component UV-LED photocurable screen ink as shown in Table 3:

[0054] Table 3 Raw materials and proportions of component A in black multi-component UV-LED photocurable screen ink

[0055]

[0056]

[0057] The preparation method of the black multi-component UV-LED photocurable screen ink of the present embodiment comprises the following steps:

[0058] S1. Mix itaconic acid modified hyperbranched polyglycidol, epoxy acrylate oligomer, isobornyl methacrylate and tetrahydrofuran acrylate;

[0059] S2. Add pigments, fillers and additives, and grind until the fineness is below 25 μm;

[0060] S3. Mix N,N-methylenebisacrylamide and trimethylolpropane, add a photoinitiator and stir to dissolve, then add it to the mixture in step S2, stir evenly, and obtain component A;

[0061] S4. Before printing, take 100 parts of component A obtained in step S3, add 5 parts of 3-me...

Embodiment 2

[0063] This example prepares the raw materials and proportioning ratio of A component in the white multi-component UV-LED photocurable screen ink as shown in Table 4:

[0064] Table 4 Raw materials and proportions of component A in white multi-component UV-LED photocurable screen ink

[0065]

[0066]

[0067] The preparation method of the white multi-component UV-LED photocurable screen ink of the present embodiment comprises the following steps:

[0068] S1. Mix itaconic acid-modified hyperbranched polyglycidol, epoxy acrylate oligomer, isobornyl acrylate, tetrahydrofuran methacrylate and acryloylmorpholine evenly;

[0069] S2. Add pigments, fillers and additives, and grind until the fineness is below 25 μm;

[0070] S3. Mixing tripropylene glycol diacrylate and propoxylated trimethylolpropane triacrylate, adding a photoinitiator and stirring to dissolve, then adding to the mixture in step S2, stirring evenly to obtain component A;

[0071] S4. Before printing, take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com