A high elongation and high modulus polyether gas generating agent

A gas generating agent and high elongation technology, which is applied in the generation of compressed gas, offensive equipment, explosives, etc., can solve the problems of grain structure damage, poor mechanical properties, low elongation, etc., to improve energy and low temperature performance Excellent, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

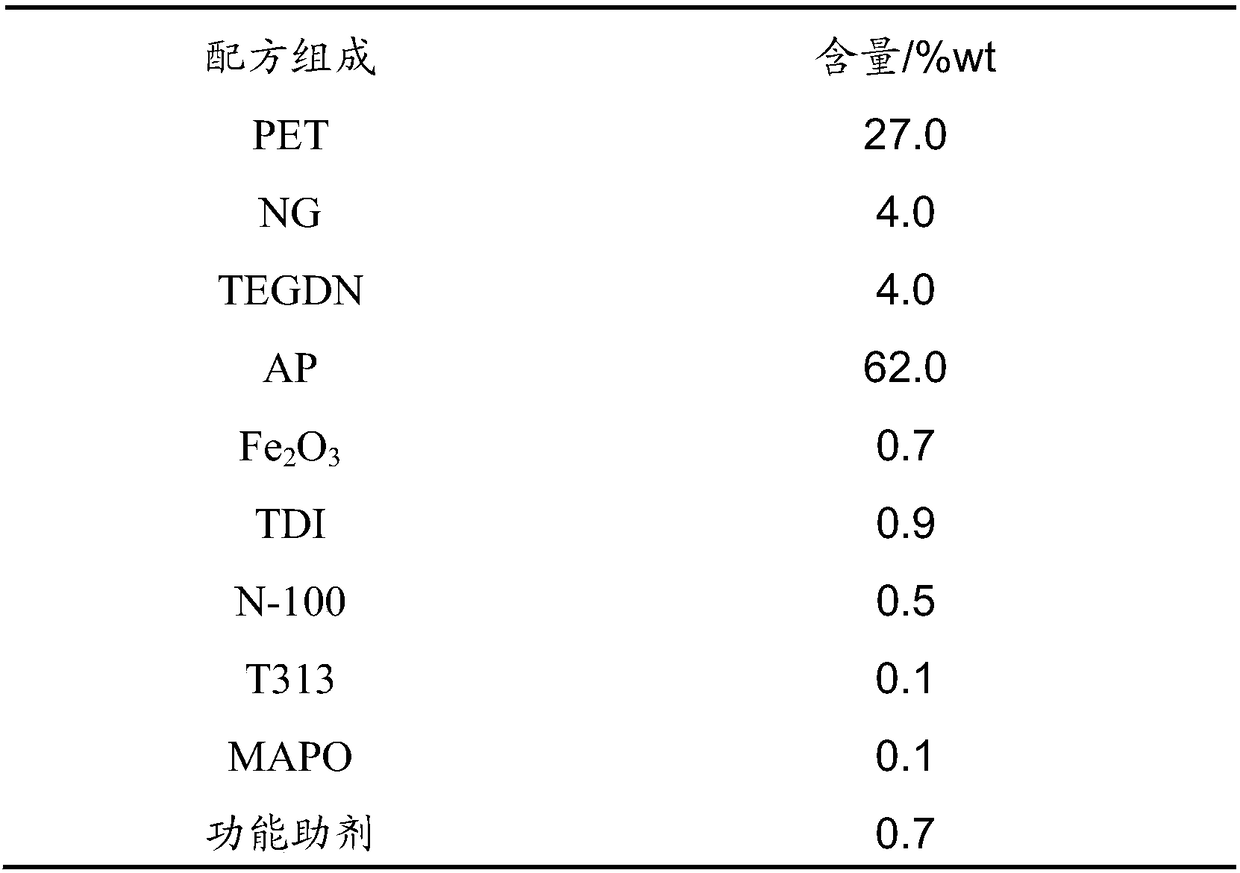

[0034] (1) Propellant composition (mass percent %)

[0035]

[0036] Wherein the above-mentioned functional additives include:

[0037]

[0038] (2) Propellant performance

[0039] Mechanical properties: 25°C: ε m =110.3%, E=5.8MPa, σ m =0.92MPa; 70℃: ε m =52.3%, -40°C: ε m = 350%

[0040] Residue content: 2.0%

[0041] Measured combustion temperature: 1645K

[0042] Combustion performance: r (6.86MPa) = 8.3mm / s, n = 0.28 (3-9MPa)

[0043] Theoretical specific impulse: 1995.5N.s / kg

Embodiment 2

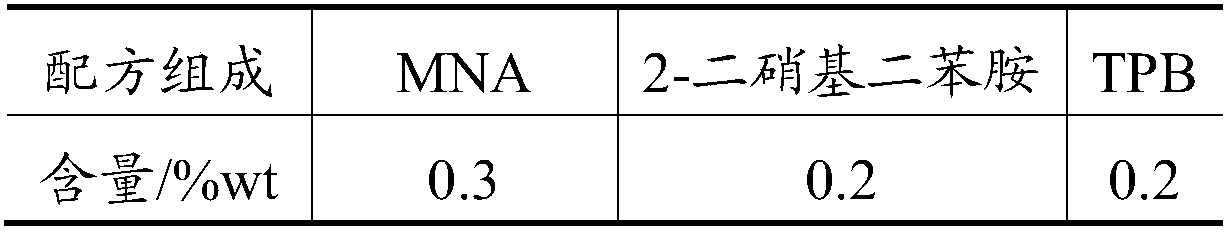

[0045] (1) Propellant composition (mass percent %)

[0046]

[0047] Wherein the above-mentioned functional additives include:

[0048]

[0049] (2) Propellant performance

[0050] Mechanical properties: 25°C: ε m =150.3%, E=4.7MPa, σ m =0.83MPa; 70℃: ε m =65.5%; -40°C: ε m =410%

[0051] Residue content: 2.3%

[0052] Measured combustion temperature: 1615K

[0053] Combustion performance: r(6.86MPa)=7.5mm / s, n=0.23(3-9MPa)

[0054] Theoretical specific impulse: 1984.7N.s / kg

Embodiment 3

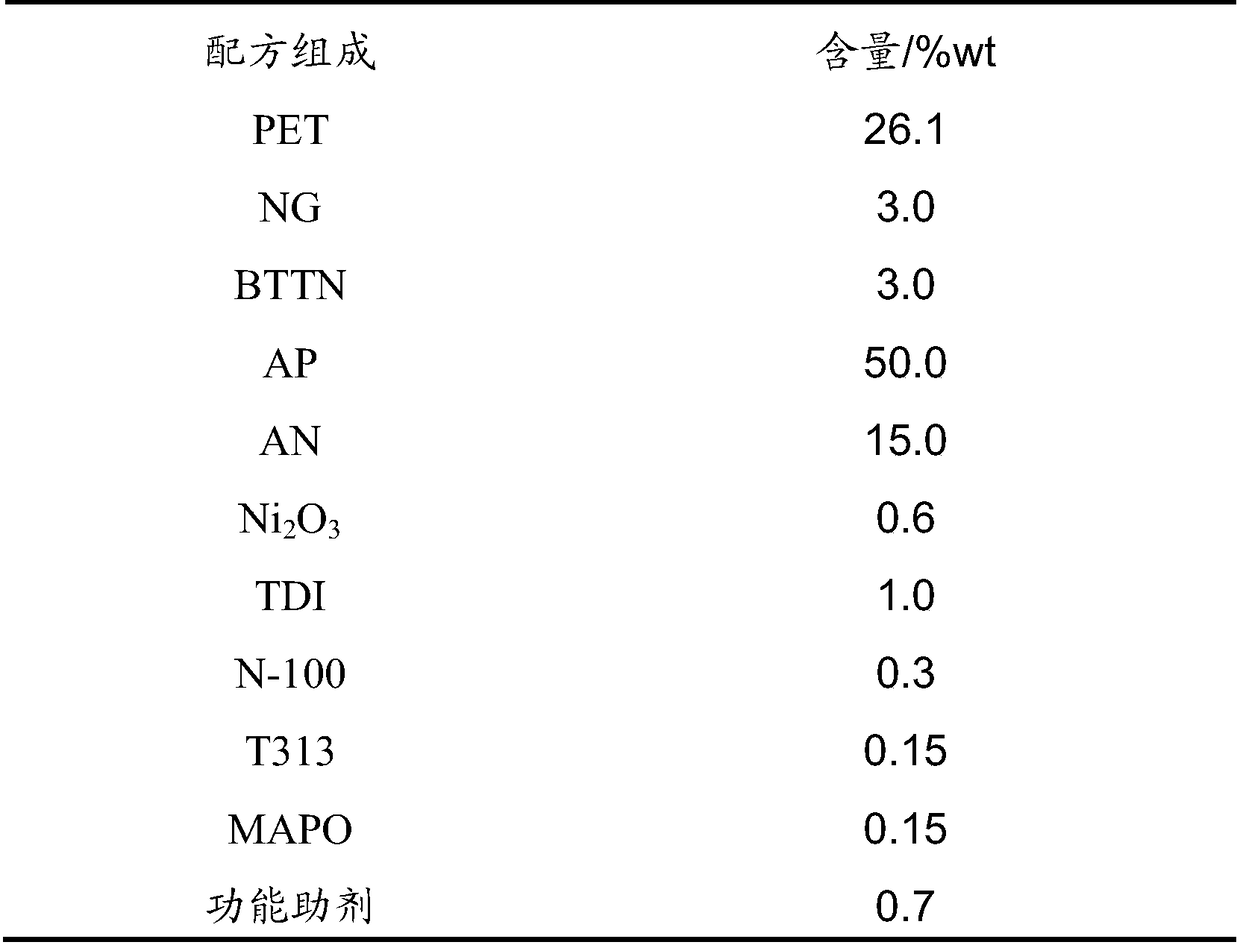

[0056] (1) Propellant composition:

[0057]

[0058] Wherein the above-mentioned functional additives include:

[0059]

[0060] (2) Propellant performance

[0061] Mechanical properties: 25°C: ε m =226.3%, E=3.0MPa, σ m =0.65MPa; 70℃: ε m =101.5%; -40°C: ε m =430%

[0062] Residue content: 2.4%

[0063] Measured combustion temperature: 1586K

[0064] Combustion performance: r(6.86MPa)=7.1mm / s, n=0.27(3-9MPa)

[0065] Theoretical specific impulse: 1978.6N.s / kg

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com