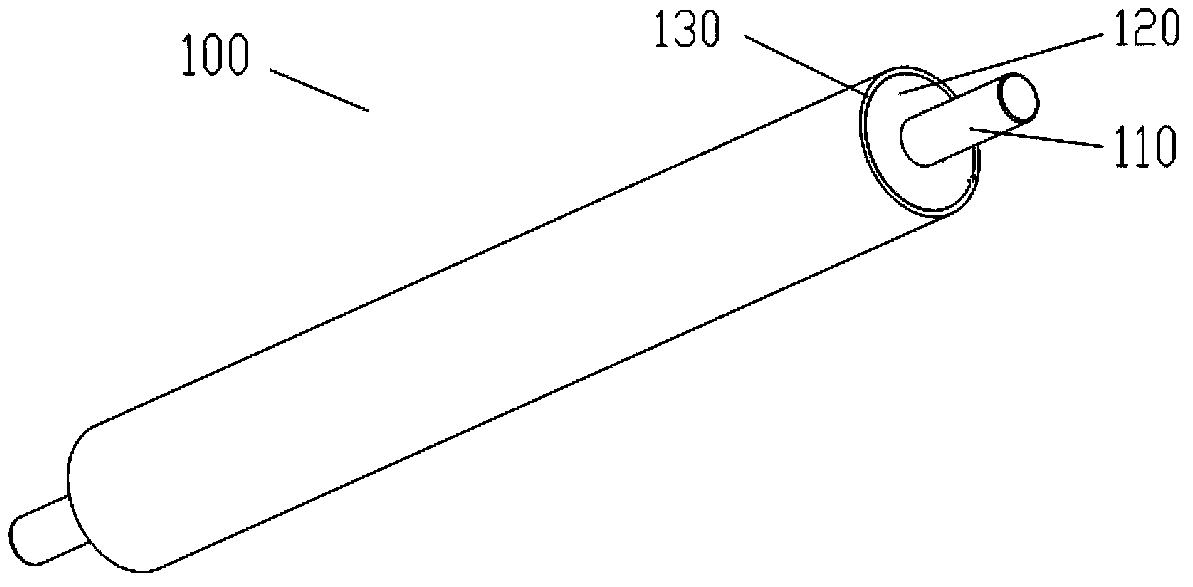

Elastomer roller, manufacturing method thereof, developing box and image forming device

A body roller and elastic technology, applied in the field of image formation, can solve the problems of inconvenient feeding, poor mixing compatibility, reduced processing efficiency, etc., and achieve the effects of not easy to change or be destroyed, good chain flexibility, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Pretreatment of shaft core:

[0077] The outer surface of a metal mandrel (SUM22) with an outer diameter of 8 mm was degreased with dehydrated ethyl acetate.

[0078] Formation of the elastic layer:

[0079] The basic materials used in the rubber composition are epichlorohydrin rubber and star-shaped comb-shaped butadiene-isoprene-styrene copolymer: (A f )n-C a (Provided by Dalian University of Technology or prepared with reference to the method in CN101157743B). In the formation of copolymers (A f )n-C a Among the monomers, the mass ratio of butadiene, isoprene and styrene is 40:40:20. Gel Permeation chromatography (Gel Permeation chromatography, GPC) analysis number average molecular weight Mn is 48500, weight average molecular weight Mw is 108200, molecular weight distribution index HI is 2.23, C a Residues for epoxidized liquid star polybutadiene seed trees.

[0080] 92 parts by mass of epichlorohydrin rubber (trade name: Hydrin T3106; produced by Zeon Co...

Embodiment 2

[0085] Formation of the adhesive layer:

[0086] Adhesives (trade names: Chemlok205 and Chemlok233; produced by Shanghai Lord Chemical Co., Ltd.) were used to arrange the outer layer of the shaft core in Example 1 according to the process recommended by the adhesive product to obtain a shaft core with an adhesive layer.

[0087] Formation of the elastic layer:

[0088] The basic materials used in the rubber composition are epichlorohydrin rubber and star-shaped comb polybutadiene: (A a )n-C a (Provided by Dalian University of Technology or prepared with reference to the method in CN101157743B). The number average molecular weight Mn analyzed by GPC is 35400, the weight average molecular weight Mw is 95900, and the molecular weight distribution index HI is 2.71, C a Residues for epoxidized liquid star polybutadiene seed trees.

[0089] 95 parts by mass of epichlorohydrin rubber and 5 parts by mass of star-shaped comb-shaped polybutadiene were mixed to form a base materi...

Embodiment 3

[0091] The basic material used in the rubber composition forming the elastic layer is epichlorohydrin rubber and star-shaped comb-shaped butadiene-styrene copolymer: (A d )n-C a (Dalian University of Technology provides or prepares with reference to the method in CN101157743B); Wherein, in forming copolymer (A d )n-C a Among the monomers, the mass ratio of butadiene and styrene is 75:25. The number average molecular weight Mn analyzed by GPC is 52100, the weight average molecular weight Mw is 113600, and the molecular weight distribution index HI is 2.18, C a Residues for epoxidized liquid star polybutadiene seed trees.

[0092] 92 parts by mass of epichlorohydrin rubber and 8 parts by mass of star-shaped comb-shaped butadiene-styrene are mixed to form the base material, and the rest are made into a developing roller according to the same raw materials and methods as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com