A kind of preparation method of butyl rubber/polylactic acid graft polymer

A technology of butyl rubber and graft copolymer, applied in the preparation of butyl rubber/polylactic acid graft polymer and the preparation of modified polylactic acid, can solve the problems of brittle fracture of polylactic acid and difficulty in forming polylactic acid film, etc. , to achieve good chain flexibility, improved toughness and processability, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

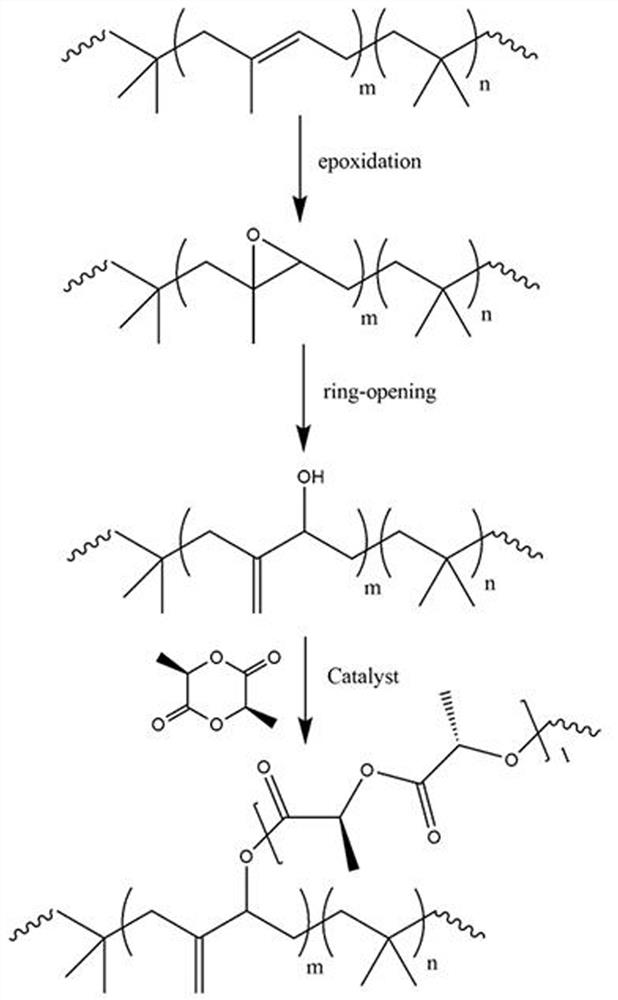

[0031] Such as figure 1 Shown, a kind of preparation method of butyl rubber / polylactic acid graft polymer comprises the following steps:

[0032] a. Take 10 g of butyl rubber with an unsaturation of 0.5% (0.89 mmol of isoprene unit, number average molecular weight of 239,000, molecular weight distribution of 2.02), completely dissolve in 800 ml of toluene, and keep the temperature at 30 o C, under stirring, add m-chloroperoxybenzoic acid toluene solution (8.9mmol, 100ml), the reaction time is 6 hours, the product is precipitated with a large amount of ethanol and dried in vacuum, and dried to obtain epoxidized butyl rubber; epoxy rate> 99 %. The epoxy butyl rubber yield is 95%.

[0033] b. Dissolve 5g epoxy butyl rubber (0.4 mmol epoxy group) completely in 150ml toluene, add 0.2ml 37% concentrated hydrochloric acid, react at room temperature for 6 hours, add a large amount of deionized water to wash, and vacuum dry to obtain hydroxyl Butyl rubber; the conversion rate of epo...

Embodiment 2

[0039] Such as figure 1 Shown, a kind of preparation method of butyl rubber / polylactic acid graft polymer comprises the following steps:

[0040] a. Take 10 g of butyl rubber with an unsaturation of 1% (1.78 mmol of isoprene units, number average molecular weight of 252,000, molecular weight distribution of 2.12), completely dissolve in 600 ml of toluene, and keep the temperature at 30 o C, under stirring, add m-chloroperoxybenzoic acid toluene solution (17.8mmol, 200ml), the reaction time is 3 hours, the product is precipitated with a large amount of ethanol and dried in vacuum, and dried to obtain epoxidized butyl rubber; epoxy rate> 99 %.

[0041] b. Dissolve 5g epoxy butyl rubber (0.85 mmol epoxy group) completely in 150ml toluene, add 0.4 ml 37% concentrated hydrochloric acid, react at room temperature for 6 hours, add a large amount of deionized water to wash, and vacuum dry to obtain hydroxyl Butyl rubber; the conversion rate of epoxy group to hydroxyl group is 80%.

...

Embodiment 3

[0044] Such as figure 1 Shown, a kind of preparation method of butyl rubber / polylactic acid graft polymer comprises the following steps:

[0045] a. Take 10 g of butyl rubber with an unsaturation degree of 1.5% (2.7 mmol of isoprene units, number average molecular weight of 239,000, molecular weight distribution of 2.21), completely dissolve in 1000 ml of toluene, and keep the temperature at 30 o C, under stirring, add m-chloroperoxybenzoic acid toluene solution (27 mmol, 200ml), the reaction time is 2 hours, the product is precipitated with a large amount of ethanol and dried in vacuo, and dried to obtain epoxidized butyl rubber; epoxy rate> 99 %.

[0046] b. Completely dissolve 5g epoxy butyl rubber (1.3mmol epoxy group) in 600ml toluene, add 0.6ml 37% concentrated hydrochloric acid, react at room temperature for 1 hour, add a large amount of deionized water to wash, and vacuum dry to obtain Hydroxylated butyl rubber; 99% conversion of epoxy groups to hydroxyl groups.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy rate | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com