Anchor hole construction technology

A construction process and bolt hole technology, which is applied in the installation of bolts, infrastructure engineering, construction, etc., can solve the problems of difficulty in forming holes, difficulty in drilling and constructing high-quality bolt holes, etc., to achieve rapid hole forming and improve drilling Efficient construction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

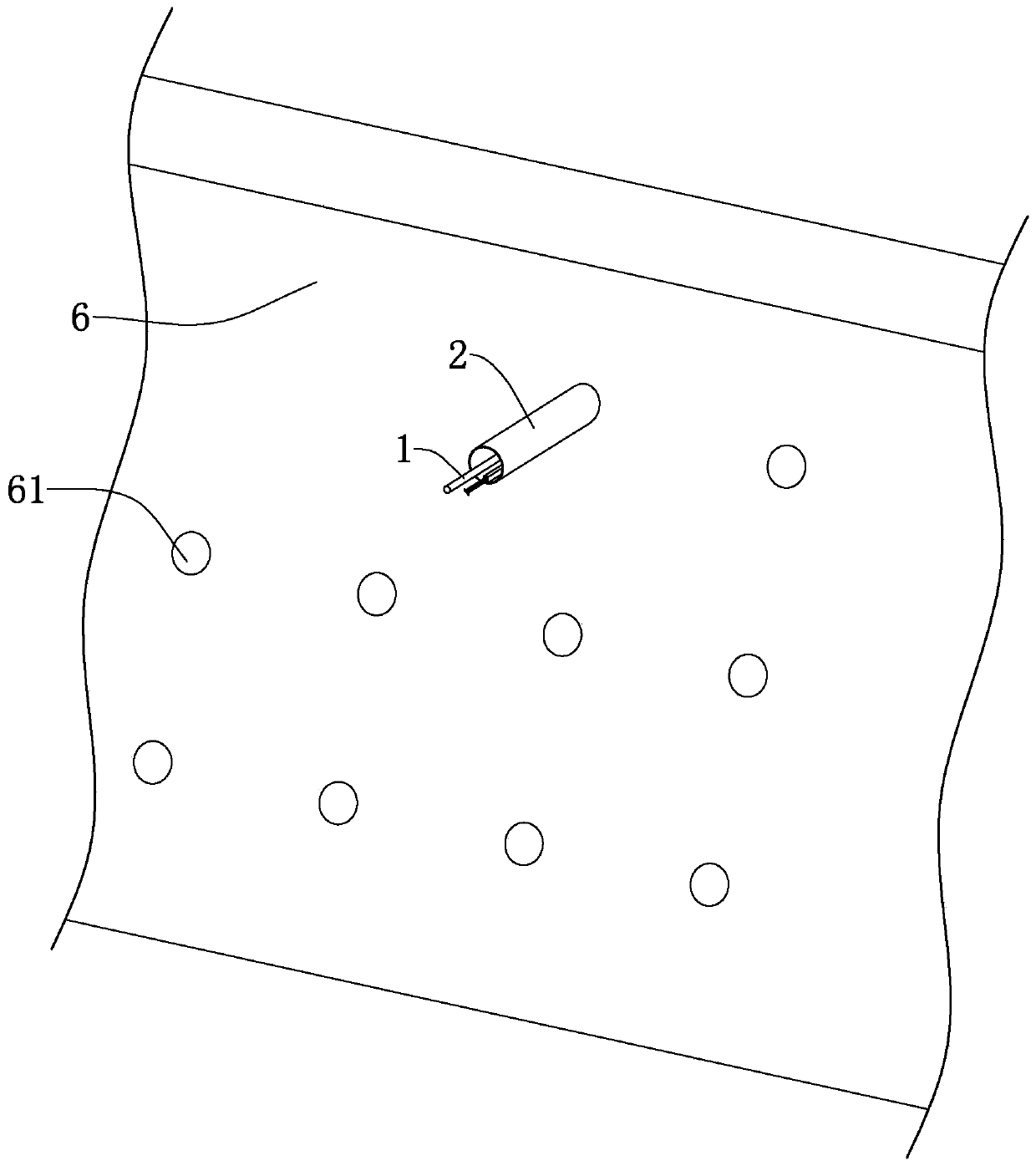

[0048] A bolt hole construction process, such as figure 1 As shown, the anchor rod hole 61 is drilled with a vibratory compaction hole forming device on the slope of the formation 6 that needs to be reinforced.

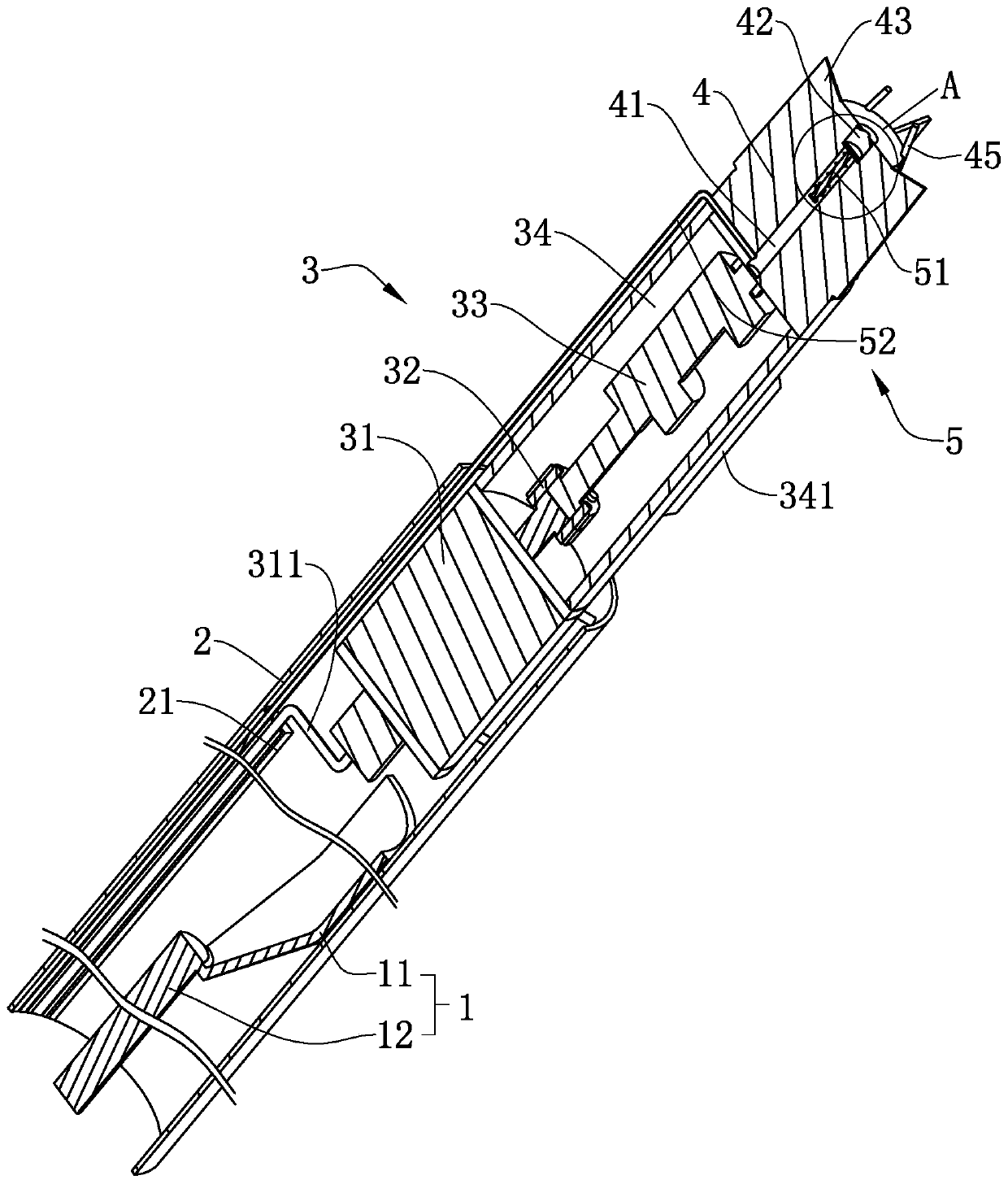

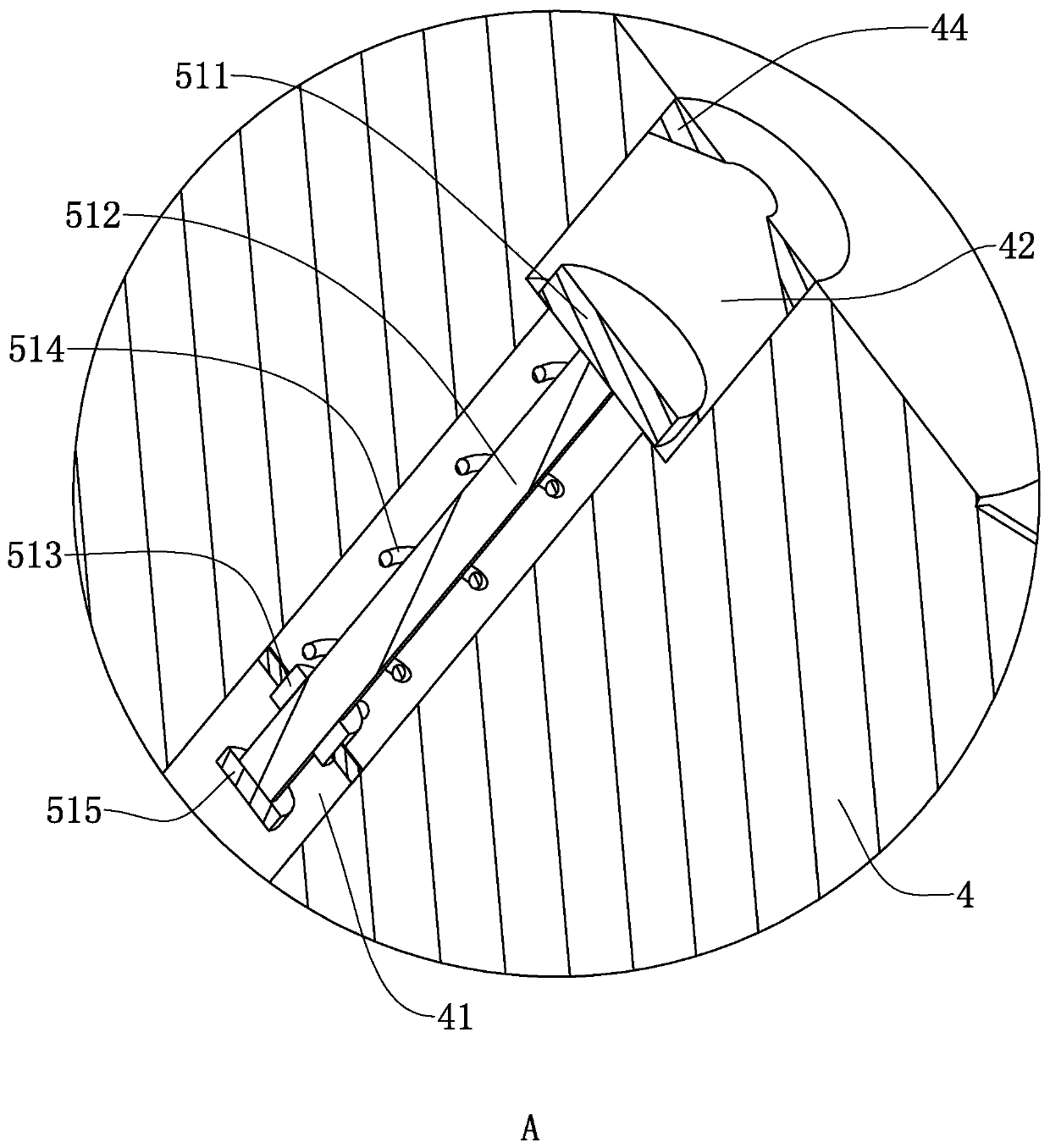

[0049] Such as figure 2 As shown, the vibrating compaction hole former includes a Luoyang shovel 1, which includes a U-shaped shovel body 11 and a long-rod shovel handle 12, and two adjacent shovel handles 12 are threaded. When the drilling depth of the anchor hole construction process is small, the number of 12 shovel handles is appropriately reduced to facilitate the use of Luoyang shovel 1 during drilling.

[0050] Such as figure 2 As shown, the casing 2 is sheathed on the outside of the shovel body 11, and the Luoyang shovel 1 slides along the side wall of the casing 2.

[0051] Such as figure 2 As shown, a plurality of connecting rods are welded and fixed at one end of the inner side of the casing 2, and a vibrator 3 is fixed on the connecting rods. The v...

Embodiment 2

[0070] A kind of bolt hole construction technique, differs from embodiment 2 in that, as Figure 4 As shown, the outer side of the sleeve 2 is covered with a positioning plate 7, on which the first horizontal bubble 71 parallel to the axis of the sleeve 2 is cemented and fixed, and on the positioning plate 7 is fixed a second horizontal bubble 71 perpendicular to the axis of the sleeve 2. Two levels of bubbles 72.

[0071] When determining the angle of the drill bit 4, set the positioning plate 7 on the outer side of the casing 2 near the end of the vibrator 3, and adjust the position of the casing 2 when drilling the anchor hole 61 with a horizontal axis using a vibration compacting hole forming device. , observe the horizontal bubble in the first horizontal bubble 71 at the same time, when the bubble in the first horizontal bubble 71 is in the middle, it can be confirmed that the position of the casing 2 is accurate; when drilling the bolt hole 61 with a vertical axis, obser...

Embodiment 3

[0073] A kind of bolt hole construction technique, differs from embodiment 2 in that, as Figure 5 As shown, the positioning plate 7 is provided with four relief holes 73 that are evenly distributed on the positioning plate 7 in the circumferential direction, and the axes of the relief holes 73 are parallel to the axis of the casing 2 . The positioning plate 7 is provided with a fixed frame 8, the fixed frame 8 includes a screw rod 82 passing through the relief hole 73, and the outer side of the screw rod 82 is welded on the positioning plate 7 for guiding the screw rod 82 to move along the axis of the casing 2 The limit tube 81, the end of the screw rod 82 away from the vibrator 3 is welded and fixed with a knob 83 whose diameter is larger than that of the relief hole 73.

[0074] After determining the position of the anchor hole 61, place the fixing frame 8 on the opening of the anchor hole 61, turn the screw rod 82 to insert the screw rod 82 into the formation 6, and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com