Automobile booster rubber tube

A technology for automotive superchargers and rubber hoses, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc. It can solve the problems of high cost, pressure difference, and low life, and meet strict requirements, reduce usage, The effect of reducing the amount of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings, however, the contents of the drawings and the specific implementation manner are not intended to limit the present invention.

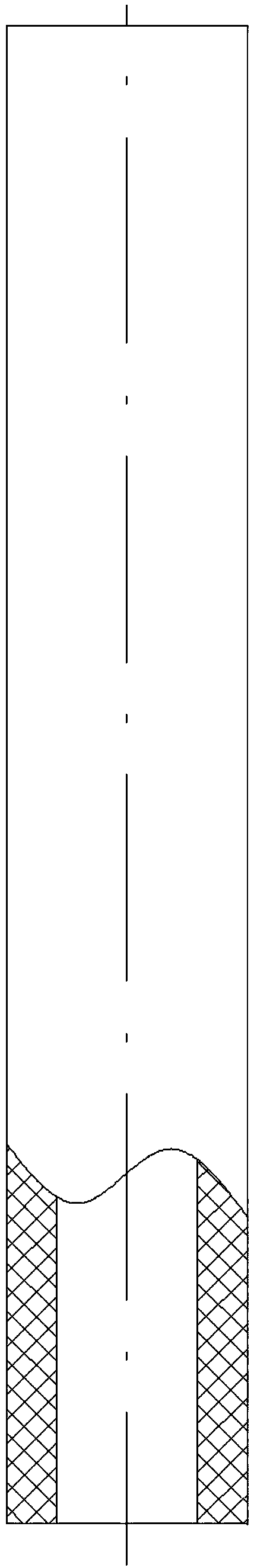

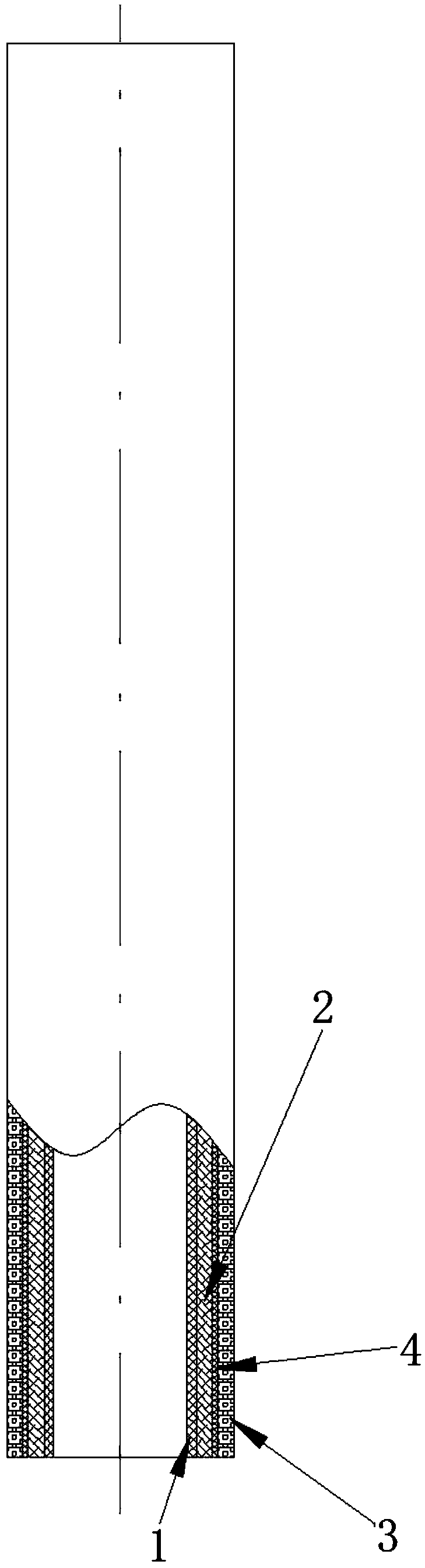

[0020] figure 2 A schematic structural view of the automobile supercharger rubber hose of the present invention is shown. Such as figure 2 As shown, unlike the existing automobile supercharger rubber hose which is made of pure fluorine rubber, the automobile supercharger rubber hose of the present invention has a multi-layer structure.

[0021] Specifically, the automobile supercharger rubber hose of the present invention includes an inner layer 1 . The inner layer 1 is made of fluorine rubber (FKM). Different from the 2.5-3.0mm thickness of the fluorine rubber layer in the conventional automobile supercharger rubber hose, in the present invention, the thickness of the inner layer 1 is only 0.6-0.8mm. In this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com