Lubricant smearing equipment used for auxiliary installation of heat collection pipes of solar water heater

A technology of solar water heaters and heat collecting tubes, which is applied in the direction of mechanical equipment, engine lubrication, engine components, etc., and can solve the problems of easily damaged heat collecting tubes, long time-consuming, uneven coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

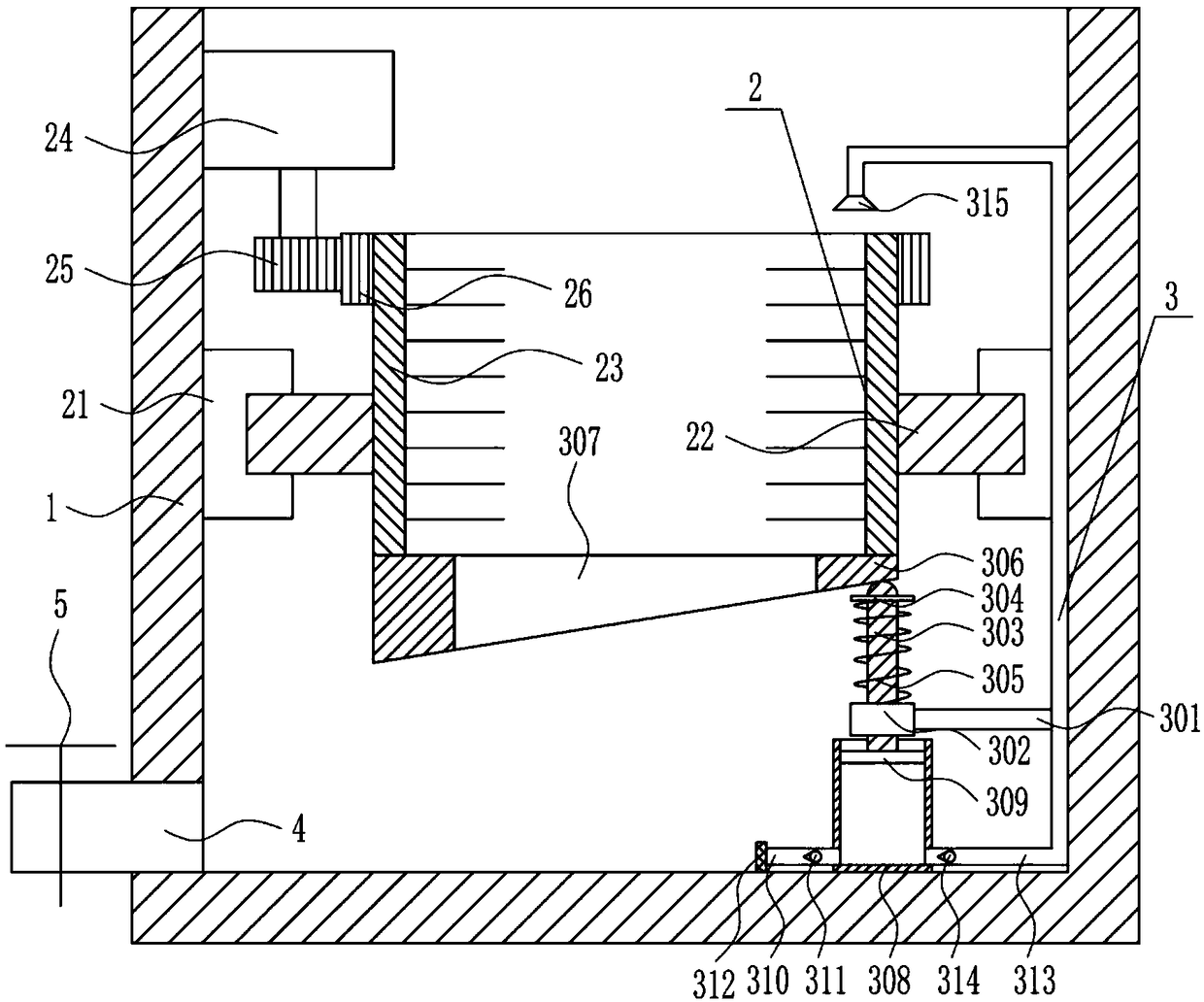

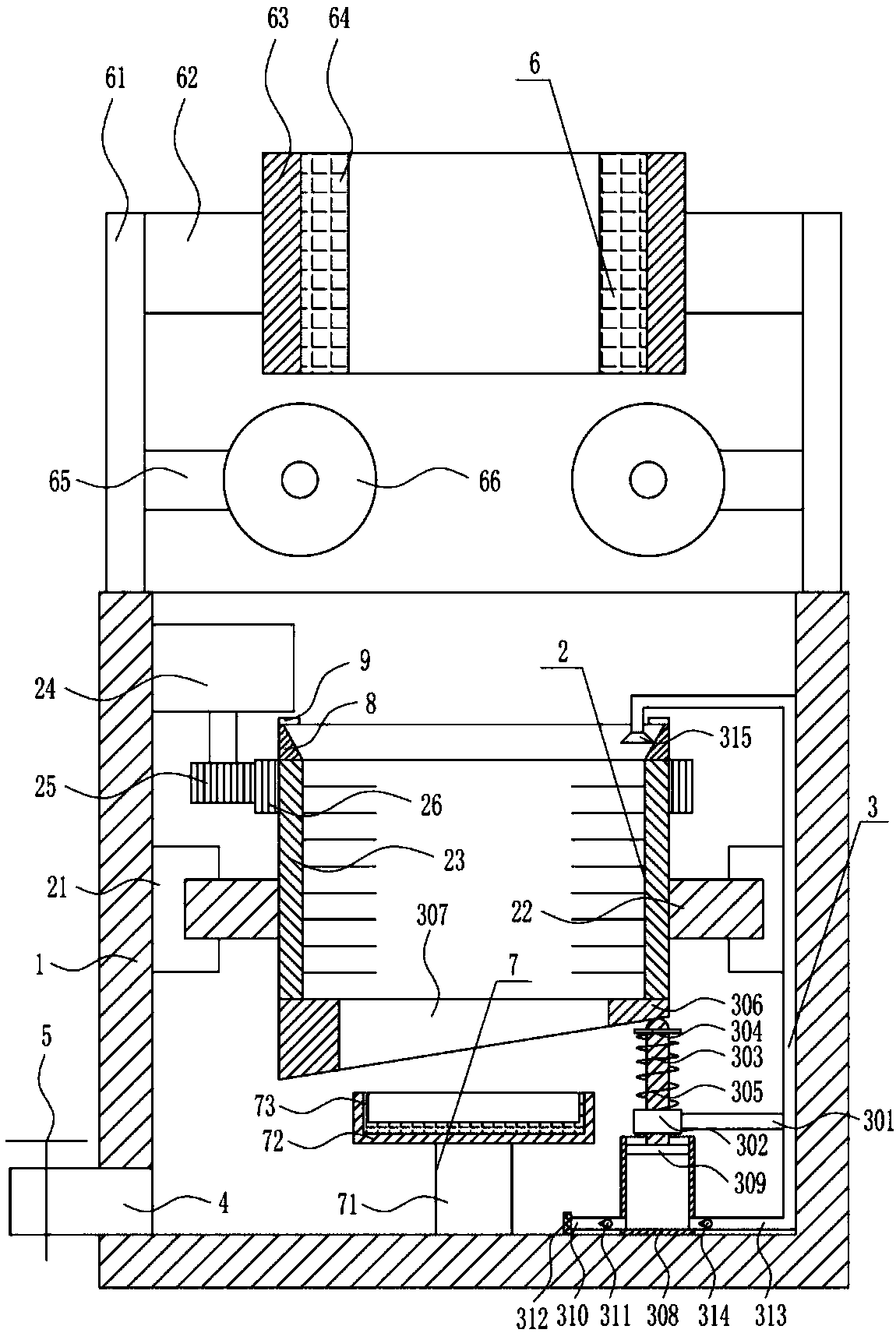

[0024] A kind of lubricating equipment for solar water heater collector tube auxiliary installation, such as Figure 1-2 As shown, it includes a treatment box 1, a smearing mechanism 2, a spraying mechanism 3, a water guide pipe 4 and a valve 5, a smearing mechanism 2 is installed on the inner wall of the treatment box 1, a spraying mechanism 3 is installed on the treatment box 1, and the left side of the treatment box 1 The bottom is connected with an aqueduct 4, and the aqueduct 4 is provided with a valve 5.

Embodiment 2

[0026]A kind of lubricating equipment for solar water heater collector tube auxiliary installation, such as Figure 1-2 As shown, it includes a treatment box 1, a smearing mechanism 2, a spraying mechanism 3, a water guide pipe 4 and a valve 5, a smearing mechanism 2 is installed on the inner wall of the treatment box 1, a spraying mechanism 3 is installed on the treatment box 1, and the left side of the treatment box 1 The bottom is connected with an aqueduct 4, and the aqueduct 4 is provided with a valve 5.

[0027] The smearing mechanism 2 includes an annular slide rail 21, a slide block 22, an annular brush plate 23, a motor 24, a gear 25 and an annular rack 26, and the middle part of the inner wall of the processing box 1 is provided with an annular slide rail 21, on which the annular slide rail 21 slides. The formula is provided with a plurality of sliders 22, an annular brush plate 23 is connected between the sliders 22, a motor 24 is installed on the top of the inner l...

Embodiment 3

[0029] A kind of lubricating equipment for solar water heater collector tube auxiliary installation, such as Figure 1-2 As shown, it includes a treatment box 1, a smearing mechanism 2, a spraying mechanism 3, a water guide pipe 4 and a valve 5, a smearing mechanism 2 is installed on the inner wall of the treatment box 1, a spraying mechanism 3 is installed on the treatment box 1, and the left side of the treatment box 1 The bottom is connected with an aqueduct 4, and the aqueduct 4 is provided with a valve 5.

[0030] The smearing mechanism 2 includes an annular slide rail 21, a slide block 22, an annular brush plate 23, a motor 24, a gear 25 and an annular rack 26, and the middle part of the inner wall of the processing box 1 is provided with an annular slide rail 21, on which the annular slide rail 21 slides. The formula is provided with a plurality of sliders 22, an annular brush plate 23 is connected between the sliders 22, a motor 24 is installed on the top of the inner ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap