Steam generator blowdown apparatus

A steam generator and sewage device technology, applied in the chemical industry, can solve the problems of continuous impact on the bottom of the sewage pipe, uneven distribution, inability to inhale and discharge sewage, or even accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

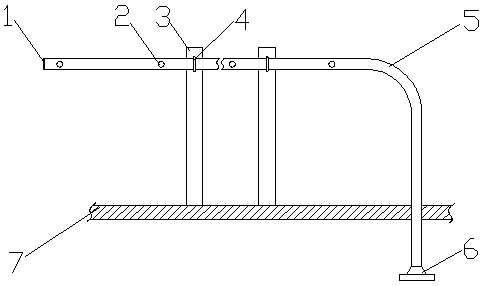

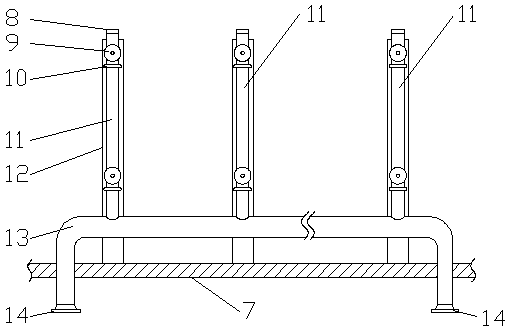

[0037] This embodiment provides a blowdown device for a steam generator, which consists of a main blowdown pipe 13, a number of secondary blowdown pipes 11, and a number of suction heads 9 arranged on each secondary blowdown pipe 11, the number of secondary blowdown pipes 11 and The number of sewage suction heads 9 on each auxiliary sewage pipe 11 is determined by the liquid level in the steam generator; for the convenience of description, the following descriptions use a main sewage pipe 13 to connect three auxiliary sewage pipes 11, each auxiliary sewage pipe There are two dirt suction heads 9 on 11 for description. Such as image 3 As shown, three secondary sewage pipes 11 are connected in parallel on a main sewage pipe 13, and the diameter of the secondary sewage pipes 11 is slightly smaller than the diameter of the main sewage pipe 13, so that the sewage collected by the secondary sewage pipes 11 has sufficient space in the main sewage pipe 13. Flow space; the distance b...

Embodiment approach 2

[0042] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, sewage will be diverted when it enters the sewage suction chamber 20 through the sewage suction narrow channel 19, and a small part of it will flow along the sewage suction chamber 20. The wall flows down, and most of them flow down vertically through the sewage suction narrow channel 19 and impact the bottom of the sewage suction chamber 20, and impact the lower pipe wall of the auxiliary sewage pipe 11 at a relatively high speed, which greatly affects the life of the auxiliary sewage pipe 11; In this way, the above-mentioned defects can be effectively avoided.

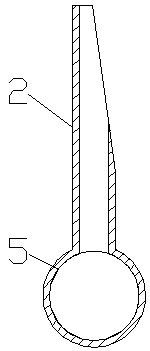

[0043] Specifically, in the sewage discharge device of the steam generator in this embodiment, the sewage suction head 9 also includes a blocking cap 21 structure, and the structure of the blocking cap 21 is as follows: Figure 9~11 As shown, the upper part is an arc-shaped housing 16 extending into the dirt...

Embodiment approach 3

[0047] This embodiment is a further improvement of Embodiment 2. The main improvement is that in Embodiment 2, the arc-shaped outer wall of the auxiliary sewage pipe 11 is in line contact with the plane of the T-shaped steel 12, and the pressure is relatively high, which is easy to cause The device is unstable, and the height difference between the auxiliary sewage pipe 11 and the main sewage pipe 13 due to the different diameters will also affect the stability of the device. In this embodiment, however, the above defects can be effectively avoided.

[0048] Specifically, in this embodiment, a saddle-shaped block 26 is placed between the auxiliary sewage pipe 11 and the T-shaped steel, and inside the U-shaped bolt 10, as Figure 12 with 13 , the lower surface of the saddle block 26 is a plane in contact with the T-shaped steel 12, and the upper surface is a concave arc surface that fits the lower part of the auxiliary sewage pipe 11. On the one hand, the saddle block 26 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com