Efficient low-temperature instant freezer, and shrimp product instant freezing processing technology applying same

A quick-freezing machine and low-temperature technology, which is applied in the field of quick-freezing technology, can solve the problems of increased production costs, long quick-freezing time, and high power consumption, and achieve the effects of reducing power consumption, energy consumption, and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

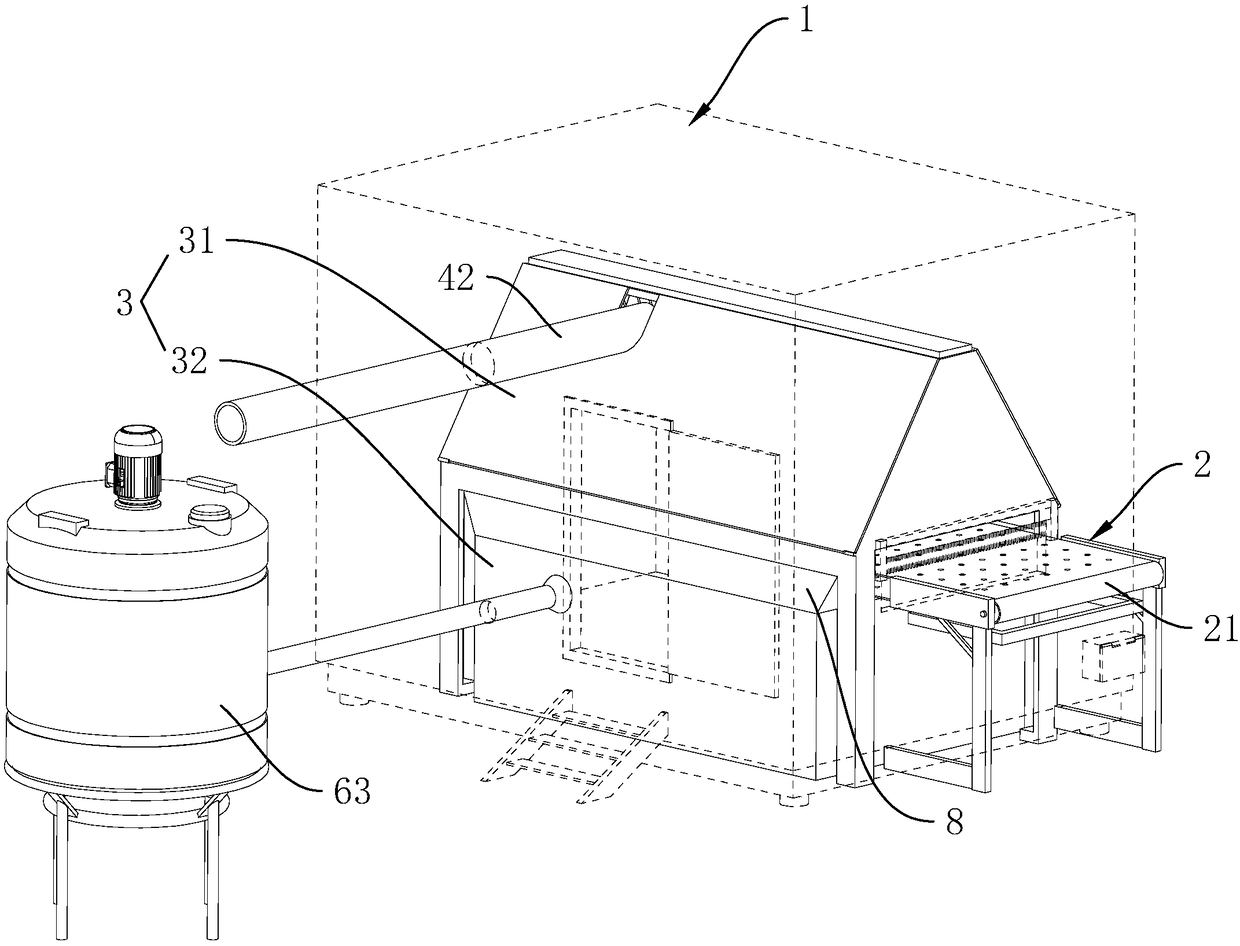

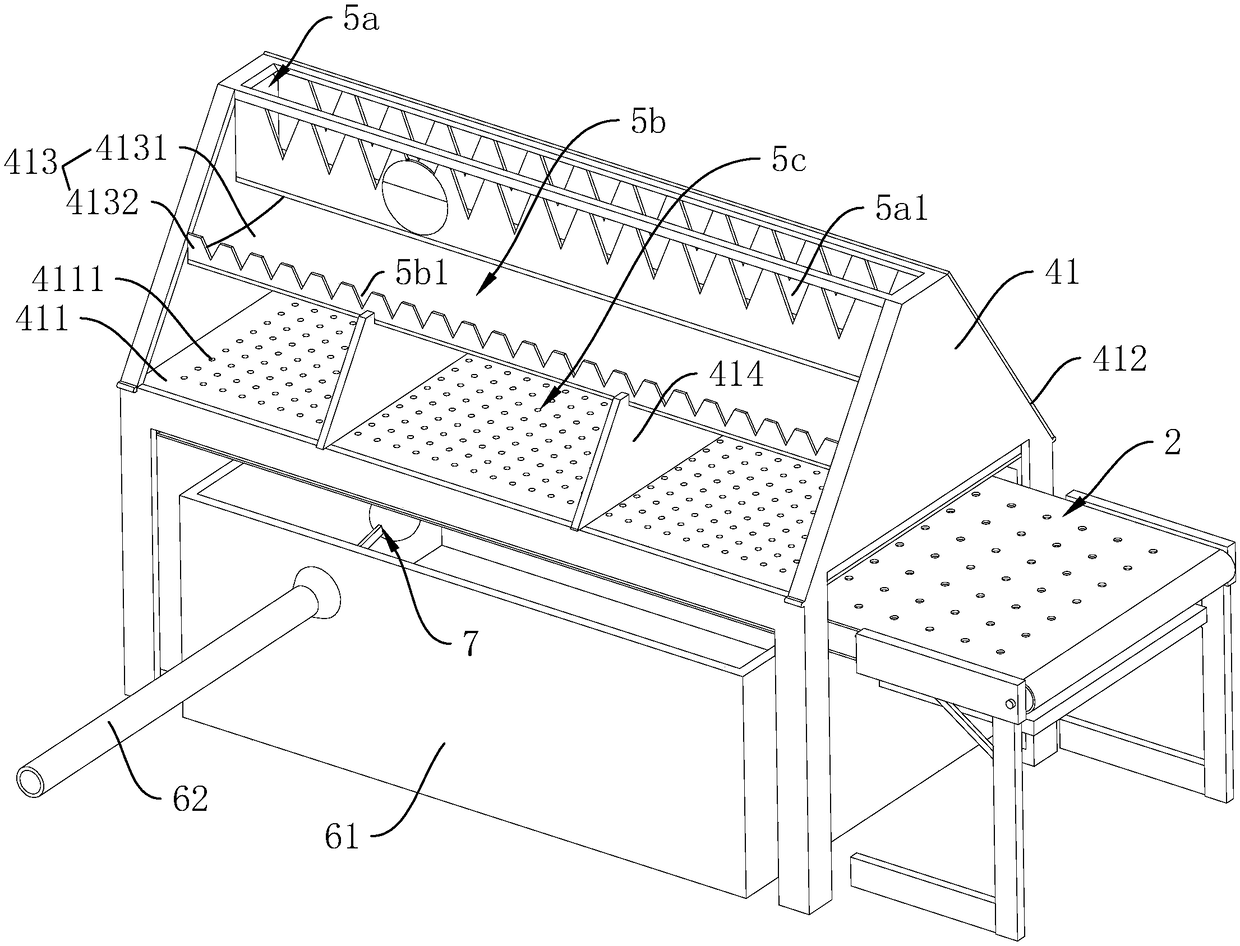

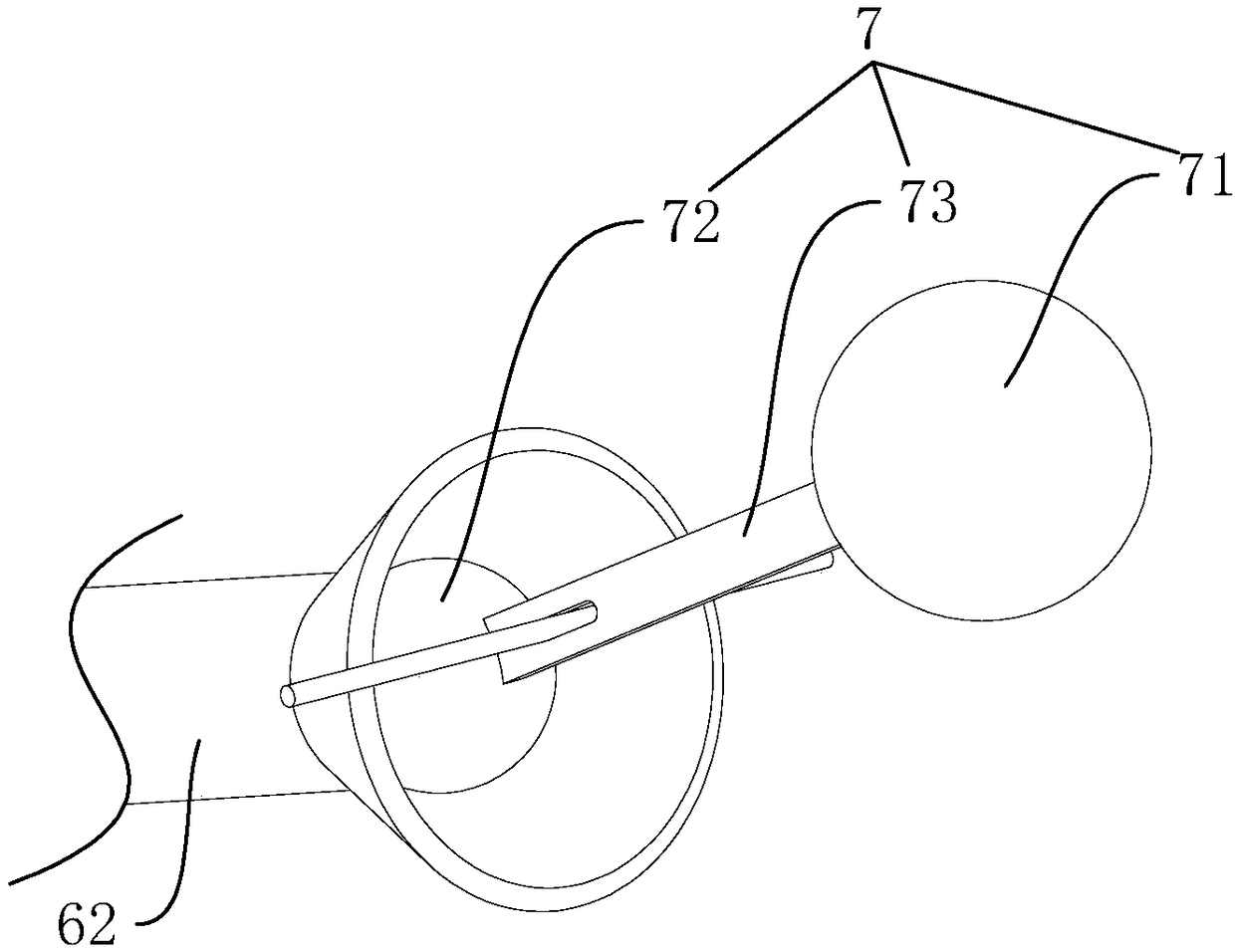

[0031] Such as figure 1 and figure 2 As shown, a high-efficiency low-temperature quick-freezing machine includes an externally placed thermal insulation storage body 1, and the thermal insulation storage body 1 is assembled with polyurethane sandwich double-sided stainless steel plates. The main part of the heat exchange system 3 is installed in the heat preservation storehouse body 1, and the heat exchange system 3 includes an air supply device 31 for providing strong cold air in a vertical downward direction and a refrigeration device 32 for absorbing hot air in the heat preservation storehouse body 1. The device 32 is mainly arranged directly below the air supply device 31, and a quick-freezing chamber is formed in the thermal insulation storehouse body 1 between the two; Based on the conveying mesh belt 21 for conveying frozen products and the power source for driving the conveying mesh belt 21, the thermal insulation storage body 1 has a feed inlet and a discharge port ...

Embodiment 2

[0042] A quick-freezing process for shrimp products, using the quick-freezing machine described in Example 1, the whole process is carried out in a thawing chamber, and the temperature of the thawing chamber is controlled at 20°C, specifically comprising the following steps:

[0043] S1, defrosting raw shrimp;

[0044] Thaw the purchased frozen raw shrimp, specifically soak the raw shrimp in a thawing tank with a cold water temperature of 15°C, and thaw for at least 8 hours to reduce the contact between the shrimp body and oxygen in the air, control the temperature, and weaken the molecular heat Exercise, thereby reducing the efficiency of oxidation, choose the evening time, and reasonably allocate the time in the processing cycle. After thawing, the quality and sanitation inspection of the shrimp body is carried out, and the unqualified shrimp body is discarded.

[0045] S2, cleaning and sorting;

[0046] Arrange manpower to lay the shrimp body on the conveyor belt connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com