Intelligent artistic design product brushing pigment drying and dedusting device

A technology of dust removal device and design product, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of slow efficiency and affecting the quality of pigments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

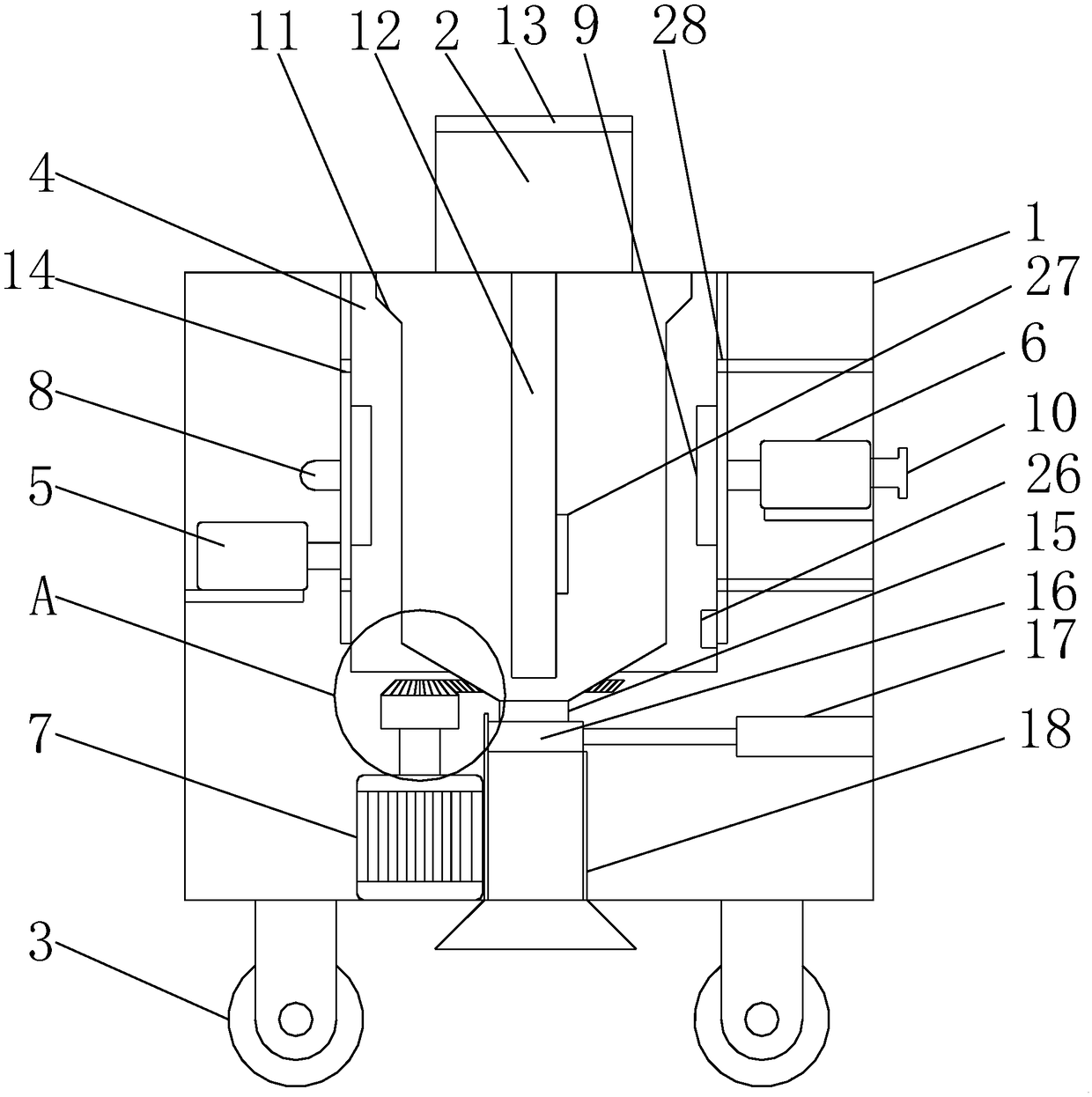

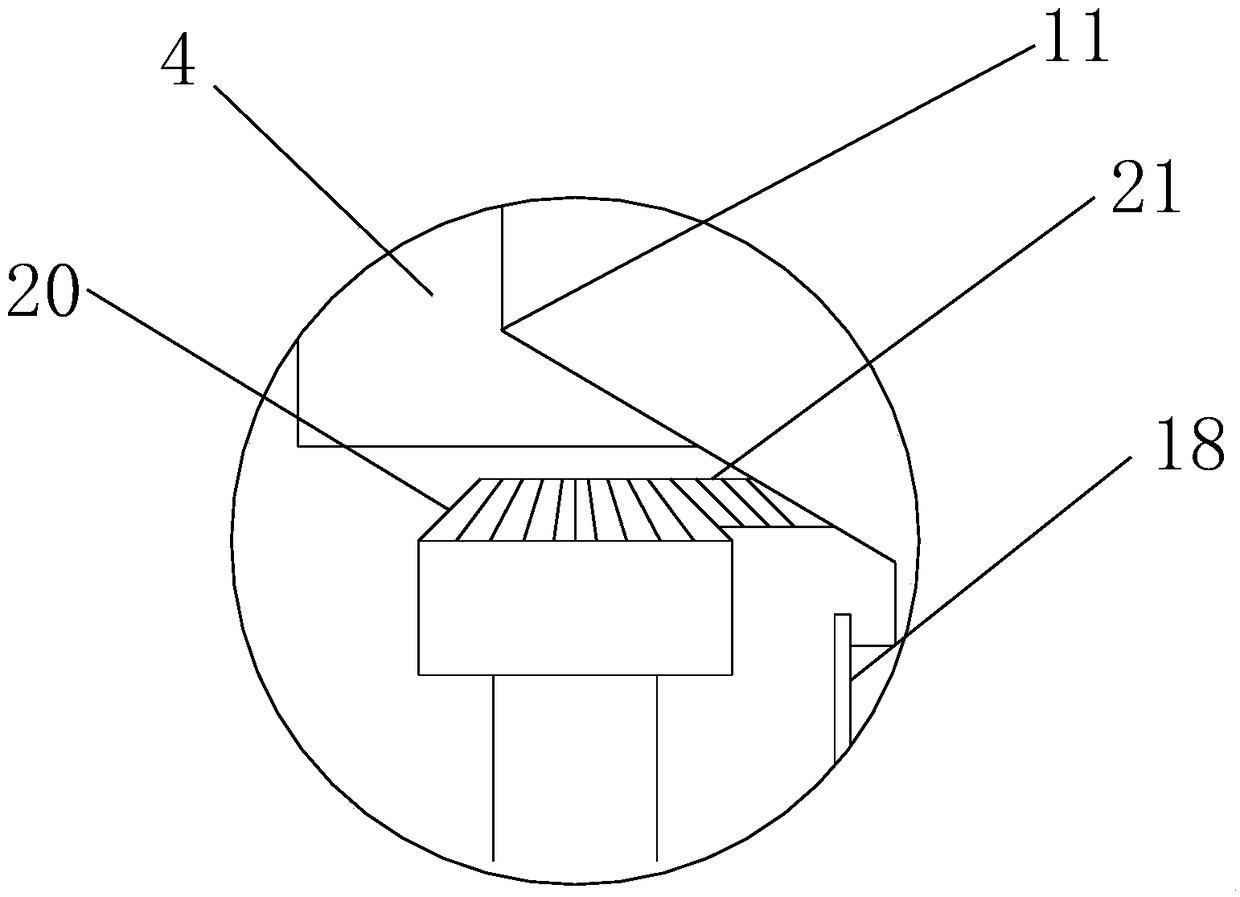

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same components. In order to keep the drawings concise, each drawing only schematically shows the parts related to the invention, and they do not represent the actual structure of the product.

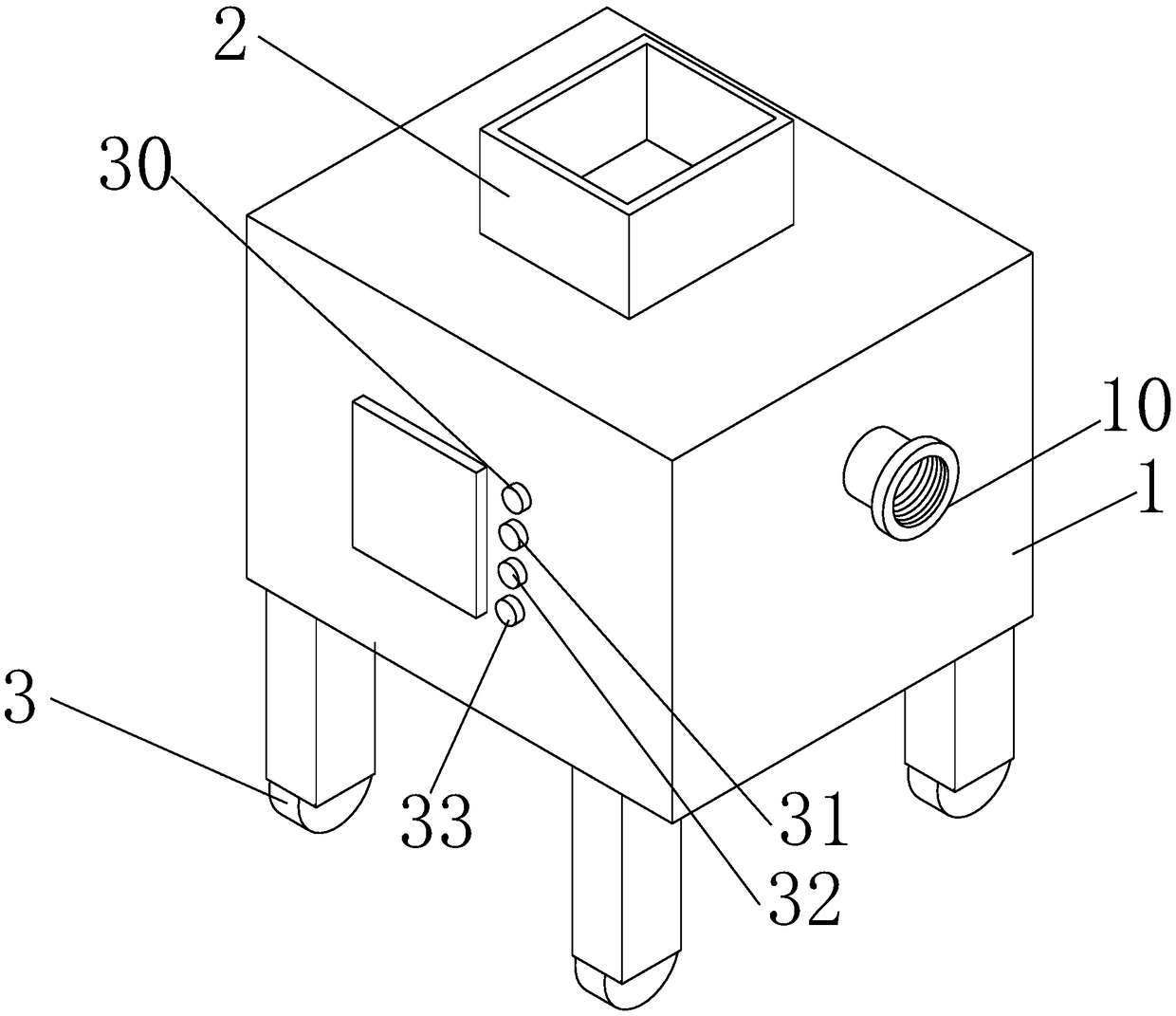

[0025] Such as figure 1 , 2 , 3, 4, 5, and 6, the present invention is a drying and dedusting device for painting and coloring materials of intelligent artistic design products. , the discharge pipeline 18 located at the bottom of the box body 1 and the control system located on the outer surface of the box body 1; the color material enters from the feed port 2 and is discharged from the discharge pipeline 18, and can be better grasped by setting the control system The drying temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com