Efficient and energy-saving defogging cooling tower and defogging method thereof

A high-efficiency energy-saving cooling tower technology, applied in the field of cooling towers, can solve the problems of reducing the temperature of saturated hot and humid air, reducing the moisture content of saturated hot and humid air, cooling tower cooling and defogging effects are not ideal, and achieve load reduction and mixed condensation Enhanced effect and ease of equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

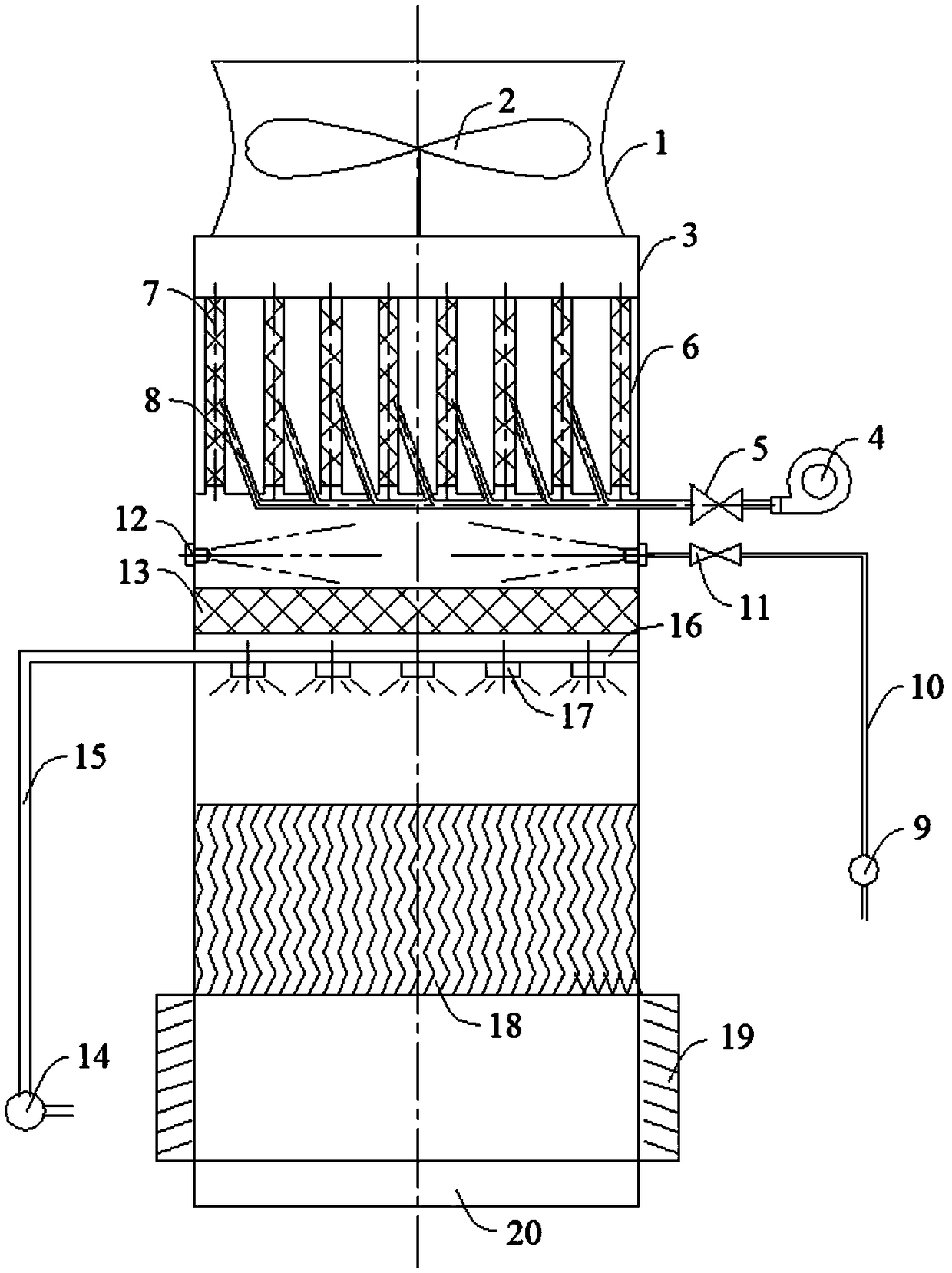

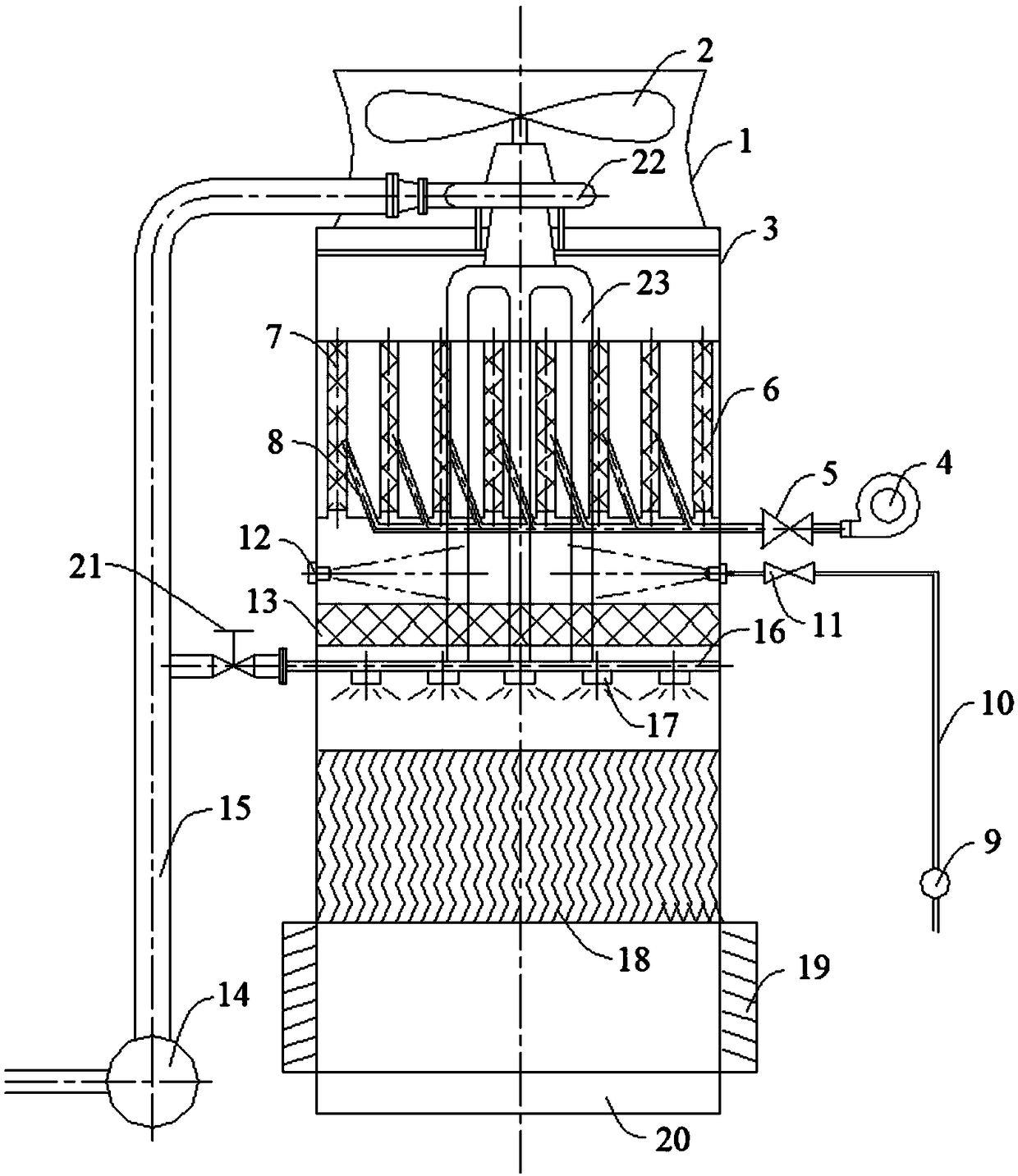

[0043] combine figure 1 , a high-efficiency energy-saving defogging cooling tower of the present embodiment is provided with an air duct 1 at the top of the tower body 3, and an axial flow fan 2 is arranged in the middle of the air duct 1, and the axial flow fan 2 is driven by a motor accelerator and decelerator to run, and then Make the axial flow fan 2 work; in the middle of the tower body 3, the air mixing condensing chamber 6, atomizing nozzle 12, water collector 13, water distributor 16 and cooling packing 18 are arranged sequentially from top to bottom; the bottom of the tower body 3 An air inlet 19 and a sump 20 are provided, and the air inlet 19 is arranged on the side wall of the cooling tower body 3 above the sump 20 .

[0044] A water pump 14 is arranged outside the cooling tower, and the water pump 14 sends hot water to the water distributor 16 in the cooling tower through the hot water inlet pipe 15, and the hot water is sprayed by the water distributor nozzle 17 ...

Embodiment 2

[0051] The high-efficiency energy-saving defogging cooling tower of this embodiment is basically the same as that of Embodiment 1, except that one valve 11 of this embodiment controls two atomizing nozzles 12 at the same time.

Embodiment 3

[0053] A high-efficiency energy-saving defogging cooling tower of this embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the mixed air condensation channel 7 and the air introduction channel 8 are connected into an assembly, and the assembly is connected to the tower The side walls of the body 3 are connected to each other, which is a detachable structure. In actual use, the assembly body can be easily installed in the cooling tower without a large degree of modification to the cooling tower; at the same time, due to the long-term use of the cooling tower , The inside of the mixed air condensation channel 7 is prone to fouling and needs to be cleaned regularly. It is designed as a detachable structure and is more convenient for equipment maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com