Floor wax detection device

A testing equipment, floor wax technology, applied in the direction of measuring devices, testing wear resistance, instruments, etc., can solve the problems of mold, matte loss, low hardness of wooden floors, etc., to achieve high detection accuracy, controllable detection process, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

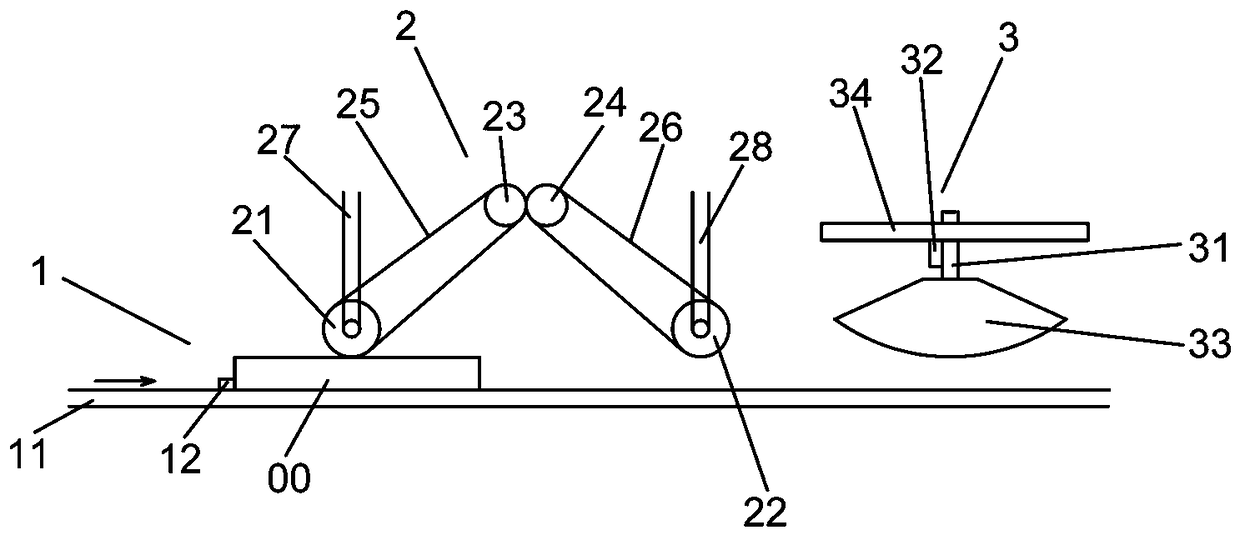

[0025] Example one: such as figure 1 Shown is only one of the embodiments of the present invention. A floor wax detection device includes a conveyor 1, a pressing device 2 and an induction device 3. The conveyor 1 includes a conveyor belt 11 and is arranged on the conveyor belt 11 The limit block 12, the squeezing device 2 includes a first squeeze roller 21, a second squeeze roller 22, a first drive roller 23 and a second drive roller 24, the first squeeze roller 21 passes through the first The traction belt 25 is connected to the first drive roller 23, and the second squeeze roller 22 is connected to the second drive roller 24 through a second belt 26, the first drive roller 23 and the second drive roller 24 In engagement with each other, the sensing device 3 includes a movable plate 31 and a fixed plate 32, the end of the movable plate 31 is provided with an induction head 33, and the fixed plate 32 is electrically connected with a circuit board 34.

[0026] In order to test t...

Embodiment 2

[0031] Example two, still as figure 1 As shown, it is still one of the embodiments of the present invention. In order to make the floor wax detection equipment of the present invention more practical and stable, with high detection accuracy, the present invention also has the following designs:

[0032] First add on the conveyor 1:

[0033] Since the floor to be tested 00 will be subjected to friction in two opposite directions, in order to better facilitate the transmission of the floor to be tested 00, at least one limit block 12 must be set at the front and the rear of the transmission direction of the floor to be tested 00. In addition, a plurality of floors 00 to be tested can be simultaneously conveyed on the conveyor belt 11 to perform a simulated squeeze friction test in turn, so there are at least multiple sets of limit blocks 12, so the number of limit blocks 12 is at least one.

[0034] Then the addition of squeeze device 2:

[0035] In order to better simulate the scratch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com