Laser breakdown spectra measuring system based on beam shaping

A laser breakdown spectrum and beam shaping technology, applied in the field of laser breakdown spectrum measurement system, can solve the problem of energy difference between the center and edge of the plasma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

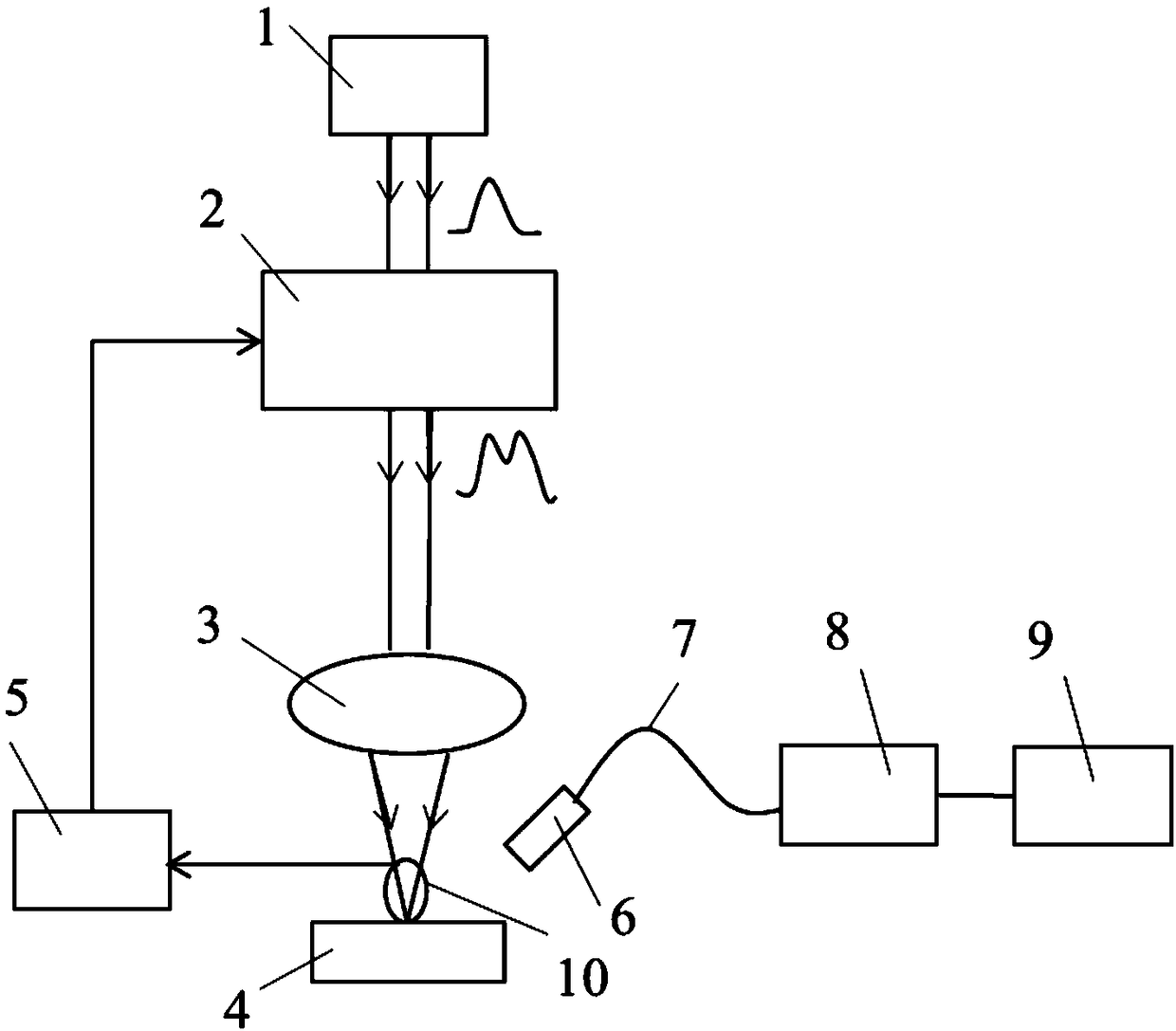

Method used

Image

Examples

Embodiment 1

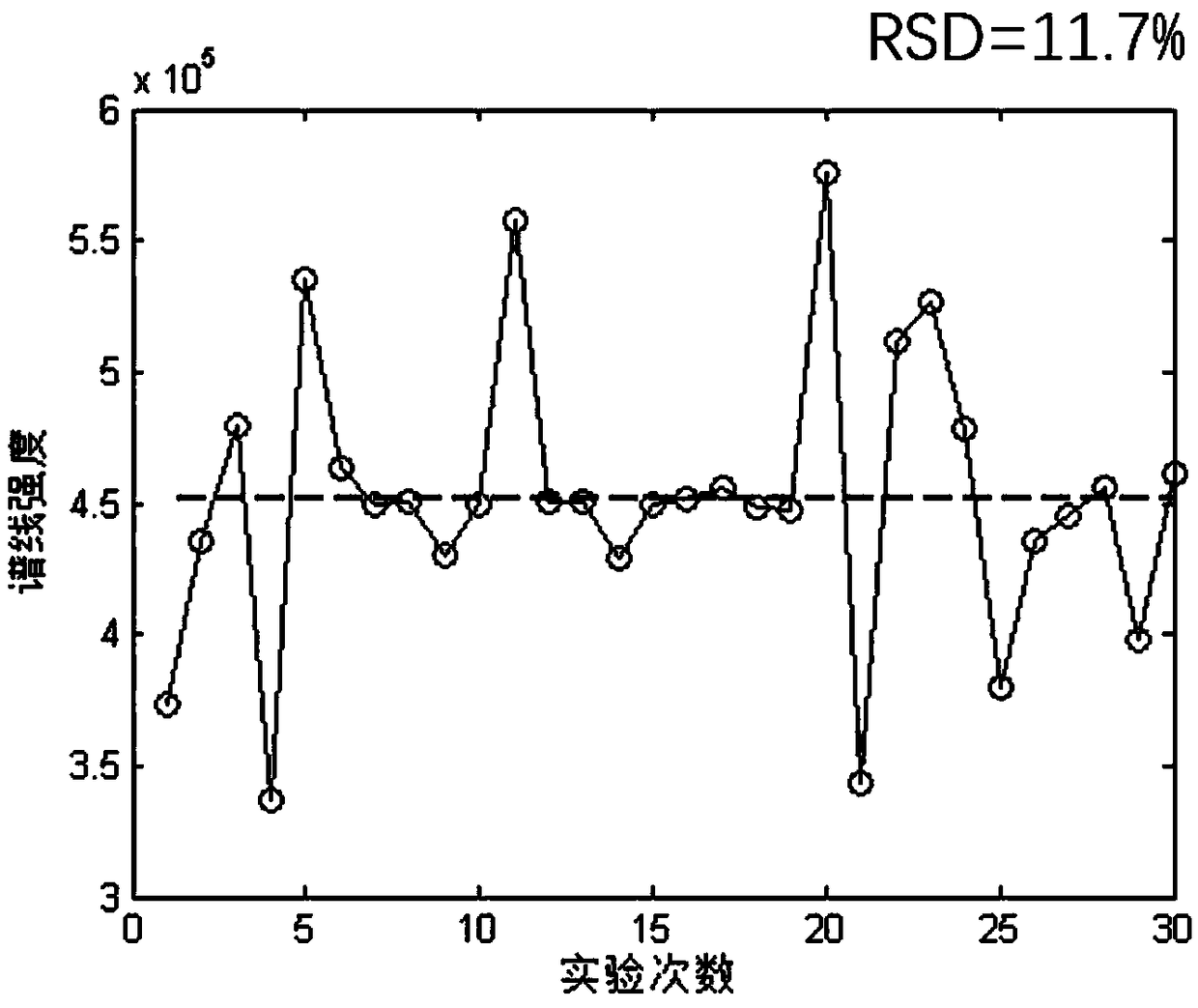

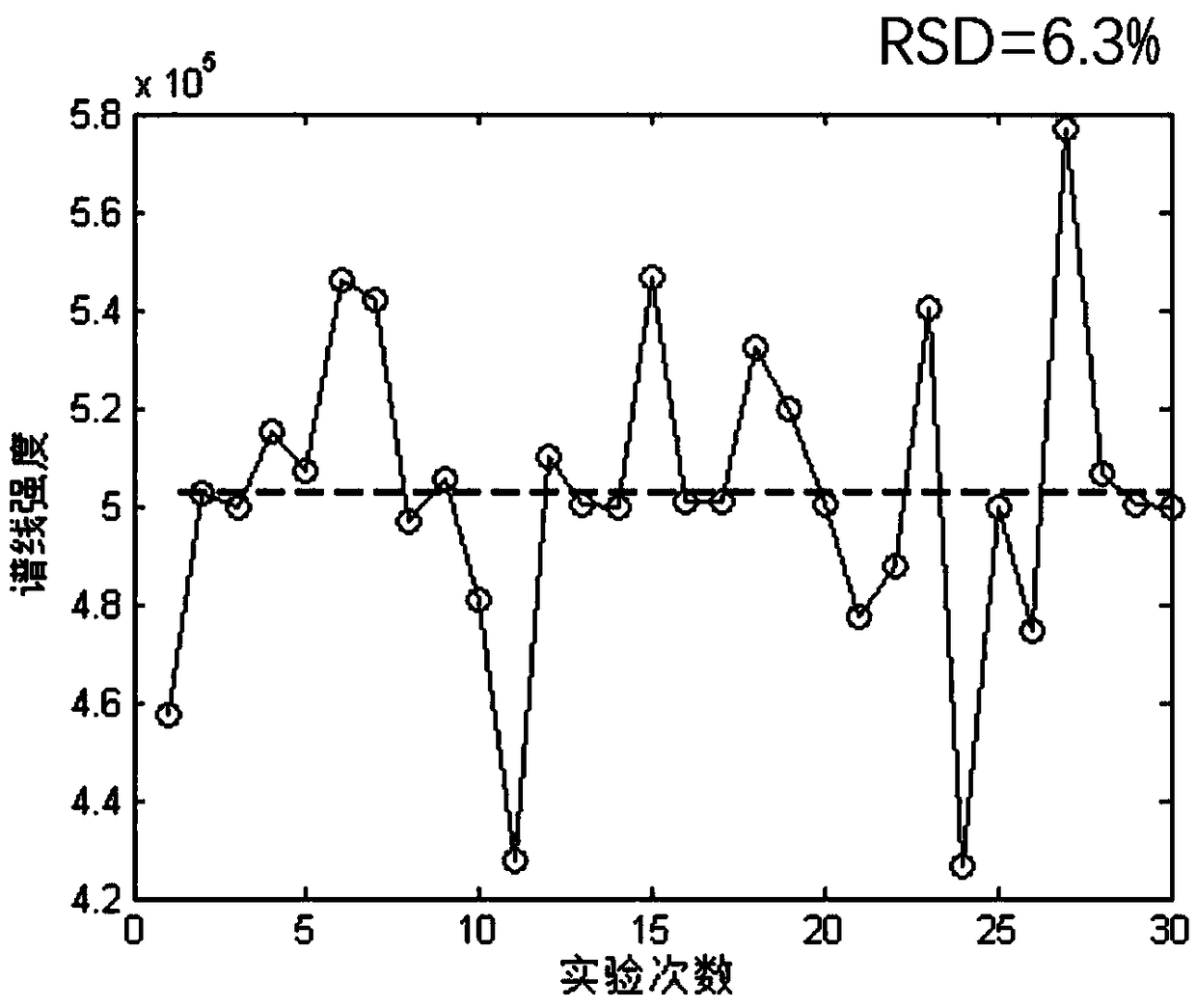

[0019] Taking the aluminum alloy sample as an example, the LIBS experiment is carried out on the aluminum alloy sample. The pulse laser used in the experiment is an ND:YAG solid-state laser with a laser wavelength of 1064nm. The pulse laser can emit pulse laser. The total energy of each pulse laser is 50mJ. The pulse width of the pulse is 10 ns. The laser spot before shaping is circular, and the energy density is higher at the center of the spot and lower at the edge. The programmable beam shaper changes the shape of the laser beam profile from a Gaussian distribution to the following distribution: the shape of the shaped laser profile is still circular, the center of the profile has almost the same energy density, and the laser energy at the edge is slightly higher than the center. Focus the laser on the surface of the sample and ablate the sample, generate plasma and analyze the spectral lines.

[0020] In this case, under the conditions of not using the beam shaper and usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com