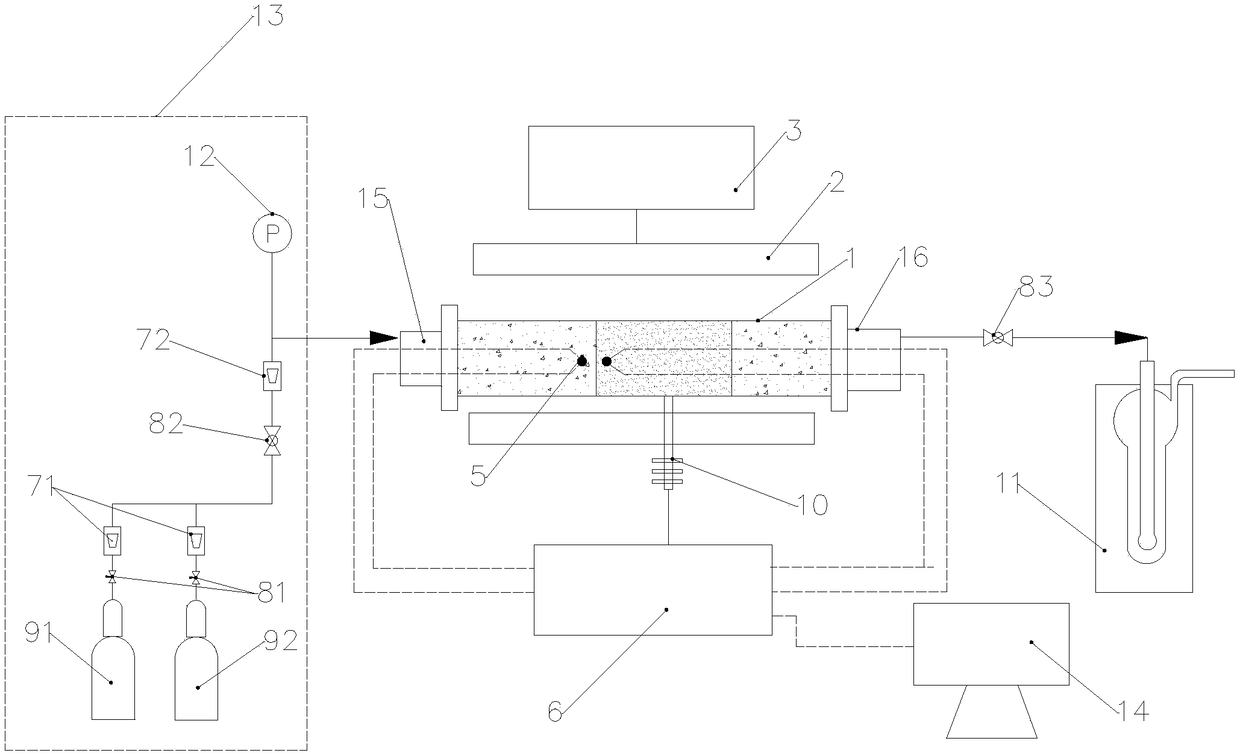

Porous medium reaction heat effect monitoring device and method

A technology of porous media and monitoring devices, applied in the direction of material thermal development, etc., can solve the problems of unfavorable catalyst evaluation, affecting oxidation/combustion reaction and catalyst catalytic activity, and achieve the effect of increasing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

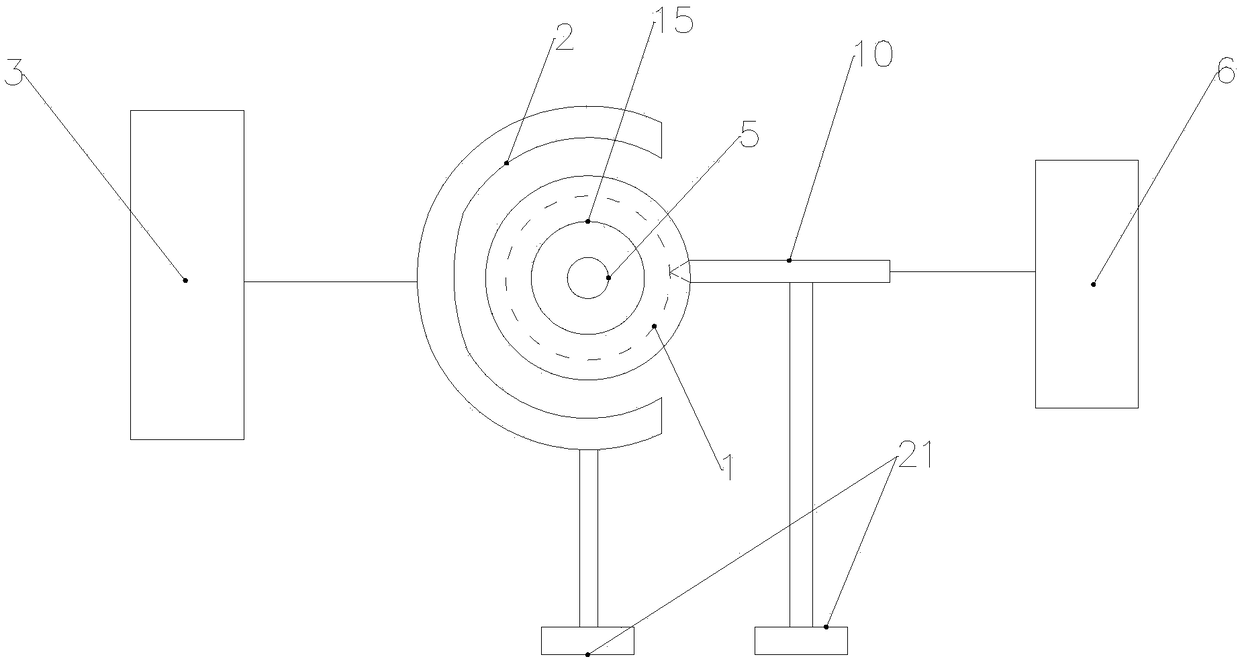

Method used

Image

Examples

Embodiment

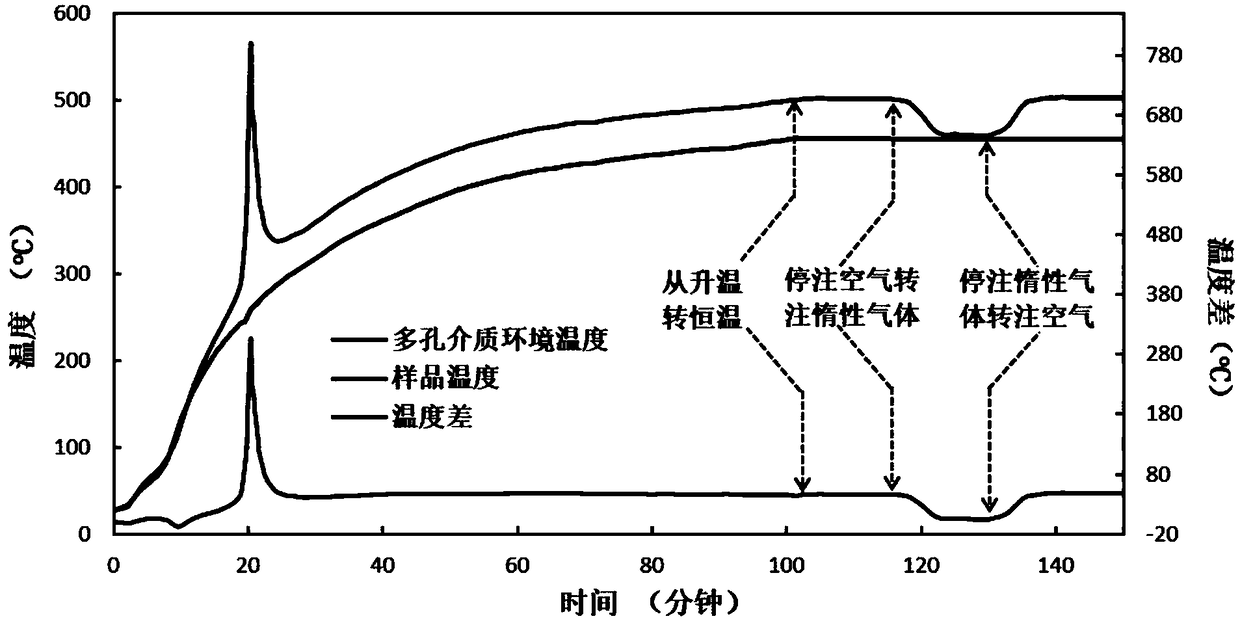

[0052] Before the experiment, crude oil and quartz sand were mixed evenly at a mass ratio of 1:4. According to the above-mentioned experimental method, the transparent quartz reactor 1 was filled and a differential thermocouple 5 was placed, the filling length of the reaction sample was 5 cm, and the temperature-rising oxidation experiment was carried out at an air flow rate of 1 L / min. After the transparent quartz reactor 1 is continuously heated to 455°C, stop heating up, keep the transparent quartz reactor at a constant temperature of 455°C, and close the control valve 1 81 and the gas flow meter 71 above the high-pressure air bottle 91 at 115 minutes, and open the high-pressure Control valve one 81 and gas flowmeter 71 above the helium gas cylinder 92, monitor the temperature of the two differential thermocouples 5 on the computer, when it is found that the temperature difference between the two differential thermocouples 5 gradually decreases, and the temperature of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com