Compound co-extrusion board with light guide and diffusion functions, and manufacturing method thereof

A technology of light diffusing agent and function, applied in the field of composite co-extruded sheet and its preparation, can solve the problems of affecting the light passing efficiency, affecting the working efficiency, complex process, etc., so as to improve the production and processing efficiency, reduce the assembly process and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

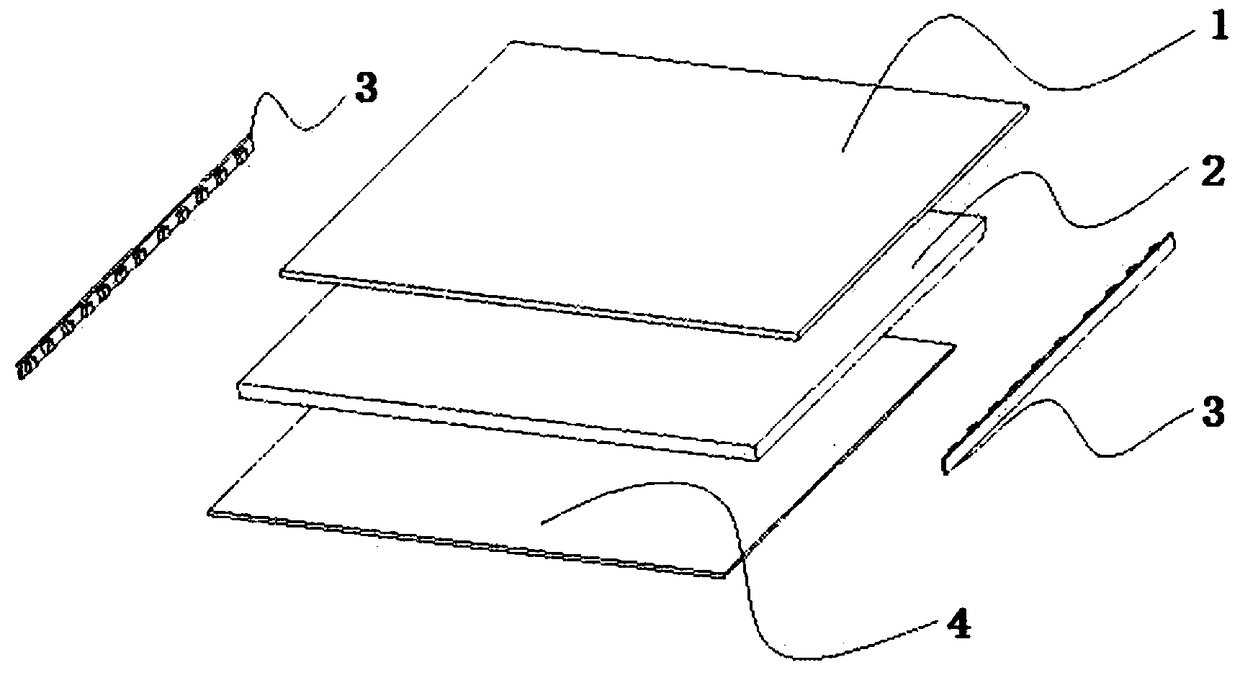

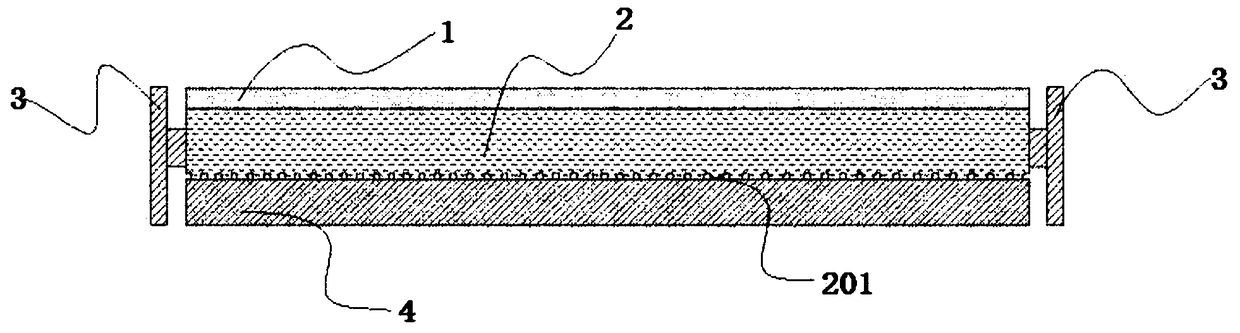

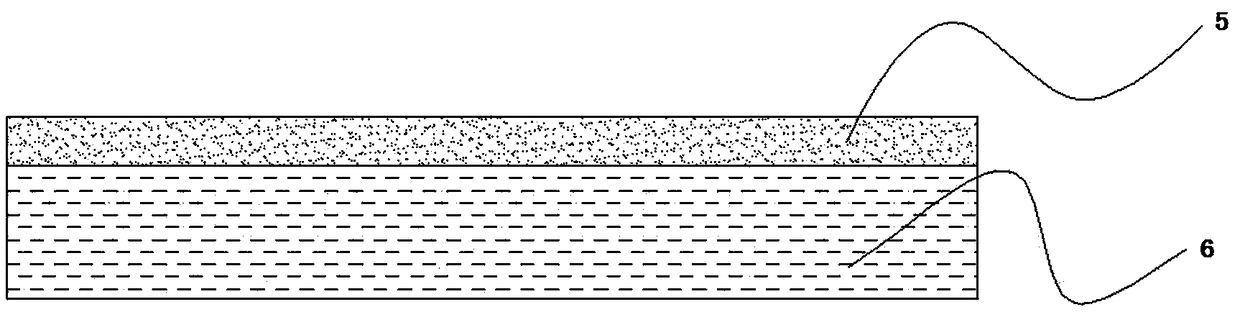

[0029] like image 3 As shown, it shows a kind of composite co-extrusion plate with light guide and diffusion function of the present invention, comprising PMMA light guide layer 6 and PMMA diffusion layer 5, PMMA light guide layer 6 is extruded by extrusion process by PMMA raw material A transparent thin plate, the thickness of the PMMA light guide layer 6 is 2.0-3.0mm, and the PMMA diffusion layer 5 is composed of the following components according to mass percentage: 86%-98.59% of polymethyl methacrylate, 0.01%-7% of light diffusing agent, 0.1%~1.5% of heat stabilizer, 0.1%~1.5% of light stabilizer, 0.1%~1.5% of processing aid, PMMA diffusion layer 5 is the material particle of PMMA and light diffusion agent, heat stabilizer, light stabilizer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com