Method for recovering toner powder in a dry manner

A carbon-recovery, dry-type technology, applied in the fields of electrography, optics, instruments, etc., can solve the problems of cumbersome operation and complicated mechanical settings, and achieve the effect of improving the washing effect, good fusion, and exquisite settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for dry recycling carbon powder, comprising the steps of:

[0064] Step 1. First, classify the toner cartridges according to the information of the sensor chip of the toner cartridge, and classify the toner cartridges of the same type into one category;

[0065] Step 2. Provide a communication part, and fix the communication part at the opening of the toner cartridge, the communication part includes:

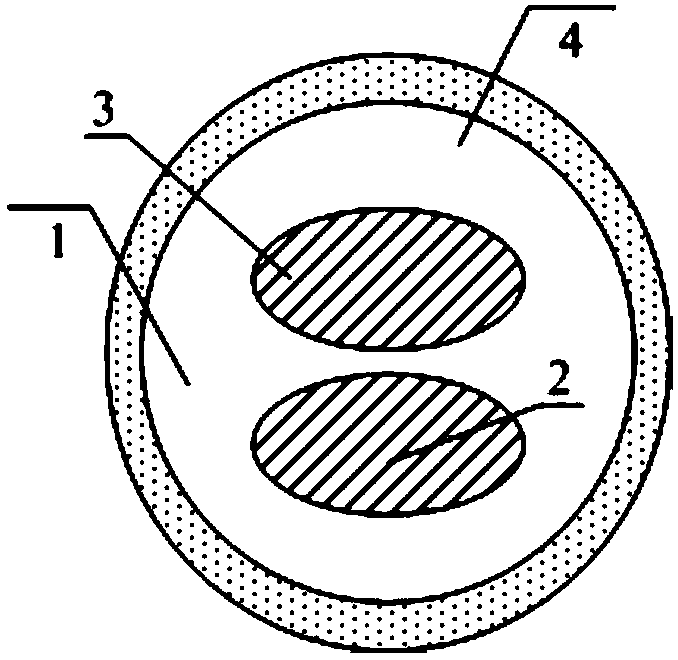

[0066] Body 1, which is detachably fixed to the opening of the toner cartridge and matched with the opening, the body 1 is cylindrical;

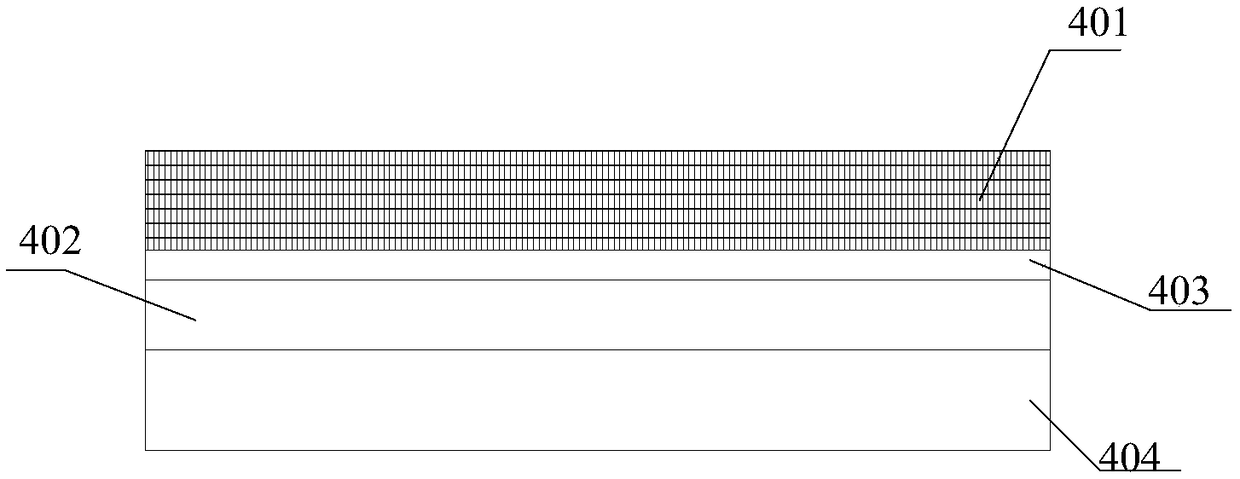

[0067] A first through hole and a second through hole, the first through hole and the second through hole are arranged on the body 1, and the first through hole and the second through hole are connected with the inside of the toner cartridge The cavity is connected, and the second through hole is located below the first through hole;

[0068] A first pipeline and a second pipeline, one end of the first pipeline and the second...

Embodiment 2

[0076] A method for dry recycling carbon powder, comprising the steps of:

[0077] Step 1. First, classify the toner cartridges according to the information of the sensor chip of the toner cartridge, and classify the toner cartridges of the same type into one category;

[0078] Step 2. Provide a communication part, and fix the communication part at the opening of the toner cartridge, the communication part includes:

[0079] Body 1, which is detachably fixed to the opening of the toner cartridge and matched with the opening, the body 1 is cylindrical;

[0080] A first through hole and a second through hole, the first through hole and the second through hole are arranged on the body 1, and the first through hole and the second through hole are connected with the inside of the toner cartridge The cavity is connected, and the second through hole is located below the first through hole;

[0081] A first pipeline and a second pipeline, one end of the first pipeline and the second...

Embodiment 3

[0088] A method for dry recycling carbon powder, comprising the steps of:

[0089] Step 1. First, classify the toner cartridges according to the information of the sensor chip of the toner cartridge, and classify the toner cartridges of the same type into one category;

[0090] Step 2. Provide a communication part, and fix the communication part at the opening of the toner cartridge, the communication part includes:

[0091] Body 1, which is detachably fixed to the opening of the toner cartridge and matched with the opening, the body 1 is cylindrical;

[0092] The first through hole 2 and the second through hole 3, the first through hole and the second through hole are arranged on the body 1, and the first through hole and the second through hole are connected with the toner cartridge The inner cavity of the second through hole is located below the first through hole;

[0093] A first pipeline and a second pipeline, one end of the first pipeline and the second pipeline are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com