A Method for Optimizing the Threshold Strength and Times of Preventive Maintenance of Shipborne Aircraft Sensor System

A preventive maintenance and sensor technology, which is applied in design optimization/simulation, computer-aided design, special data processing applications, etc., can solve the problems of not considering the impact, not considering the impact of maintenance costs, etc., to achieve good economic benefits and long-term maintenance costs Low rate, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be described in detail below:

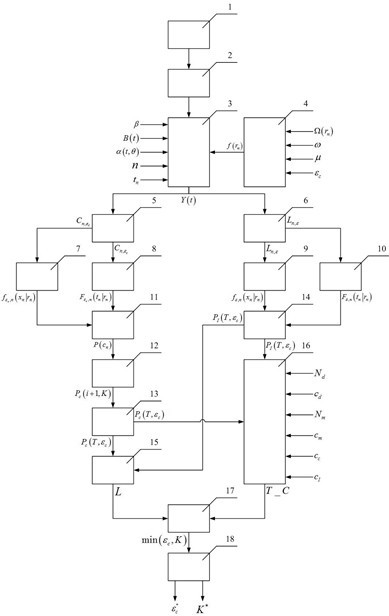

[0023] like figure 1 As shown, a method for the prevention of the carrier-loaded vehicle system for carrier sensor system is optimized, including the carrier sensor system (1), a simplified carrier sensor system model (2), carrier sensor system Prevention and retryation retrogenizer (3), carrier-load sensor system prevention and maintenance remaining degenerative amount probability density function generator (4), carrier sensor system first maintenance and maintenance threshold Generator (5), carrier-loaded sensor system first traffled threshold intensity time L n,ε Generator (6), Probability density solution (7), Cumulative distribution function solution (8), L n,ε Probability density meter (9), L n,ε Cumulative distribution function solution (10), C n T Always Prevent Replacement Probability Solution (11), (i + 1) T Always Prevention Replacement Probability Solution (12), K TA Prevention and Maintenance After Preventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com