A lightweight upper cover of a new energy vehicle battery PACK and a manufacturing method thereof

A technology for a new energy vehicle and a manufacturing method, which is applied in the field of auto body parts, can solve the problems of general mechanical properties of SMC fiber reinforced composite materials, poor insulation of aluminum alloy materials, poor acid and alkali corrosion resistance, and high cost of carbon fiber composite materials. Good fire performance and mechanical properties, good fire performance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

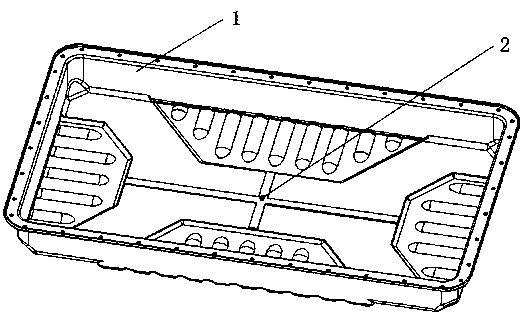

[0030] Please refer to figure 1 and figure 2 , a new energy vehicle battery PACK lightweight cover, including a cover body 1 made of resin and fiber fabric, the cover body is laid with foam reinforcement ribs 2, a total of 2 layers of fiber fabric, and the fiber fabric is glass fiber One or more of fabrics, carbon fiber fabrics, and basalt fabrics. The reinforcing ribs are laid in a cross shape, the reinforcing ribs are foam reinforcing ribs or rigid reinforcing ribs, and a small piece of fiber fabric for edge sealing is laid beside the reinforcing ribs. The resin is a flame-retardant thermosetting resin, and the flame-retardant thermosetting resin is an unsaturated resin, epoxy resin, phenolic resin or vinyl resin. The lightweight upper cover of the new energy vehicle battery PACK also includes a fireproof paint layer sprayed on the outer surface. The wall thickness of the lightweight upper cover of the new energy vehicle battery PACK is 1mm-2mm.

[0031] The manufacturi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com