A battery module for carrying out overcurrent by lamination

A battery module and overcurrent technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of copper row temperature rise, current loss, and overcurrent distance, etc., to solve the problem of excessive temperature rise, Improve productivity and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

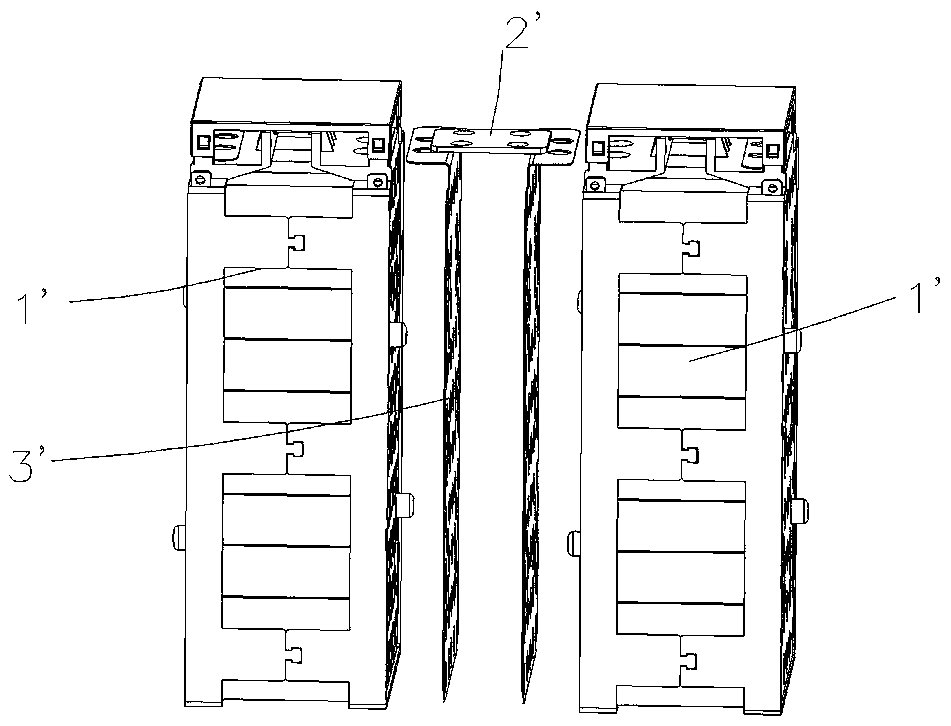

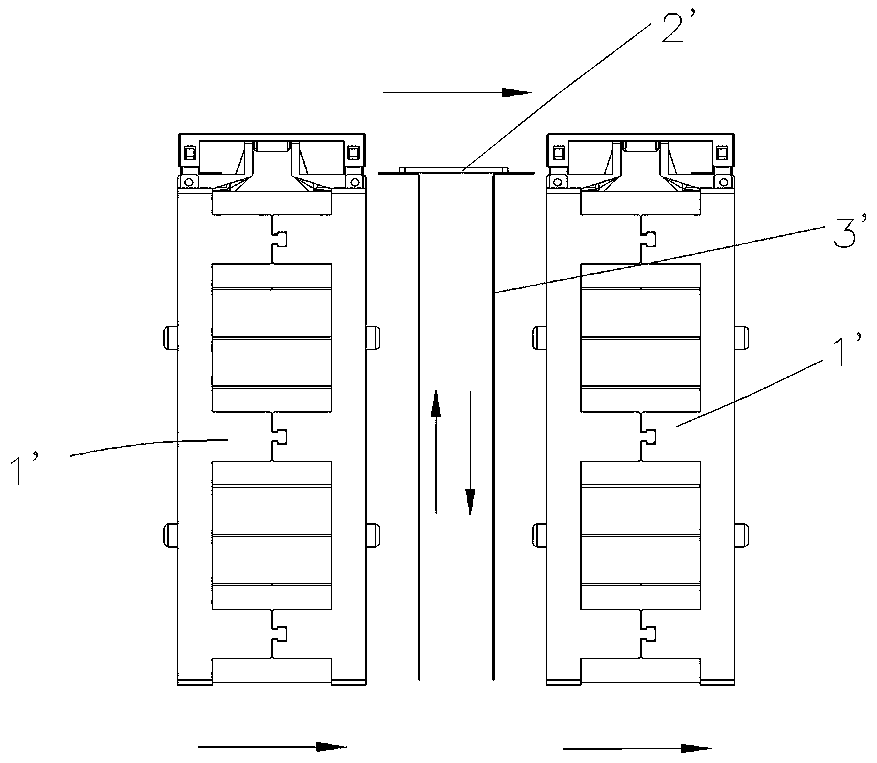

[0020] Such as Figure 3 to Figure 5 As shown, a battery module for overcurrent through pressing includes a plurality of battery modules 1 , a plurality of intermediate copper or aluminum sheets 2 , a plurality of long screws 3 , and two end plates 4 .

[0021] A plurality of battery modules 1 are arranged side by side, a middle copper sheet or aluminum sheet 2 is arranged between every two adjacent battery modules 1, and the two battery modules 1 arranged at the outermost end are respectively provided with an end plate 4, through a plurality of The long screw 3 connects the plurality of battery modules 1 , the plurality of intermediate copper or aluminum sheets 2 , and the end plates 4 to form a battery module.

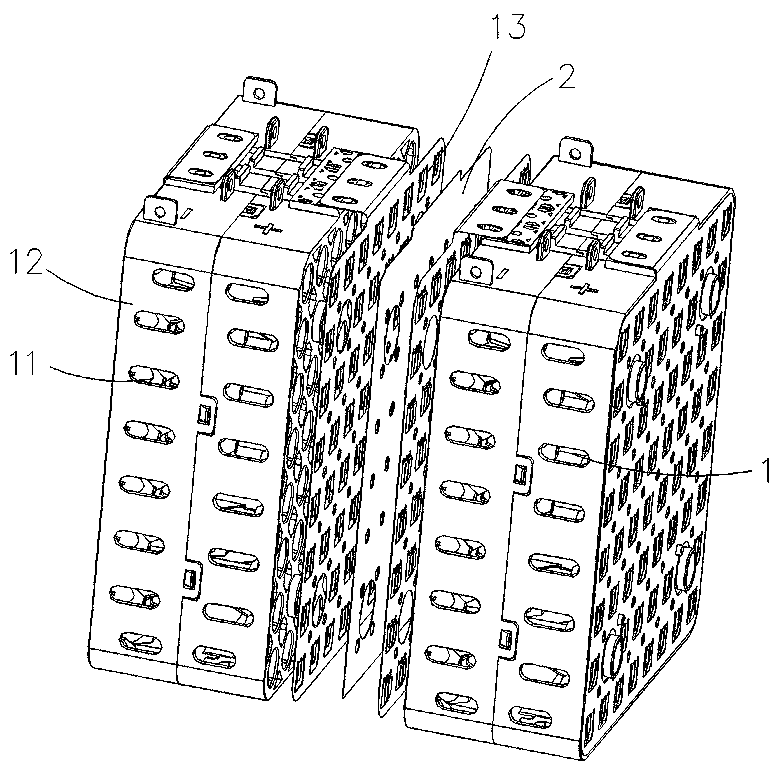

[0022] The battery module 1 includes a cell 11, a bracket 12, and a nickel sheet 13; the cell 11 is arranged in the bracket 12; the cell 11 and the bracket 12 are welded to the nickel sheet 13 by resistance .

[0023] Description of working process:

[0024] The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com