A nodal grounding electrode

A technology of grounding body and grounding conductor, which is applied in the direction of connecting contact materials to achieve the effect of saving manpower and cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

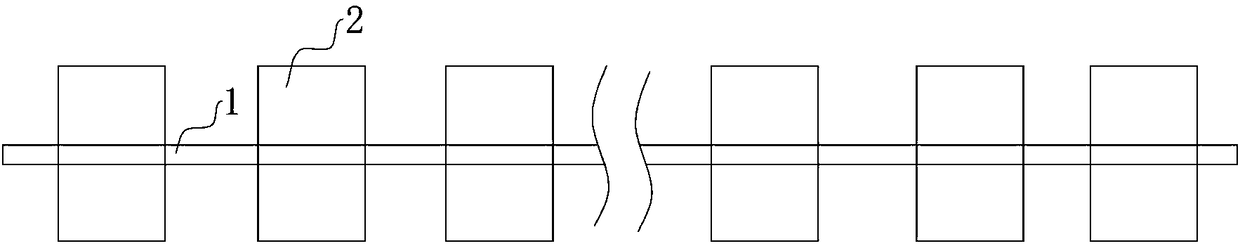

[0026] Such as figure 1 As shown, the present invention provides a hub-type grounding body, which includes a ground conductor 1 for laying in a pre-buried trench and a plurality of ground hubs 2 distributed along the length direction of the ground conductor 1 . The grounding conductor 1 includes an inner core and an anti-corrosion layer covering the outside of the inner core, wherein at least one inner core is provided, and each inner core is composed of single or multiple conductive wires, and the specific conductive wires are various conductive metals or Composite conductors composed of conductive metals can also be conductive graphite or conductors made of graphite and other non-metallic conductors. The structure of the inner core is covered by an anti-corrosion layer to avoid the grounding conductor 1 being easily damaged due to being buried underground for a long time. In case of corrosion, ensure the safety protection of the grounding body.

[0027] As mentioned above, ...

Embodiment 2

[0029] The difference from Embodiment 1 is that the grounding conductor 1 is laid vertically underground, so that multiple grounding hubs 2 are distributed vertically underground, that is, in places with high soil resistivity, when the buildable area is constant, only the A vertical trench is opened underground along the direction perpendicular to the ground, and the grounding joints 2 are vertically distributed in the trench. Even if the grounding resistance is effectively reduced, large-scale excavation of soil is not required, which effectively saves manpower and cost.

[0030] The jointed grounding body of the present invention utilizes one or more grounding conductors 1 to connect multiple grounding joints 2 to form a jointed grounding grid. The joints 2 are distributed in the trench, so that each grounding joint 2 can be in close contact with the soil in all directions and act independently, reducing the contact resistance between a single grounding joint 2 and the surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com