Manufacturing method and PCB of groove bottom pattern stepped groove

A manufacturing method and technology of stepped grooves, which are applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit and other directions, can solve the problems of complex process, many structural design restrictions, and difficult manufacturing, so as to reduce the difficulty of operation and improve work efficiency. , The effect of the simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

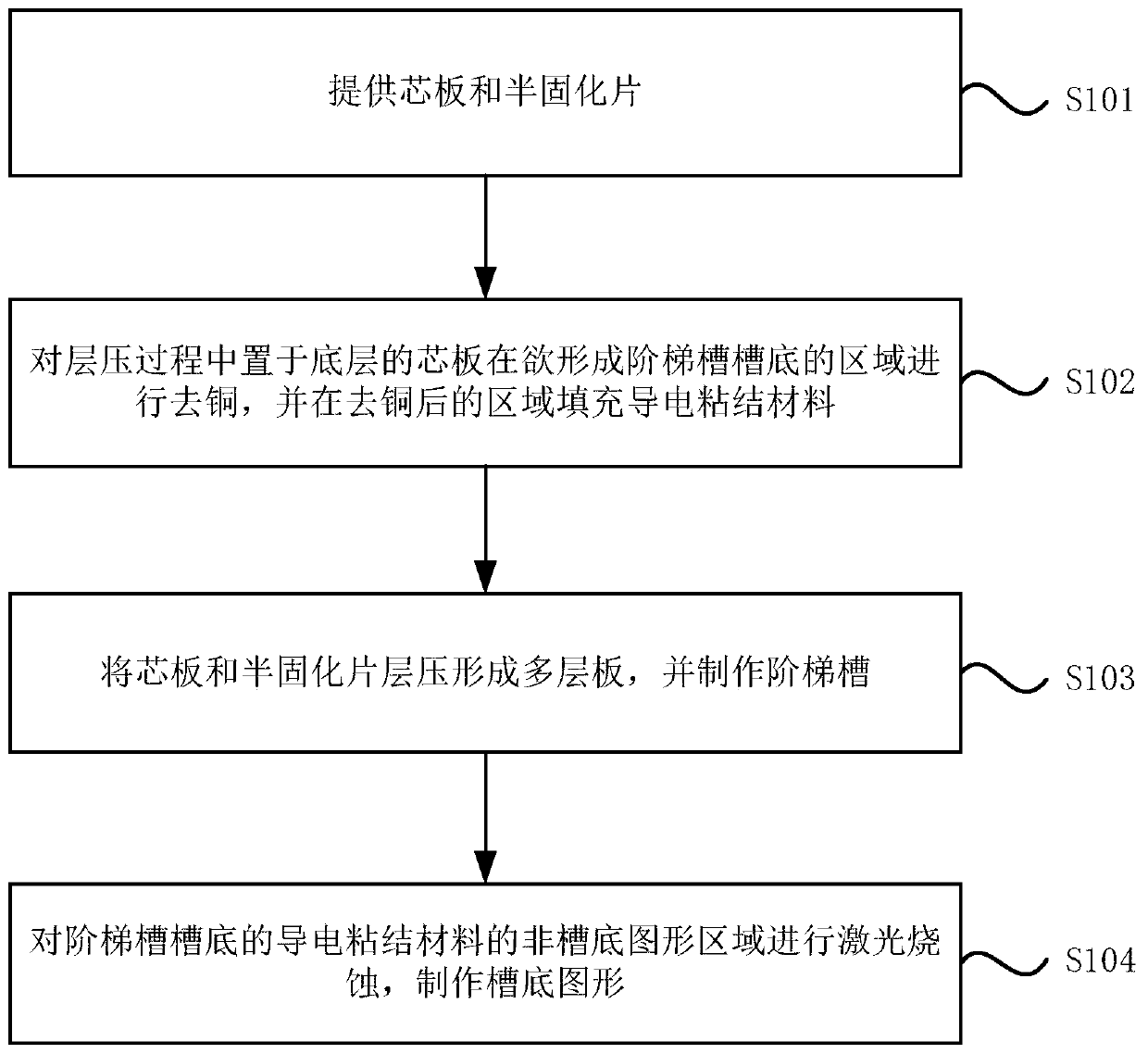

[0034] see figure 1 , the present embodiment 1 provides a method for manufacturing a stepped groove with a groove bottom pattern, comprising the steps of:

[0035] S101. Provide core board and prepreg.

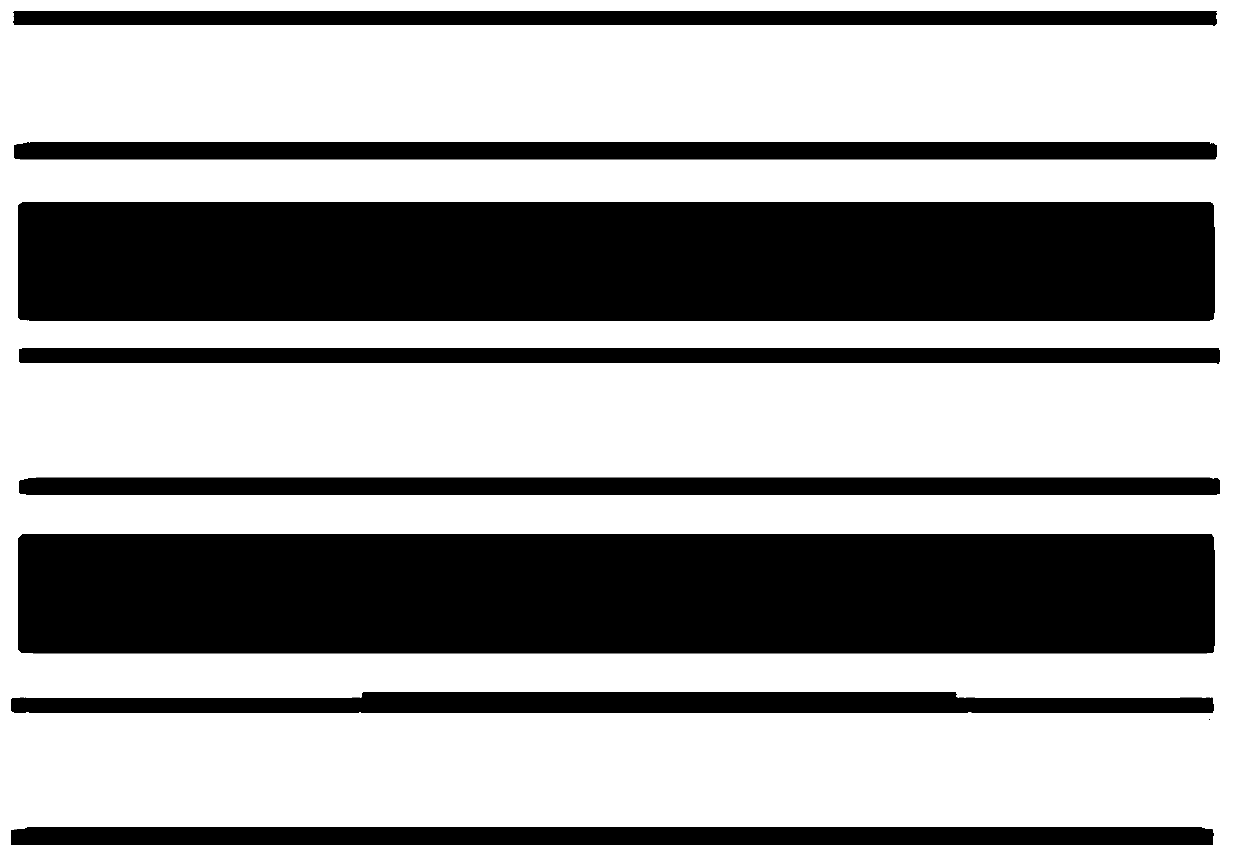

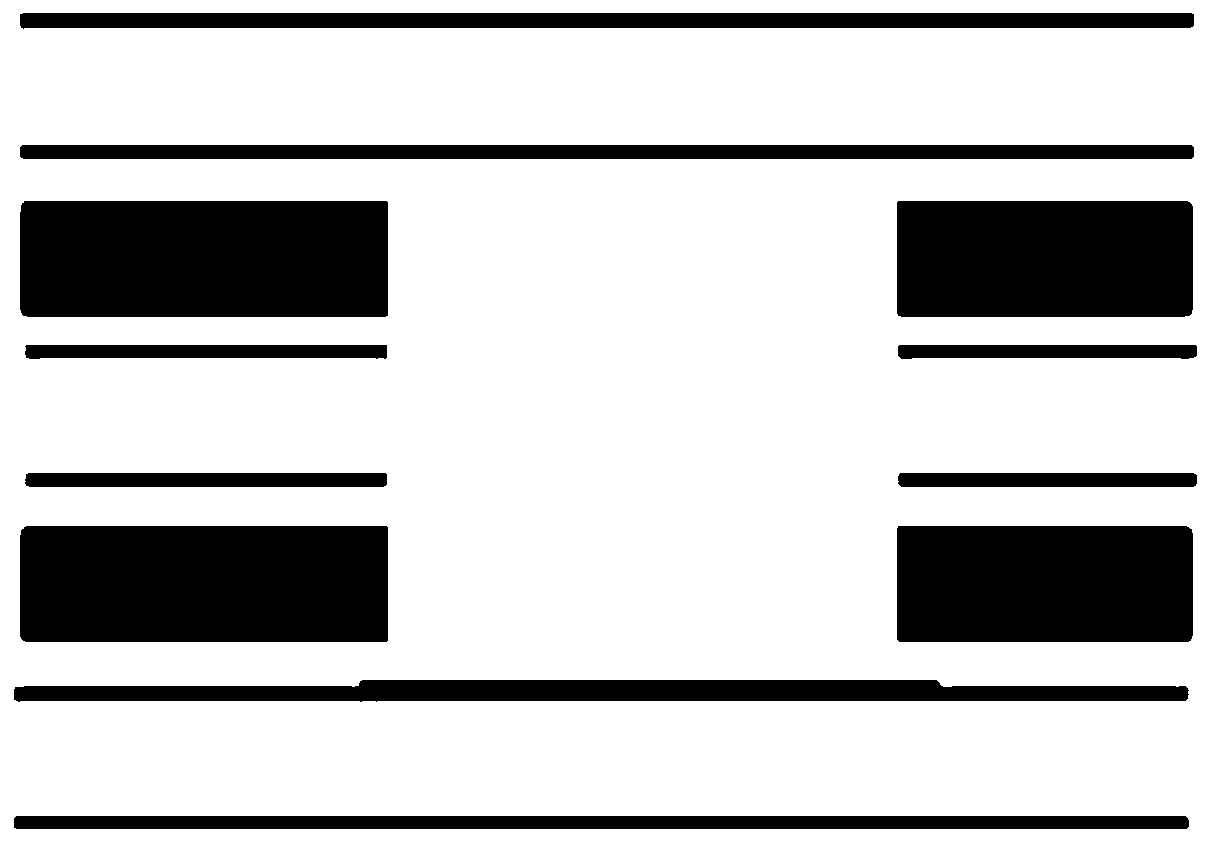

[0036] S102, remove copper in the area where the bottom of the stepped groove is to be formed on the core board placed on the bottom layer during the lamination process, and fill the area after the copper removal with conductive bonding material, such as figure 2 shown.

[0037] Wherein, the composition of the conductive bonding material includes but not limited to resin matrix, conductive particles, dispersion additives and auxiliary agents, commonly used matrix is generally thermosetting adhesive such as epoxy resin, silicone resin, polyimide resin , phenolic resin, polyurethane, acrylic resin and other adhesive systems. After curing, these adhesives form the molecular skeleton structure of conductive bonding materials, provide mechanical properties and bonding perform...

Embodiment 2

[0057] The second embodiment provides a PCB, including a stepped groove with a groove bottom pattern, and the stepped groove is manufactured according to the manufacturing method provided in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com