A method of making a stepped groove

A manufacturing method and a stepped groove technology are applied in the fields of printed circuit manufacturing, multi-layer circuit manufacturing, printed circuit, etc., which can solve the problems of poor versatility, complicated manufacturing process, and difficult manufacturing, and achieve strong versatility, simplify the manufacturing process, The effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

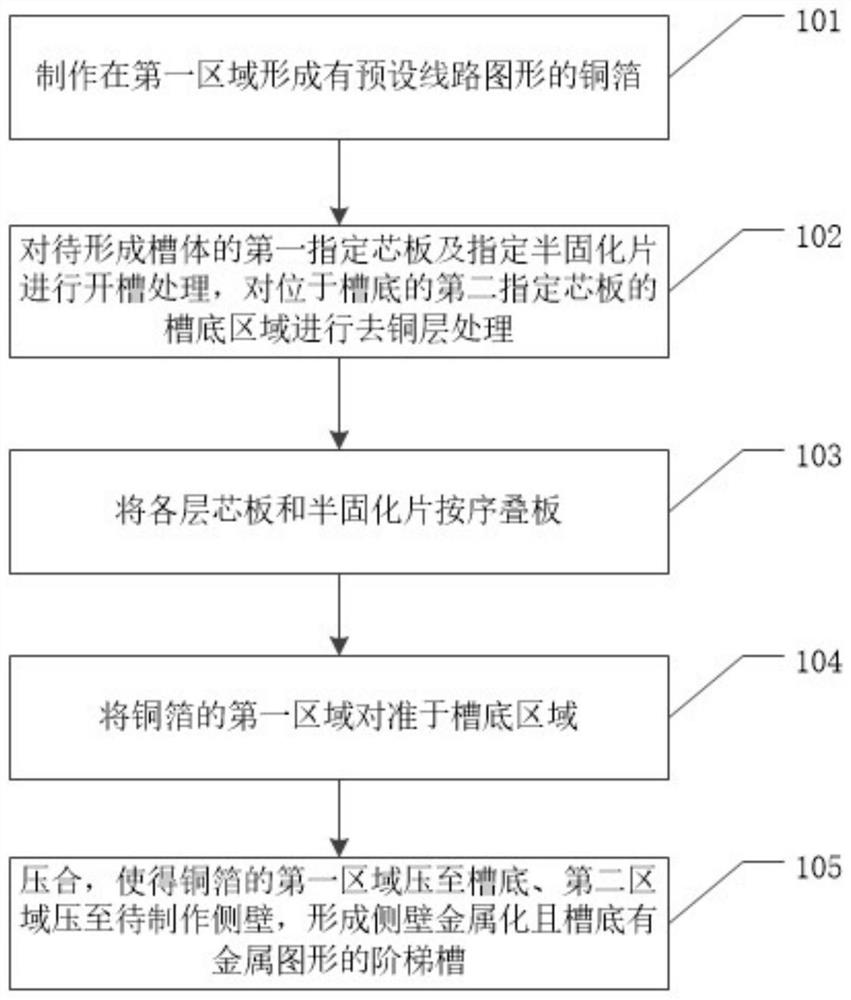

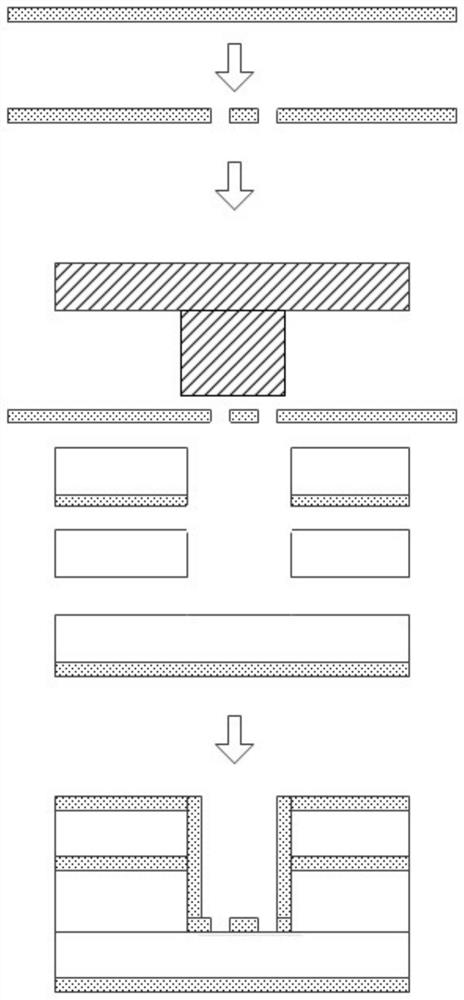

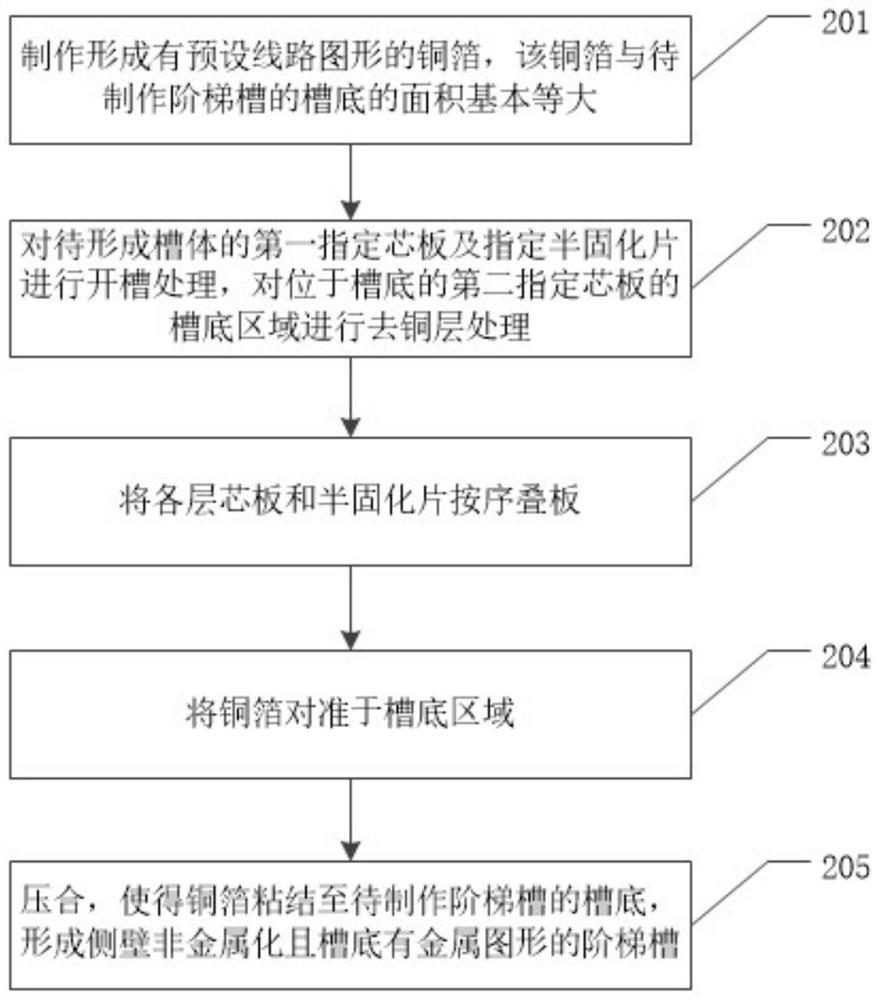

[0041] The manufacturing method of the stepped groove provided by the present invention, the main idea is:

[0042] Making a copper foil with a preset circuit pattern; the copper foil includes at least a first area, the first area is consistent with the area of the groove bottom of the stepped groove to be made, and the preset circuit pattern is formed in the first area;

[0043] Perform groove processing on the first designated core board and designated prepreg to be formed into the tank body, and perform copper removal treatment on the groove bottom area of the second designated core board at the bottom of the tank;

[0044] Stack each layer of core board and each layer of prepreg in sequence;

[0045] Aligning the first area of the copper foil to the bottom area of the groove;

[0046] Pressing at high temperature causes the first area of the copper foil to bond to the bottom area of the groove to form a stepped groove with a preset circuit pattern at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com