Ashore breeding and feeding system with high-pressure gas flushing feeding machines

A technology of high-pressure gas and feeding system, which is applied in the field of feeding system for feeding feed in the breeding box, can solve the problems affecting the growth and death of abalone, and the error of hand feeling measurement, etc., and achieve the advantages of novel and simple structure, safe operation and saving investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present application will be further described in detail through the following embodiments in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present application.

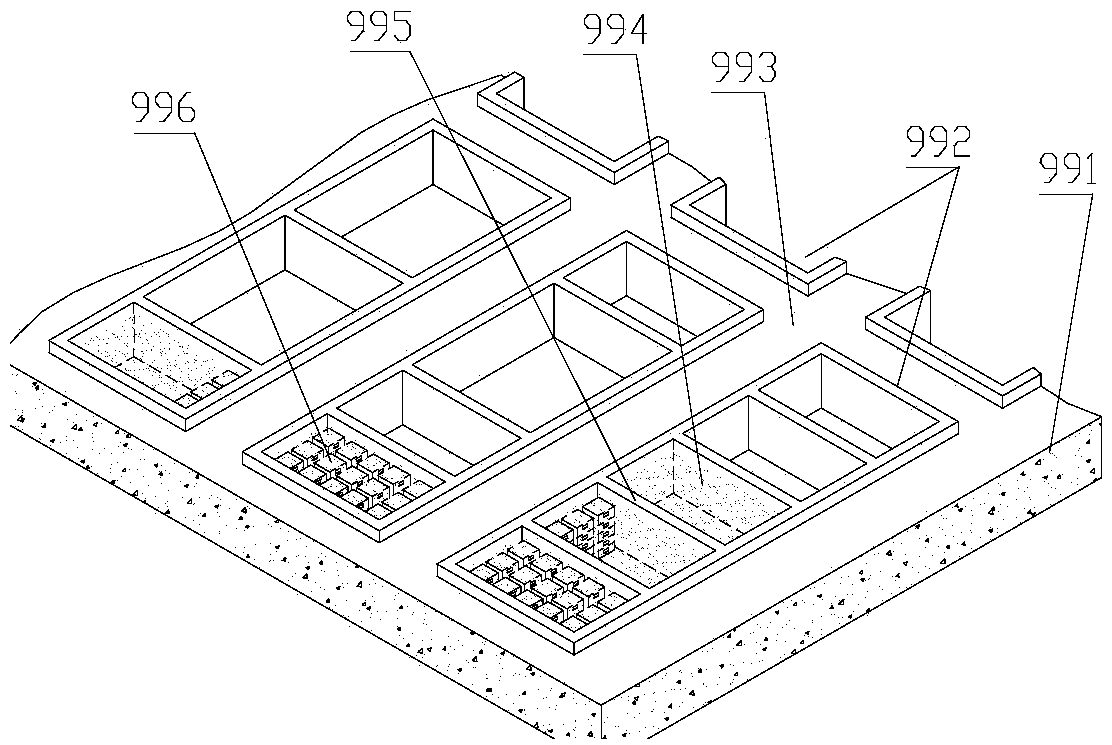

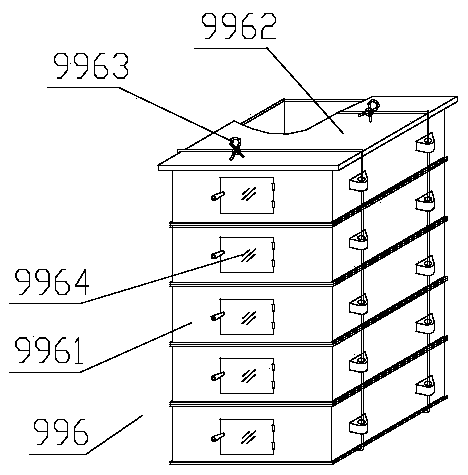

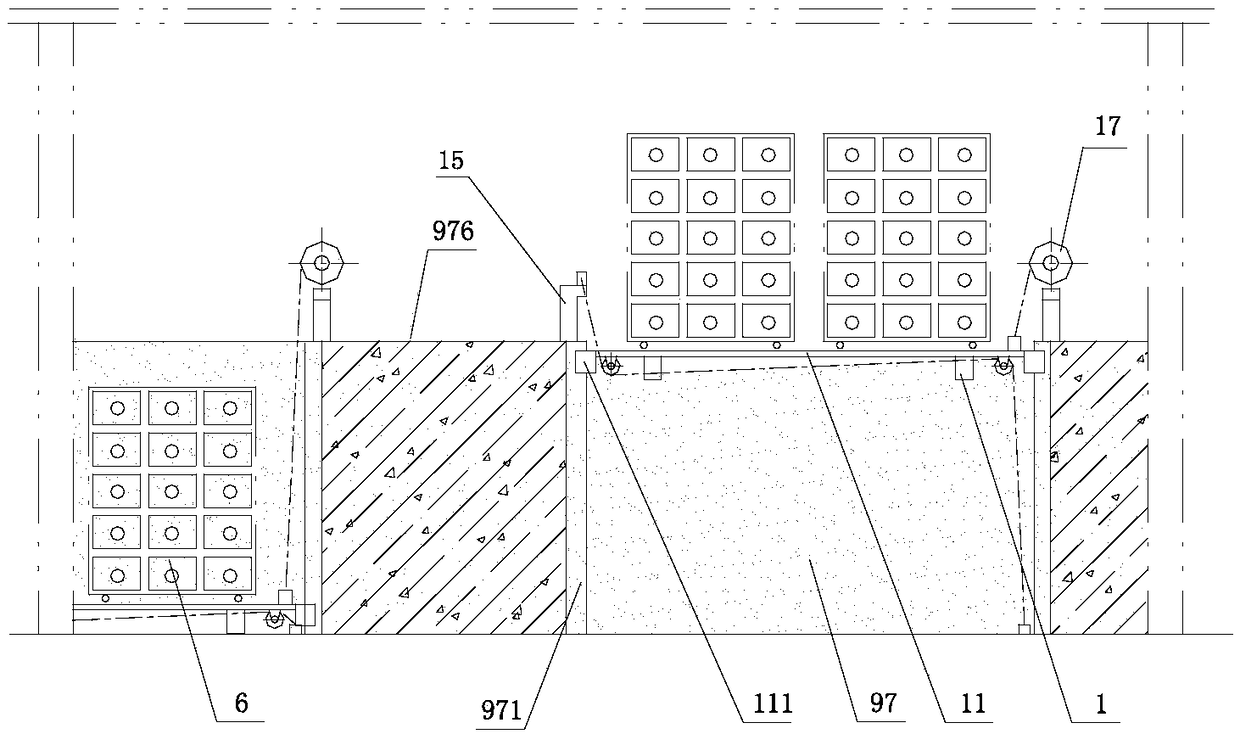

[0032] Such as image 3 , Figure 4 , Figure 5 As shown, it is the front view, side view, and top view of a shore breeding feeding system with a high-pressure gas flushing feeder described in the first embodiment of the application. The feeding system includes a breeding pond 97, a breeding cabinet 6, elevator 1, feeder 8; Described culture pool 97 is set up under the workshop floor (or builds on workshop ground) one by one, is provided with workshop walkway 976 between adjacent culture ponds; Workshop walkway can be wide or narrow, wide The workshop walkway can allow the culture cabinet 6 to move and run on it; when the culture pond is built on the workshop floor, and the edge of the pool surface is hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com