Food processing device

A food processing device and component technology, which is applied to mixers with rotating stirring devices, transportation and packaging, mixers, etc., can solve the problem of small stirring area, achieve larger contact area, good stirring effect, and easy discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

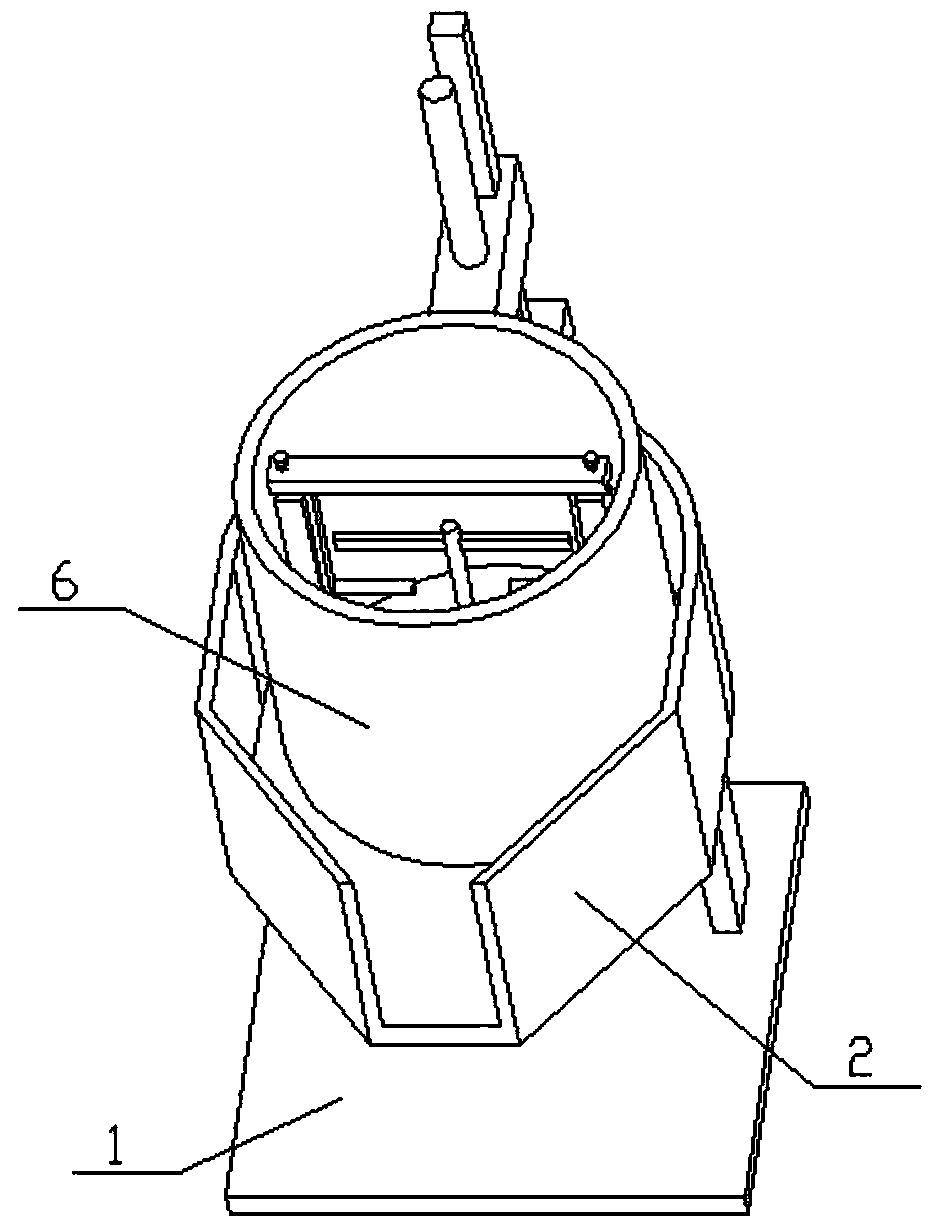

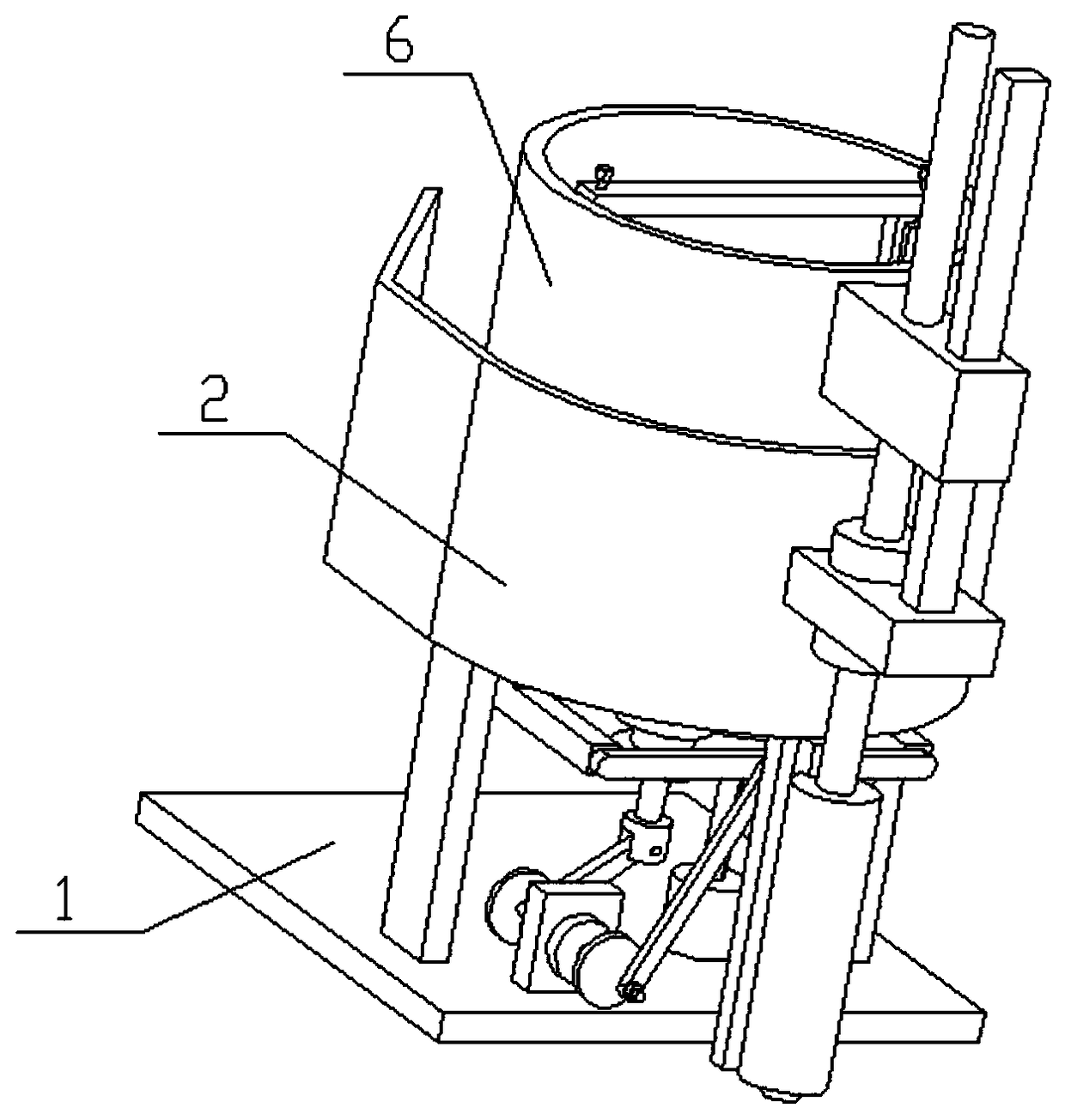

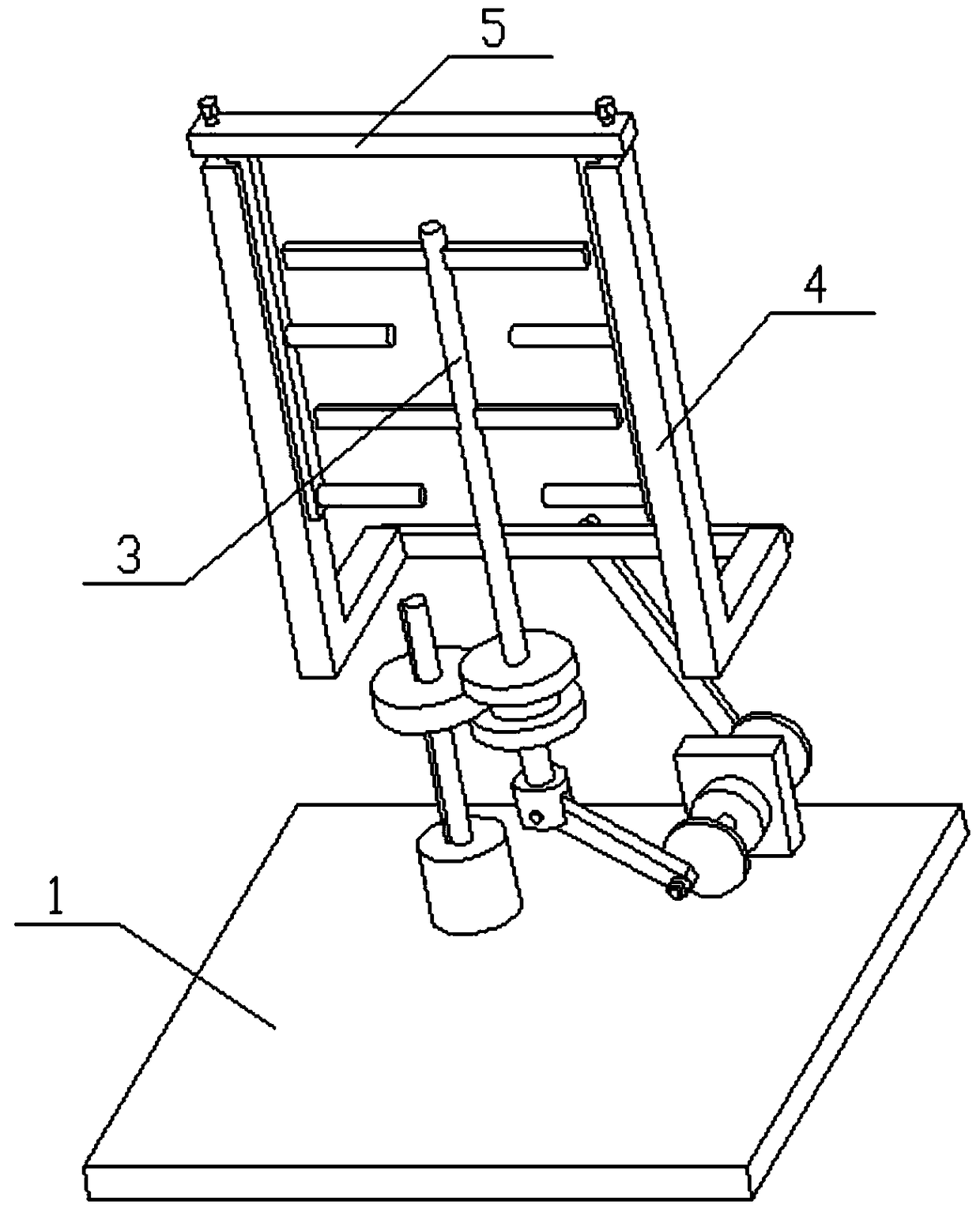

[0029] Combine below Figure 1-13 To illustrate this embodiment, the present invention relates to the field of food processing, more specifically, a food processing device, including a bottom frame assembly 1, a tank box assembly 2, a stirring assembly 3, a reciprocating frame 4, a blocking rod assembly 5 and a cover cylinder assembly 6. In the present invention, the stirring shaft 3-2 can reciprocate up and down while rotating, which increases the stirring range of the stirring blade 3-1, and the stirring effect is better. The four blocking rods 5-3 rotate on the stirring blade 3-1 It is equivalent to stirring the dry food material with the reverse rotation of the stirring blade 3-1, further improving the mixing effect, and the four blocking rods 5-3 will also reciprocate up and down to increase the contact area with the dry food material; after the stirring is completed, the tank The box 2-1 can be tilted to facilitate discharging.

[0030] The tank box component 2 is fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap