Preparation method for Fe-N-C catalytic material with controllable edge active sites

A technology of active sites and catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. The internal catalytic active sites are fully exposed to achieve good ORR catalytic activity and reduce the reaction barrier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

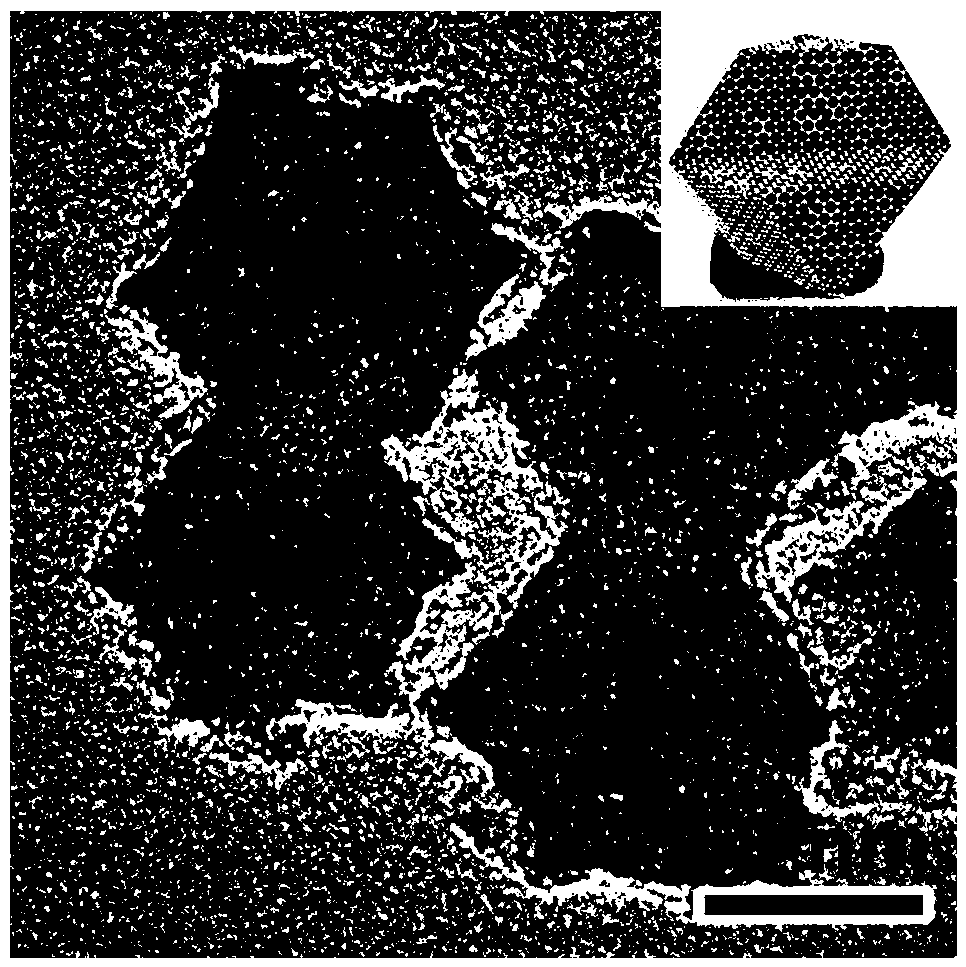

[0025] a. Disperse 28.71mmol of 2-methylimidazole in 40mL of methanol, and quickly add 40mL of 3.6M Zn(NO 3 ) 2 methanol solution, stirred at room temperature for 24 hours, washed with methanol and centrifuged, and the obtained precipitate was dried in a vacuum oven;

[0026] b. Transfer the dried precipitate to a porcelain boat, put it in a tube furnace, and feed it with N 2 After exhausting the air, heat to 900°C and calcined for 3h;

[0027] c. Add 0.5M H to the calcined material 2 SO 4 Submerge the material completely, keep the temperature at 60°C for 24 hours, wash until neutral, and dry the precipitate in a vacuum oven.

Embodiment 2

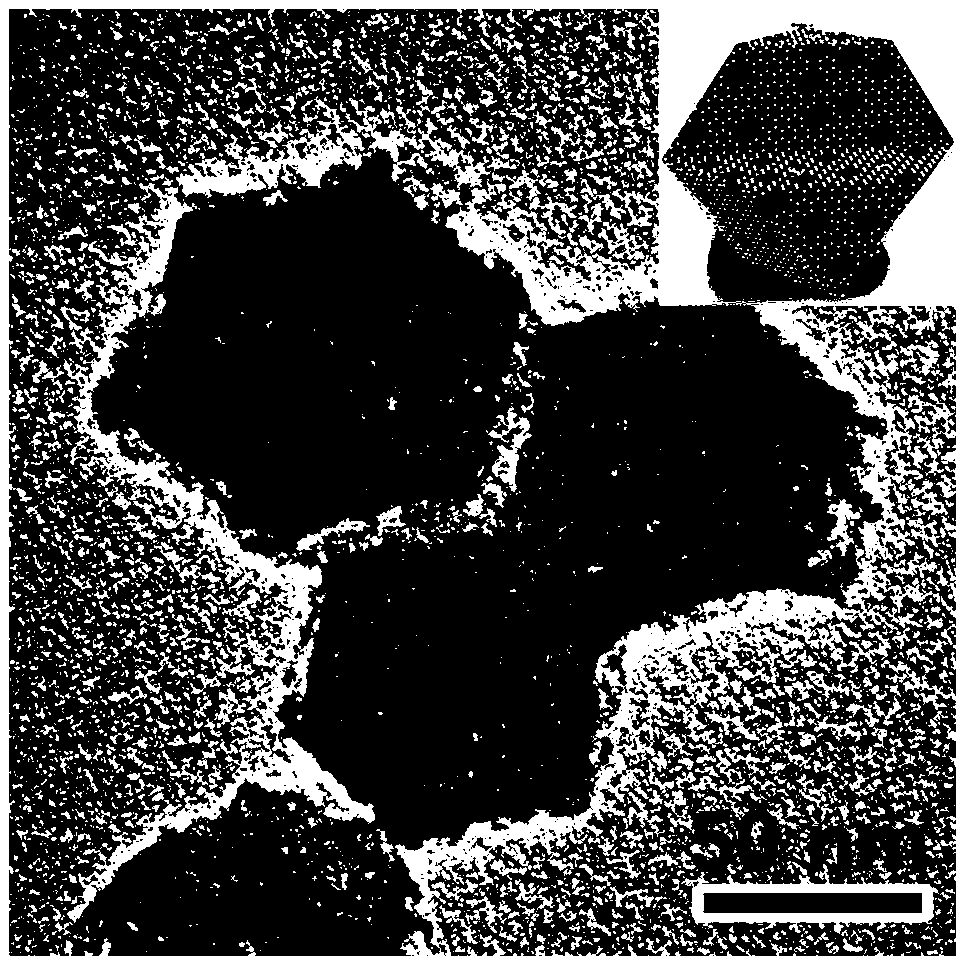

[0029] a. Disperse 28.71mmol 2-methylimidazole and 8mg iron phthalocyanine in 40mL methanol, quickly add 40mL3.6M Zn(NO 3 ) 2 methanol solution, stirred at room temperature for 24 hours, washed with methanol and centrifuged, and the obtained precipitate was dried in a vacuum oven;

[0030] b. Transfer the dried precipitate to a porcelain boat, put it in a tube furnace, and feed it with N 2 After exhausting the air, heat to 900°C and calcined for 3h;

[0031] c. Add 0.5M H to the calcined material 2 SO 4 Submerge the material completely, keep the temperature at 60°C for 24 hours, wash until neutral, and dry the precipitate in a vacuum oven.

Embodiment 3

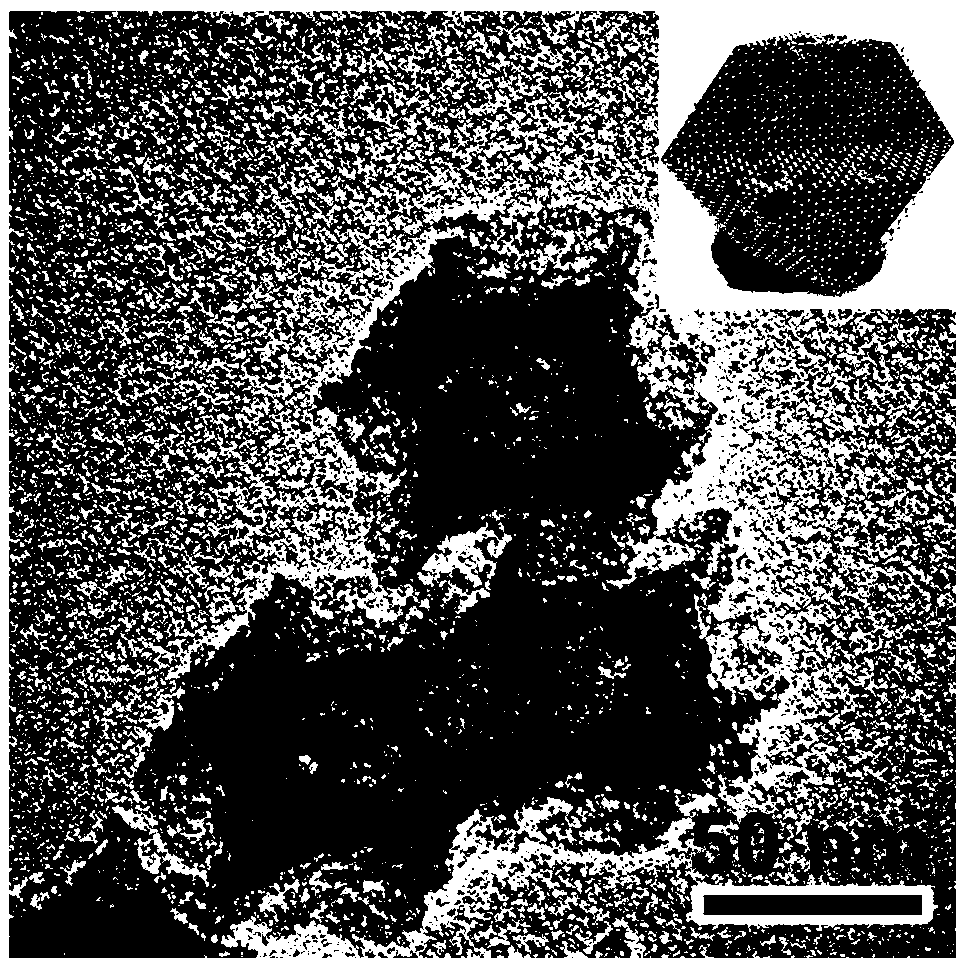

[0033] a. Disperse 28.71mmol 2-methylimidazole and 16mg iron phthalocyanine in 40mL methanol, quickly add 40mL3.6M Zn(NO 3 ) 2 methanol solution, stirred at room temperature for 24 hours, washed with methanol and centrifuged, and the obtained precipitate was dried in a vacuum oven;

[0034] b. Transfer the dried precipitate to a porcelain boat, put it in a tube furnace, and feed it with N 2 After exhausting the air, heat to 900°C and calcined for 3h;

[0035] c. Add 0.5M H to the calcined material 2 SO 4 Submerge the material completely, keep the temperature at 60°C for 24 hours, wash until neutral, and dry the precipitate in a vacuum oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com