Mechanical arm system and control method of mechanical arm system

A manipulator and square column technology, applied in the field of manipulators, can solve the problems of low production capacity, low degree of automation, and inability to achieve high-precision transfer of processed workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

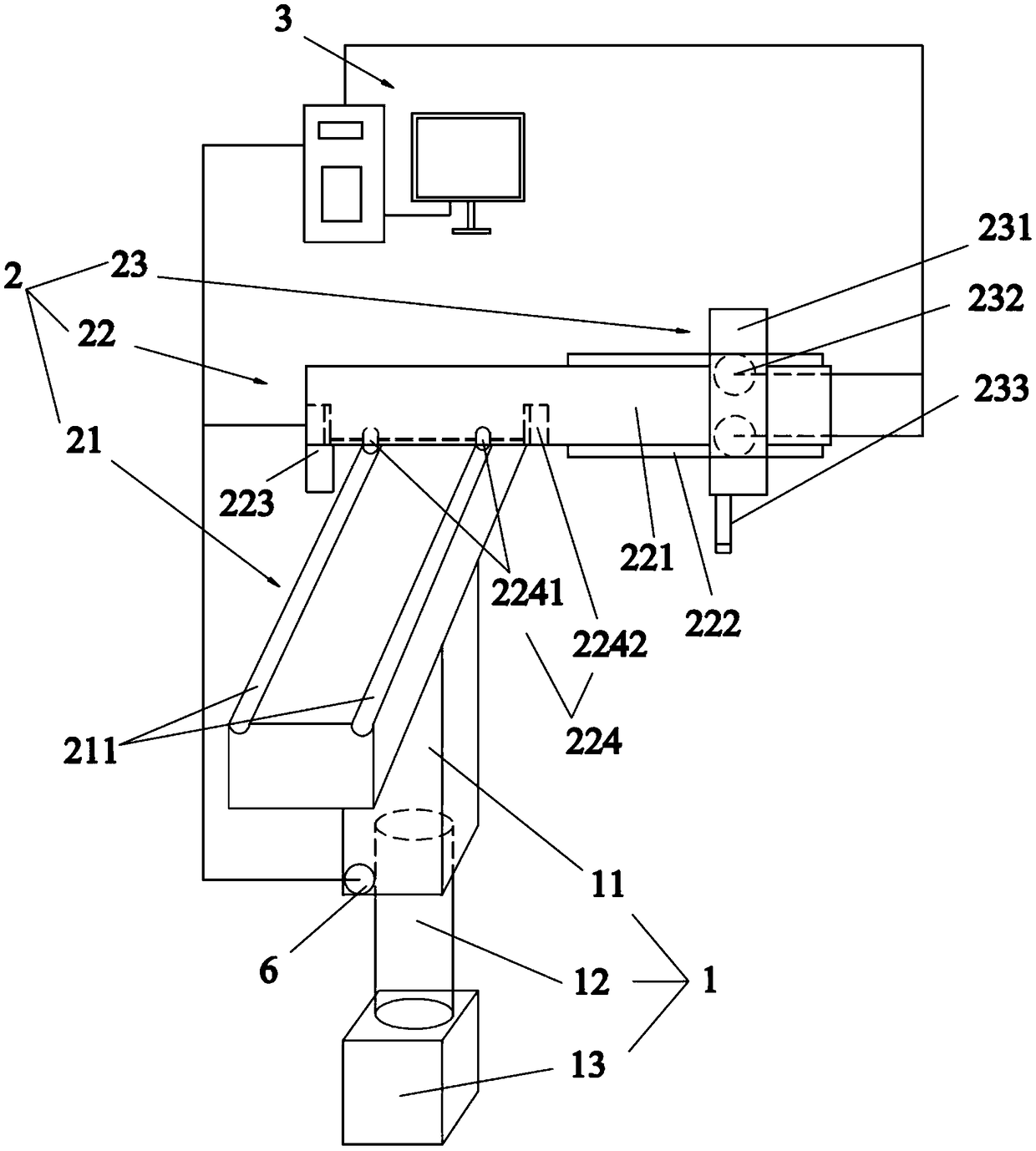

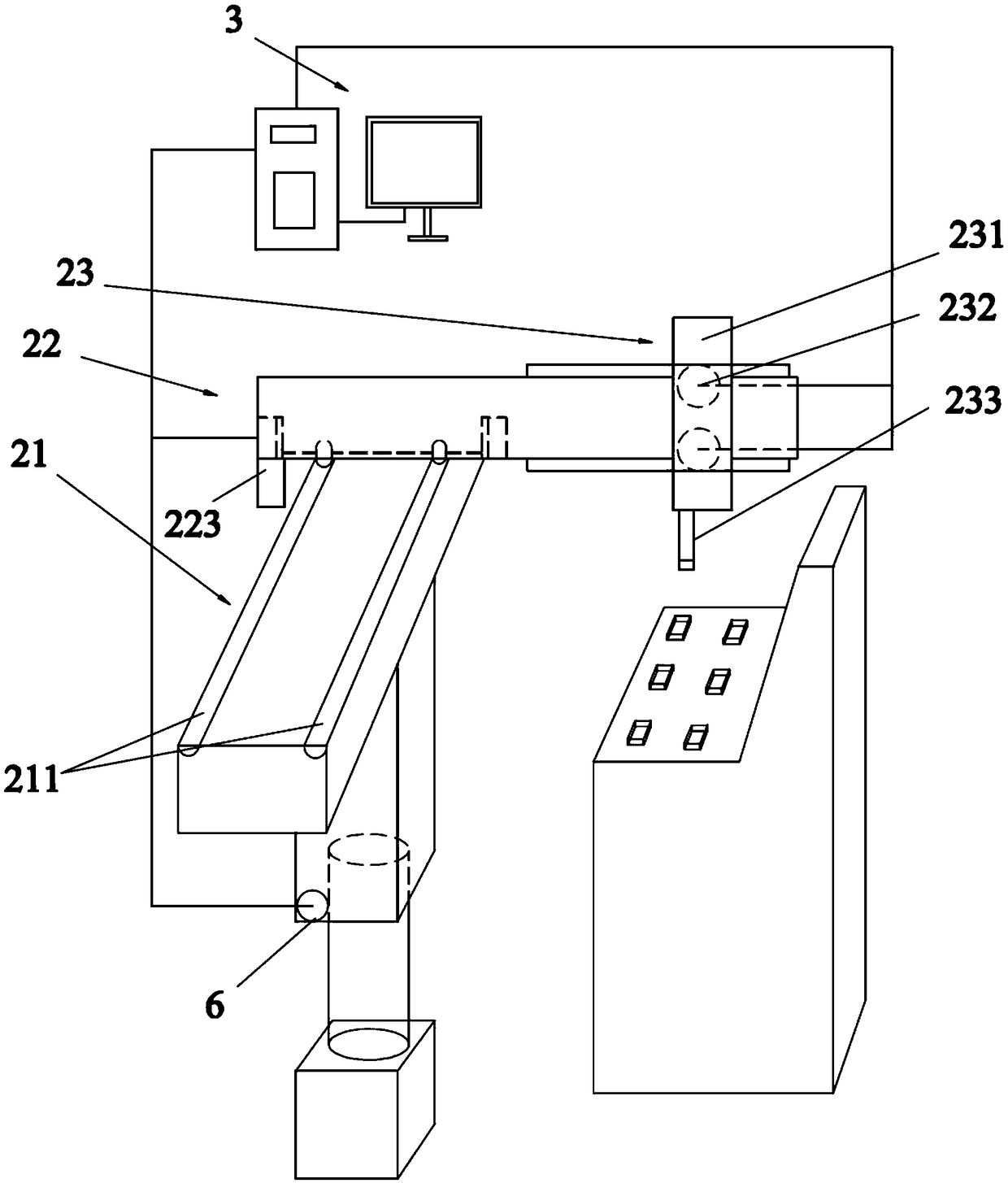

[0028] Such as Figure 1~2 As shown, the manipulator system includes a lifting device 1, a plane kinematic mechanism 2 and a computer 3, and the lifting device 1 and the plane kinematic mechanism 2 are electrically connected to the computer 3, and the plane kinematic mechanism 2 includes a load longitudinal beam 21, a movable beam 22 and Replaceable operating part 23, the beam 22 is slidingly connected to the load longitudinal beam 21, and the operating part 23 is slidingly connected to the beam 22. The operating part 23 includes a main body 231, an electric wheel 232 arranged in the main body 231 and a manipulator 233 fixed to the main body 231 . The crossbeam 22 is slidably connected with the load longitudinal beam 21, which helps to realize the forward and backward movement of the crossbeam 22, and the sliding connection between the operation part 23 and the crossbeam 22, which helps to realize the left and right movement of the operation part 23, and the movable crossbeam ...

Embodiment 2

[0033] The difference from Embodiment 1 is that the manipulator 233 in this embodiment is a mechanical claw for grabbing heavy objects. In the logistics industry, the height of the shelf limits the storage capacity of the warehouse. Using a manipulator system with mechanical claws can put heavier goods on higher shelves and increase the storage capacity of the warehouse.

[0034] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0036] The difference from Embodiment 1 is that the manipulator 233 in this embodiment is an electric drill used for drilling. In the circuit board drilling industry, the efficiency of manual drilling is low and the accuracy is relatively low. Using a manipulator system with an electric drill can improve the accuracy of drilling and the efficiency of drilling.

[0037] Other structures are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com