Waste material treatment device for steel plate machining

A waste treatment and steel plate technology, which is applied to metal processing equipment, metal processing machinery parts, cleaning methods using gas flow, etc., can solve the problems of time-consuming, labor-intensive, inconvenient cleaning, and low efficiency of waste and iron filings, and achieve time saving Labor-saving efficiency and easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

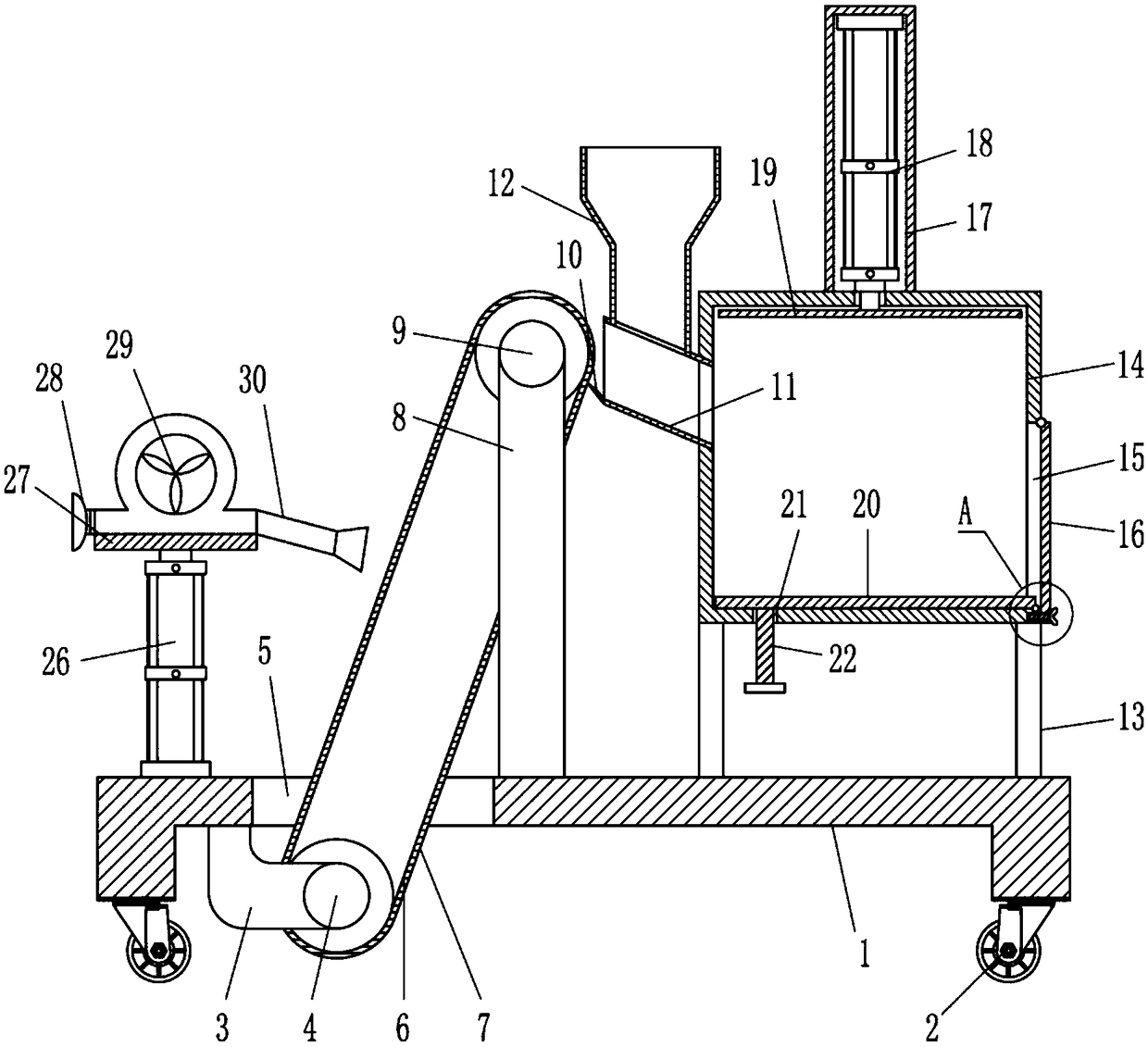

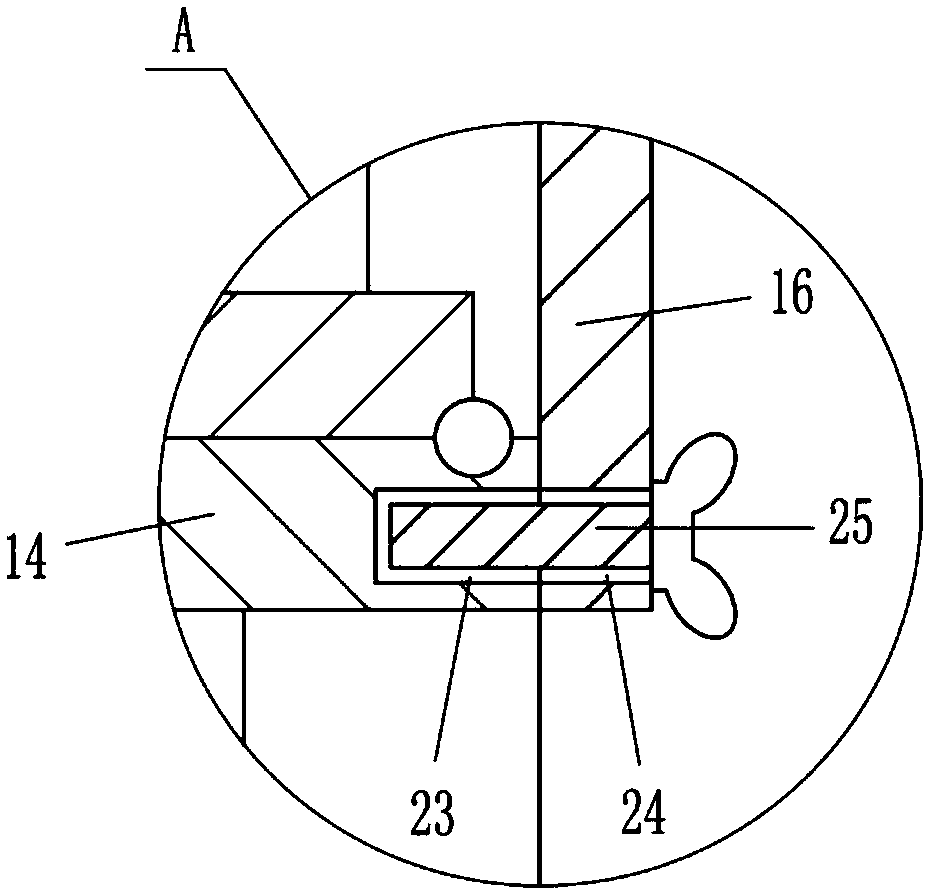

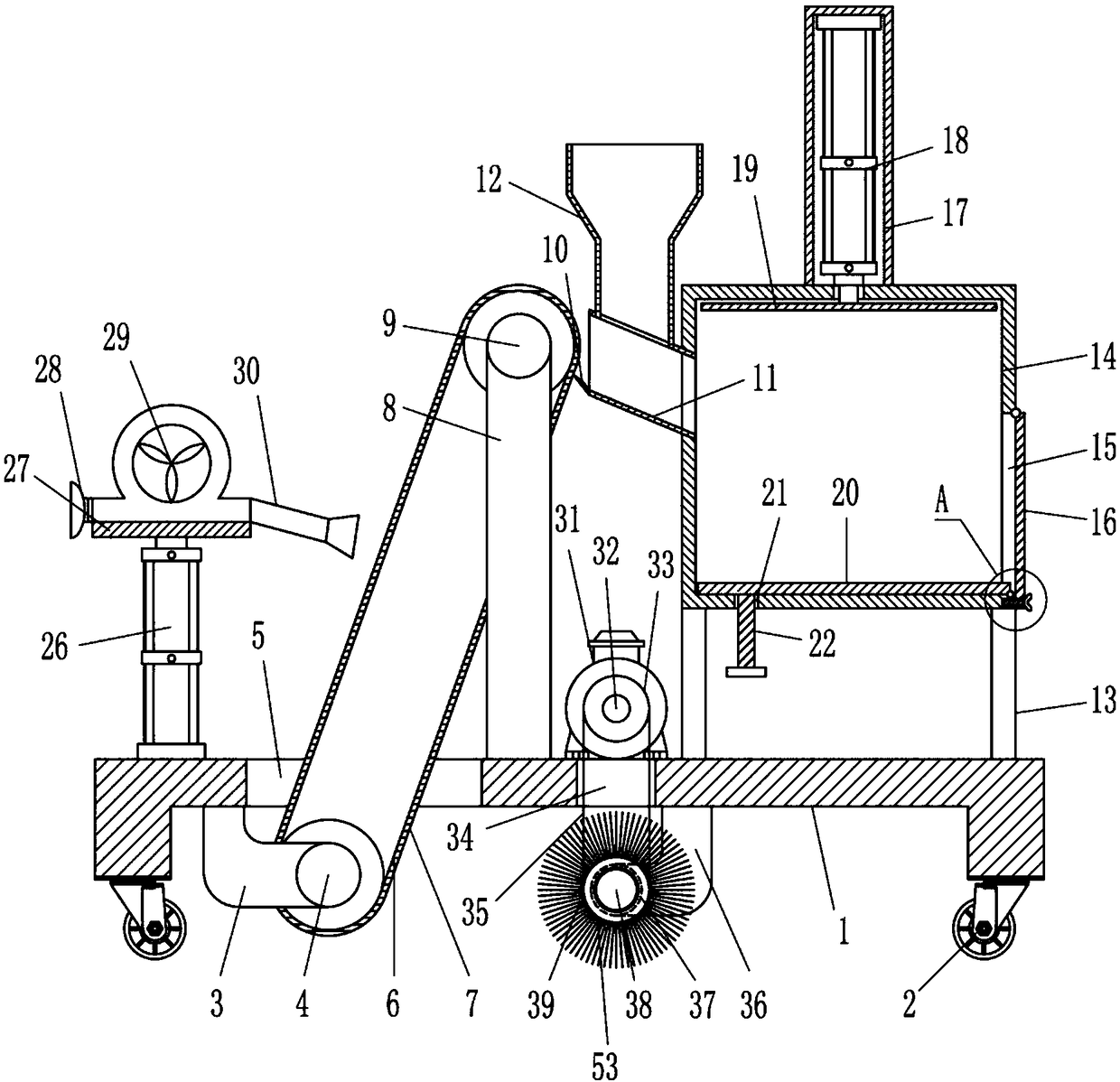

[0028] A waste treatment device for steel plate processing, such as Figure 1-5 As shown, it includes an inverted concave base 1, a universal wheel 2, a first L-shaped bracket 3, a driven wheel 4, a first conveyor belt 6, a permanent magnet magnetic belt 7, a straight bracket 8, a driving wheel 9, a scraper 10, the first A feed pipe 11, a second feed pipe 12, a pillar 13, a processing box 14, a baffle plate 16, a bottomless installation frame 17, a first telescopic cylinder 18, an upper compacting plate 19, bolts 25, a second telescopic cylinder 26 , mounting plate 27, dust collection cover 28, dust extraction fan 29 and dust outlet pipe 30; the universal wheel 2 is installed on the bottom of the inverted concave base 1, and the driven wheel 4 is fixed on the inverted concave base through the first L-shaped bracket 3 1 bottom, the inverted concave base 1 is provided with the first through hole 5 for the first conveyor belt 6 to pass through, the driving wheel 9 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com