A maglev train

A technology for maglev trains and trains, which is applied to electric vehicles, railway car bodies, vehicle components, etc., can solve the problems of poor structural stability of T-shaped guide rails and car bodies, prone to subversion accidents, and inconvenient maintenance, so as to protect the surrounding environment. , the effect of improving comfort and safety, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

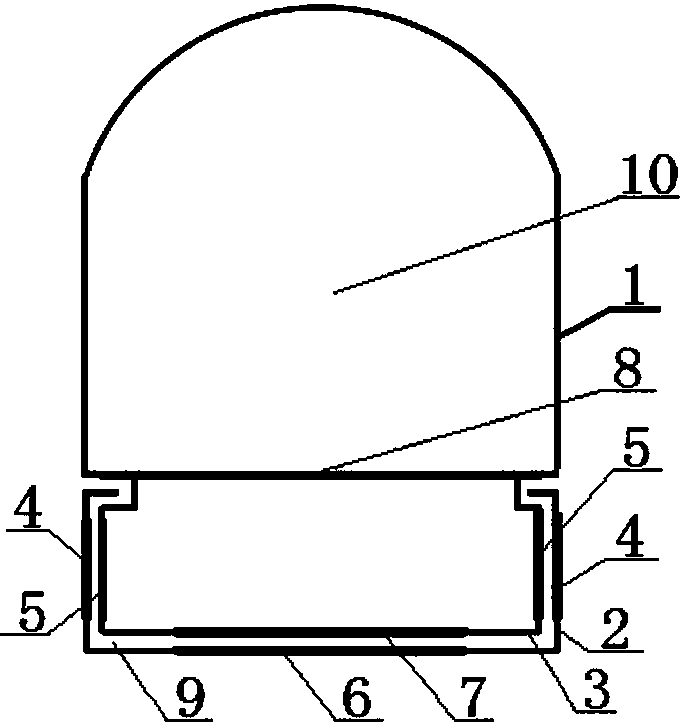

[0022] see figure 1 As shown, the present invention includes a matching car body 1 and guide rails 2 .

[0023] Among them, the guide rail 2 is a rectangular encircling structure with an upper opening, and the top has inner folds, and the cross section of the guide rail 2 is Type, the guide rail 2 has a rectangular guide cavity 9. The aforementioned guide rail 2 is stamped and formed by explosive welding of two layers of train guide rail steel plates and the aluminum alloy plate clamped between them. The train guide rail steel plate is made of medium carbon steel containing 0.6%wt of titanium and 0.2%wt of vanadium through hot rolling Molding, its specification depends on the design requirements. The two sides of the guide cavity 9 of the aforementioned guide rail 2 are respectively provided with guide rail-side guide poles 4 , and the bottom is provided with guide-rail side drive magnetic poles 6 .

[0024] The car body 1 is mainly composed of the car body 10 and the car ...

Embodiment 2

[0038] The present invention includes the matching car body and guide rail.

[0039] Among them, the guide rail is a rectangular encircling structure with an upper opening, and the top has inner folds, and the cross section of the guide rail is Type, with a rectangular guide cavity in the guide rail. The aforementioned guide rail is stamped and formed by explosive welding of two layers of train guide steel plates and the aluminum alloy plate clamped between them. The train guide rail steel plate is formed by hot rolling of medium carbon steel containing 0.3%wt of titanium and 0.4%wt of vanadium. , and its specification depends on the design requirements. Both sides of the guide cavity of the aforementioned guide rail are respectively provided with guide rail-side guide magnetic poles, and the bottom is provided with guide-rail side drive magnetic poles.

[0040] The car body is mainly composed of the car body and the car body support at the bottom of the car body. The car b...

Embodiment 3

[0054] The present invention includes the matching car body and guide rail.

[0055] Among them, the guide rail is a rectangular encircling structure with an upper opening, and the top has inner folds, and the cross section of the guide rail is Type, with a rectangular guide cavity in the guide rail. The aforementioned guide rail is stamped and formed by explosive welding of two layers of train guide steel plates and the aluminum alloy plate clamped between them. The train guide rail steel plate is formed by hot rolling of medium carbon steel containing 0.3%wt of titanium and 0.4%wt of vanadium. , and its specification depends on the design requirements. Both sides of the guide cavity of the aforementioned guide rail are respectively provided with guide rail-side guide magnetic poles, and the bottom is provided with guide-rail side drive magnetic poles.

[0056] The car body is mainly composed of the car body and the car body support at the bottom of the car body. The car b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single fiber diameter | aaaaa | aaaaa |

| Single fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com