Processing method of a multi-degree-of-freedom piezoelectric driven flapping-wing micro air vehicle and a transmission mechanism thereof

A technology of piezoelectric drive and flapping wing aircraft, which is applied in the field of micro flapping wing aircraft and micromachining, can solve the problems of imperfection, immature processing conditions, and no flapping wing aircraft, etc., and achieve small size, light weight, and excellent balance Effects on sex and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

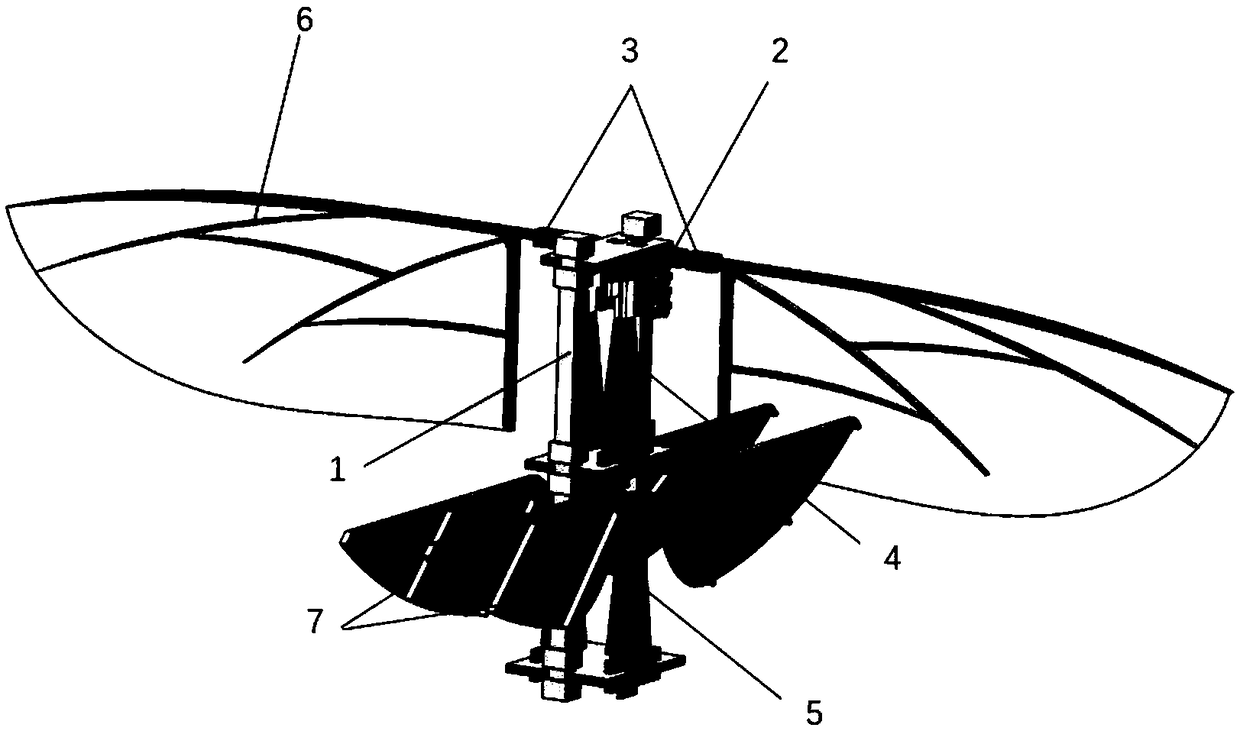

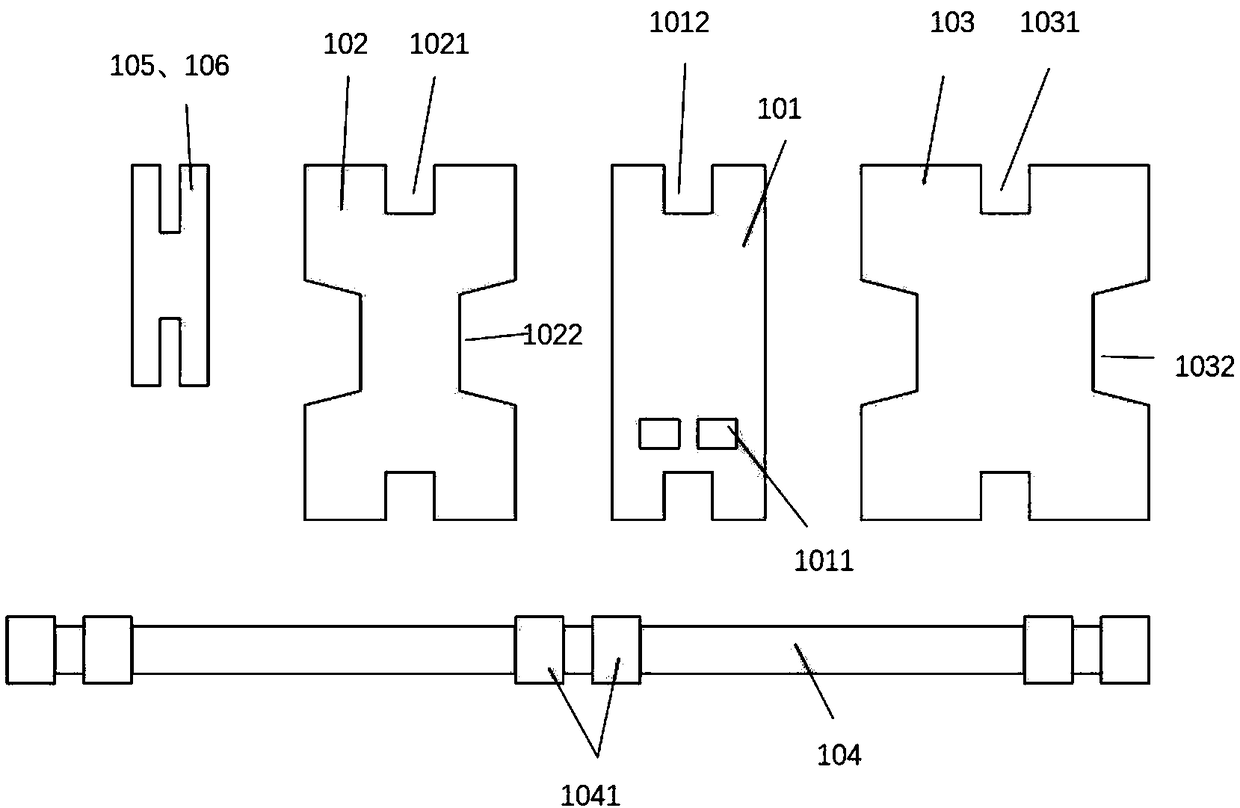

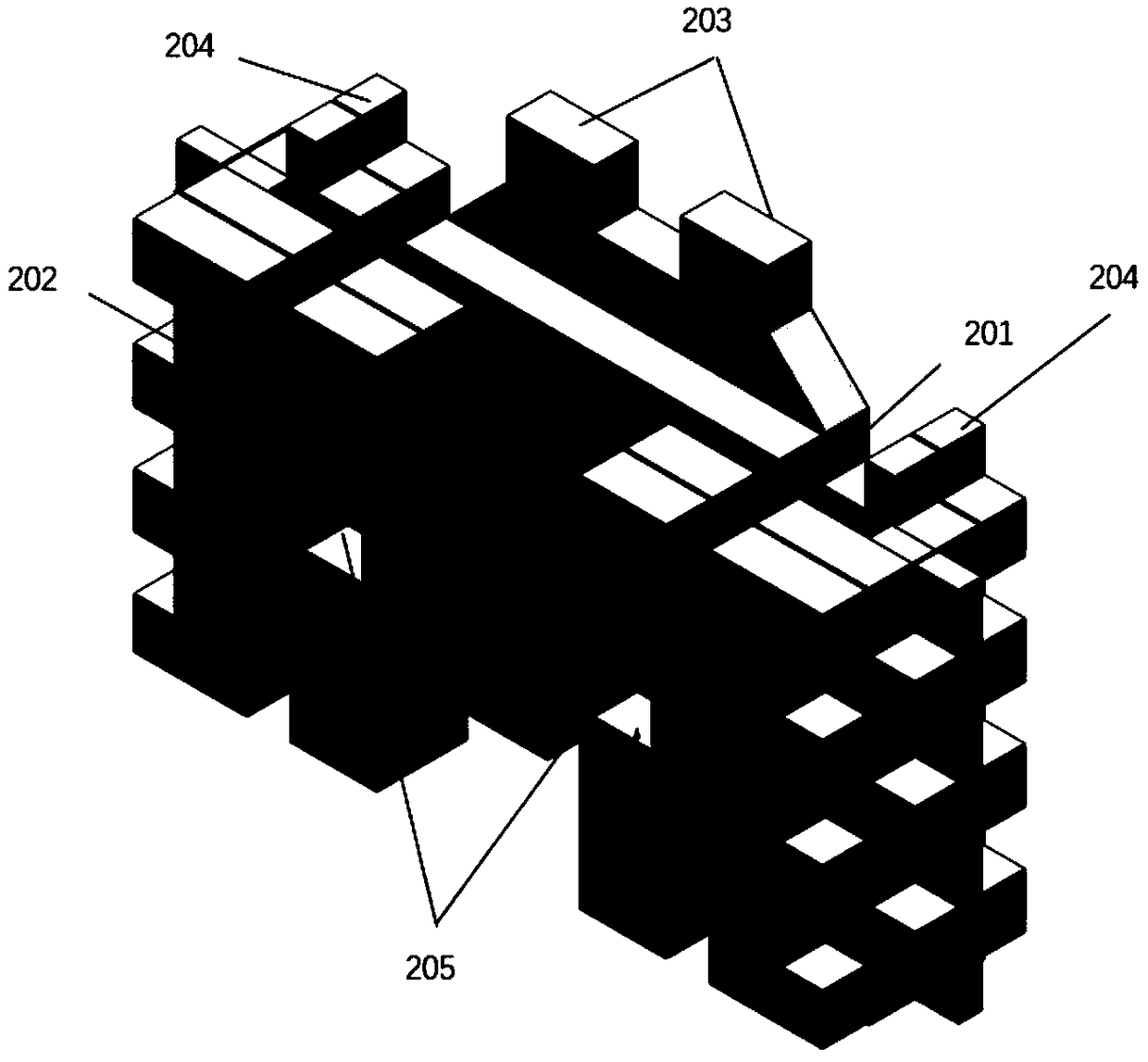

[0035] Such as figure 1 As shown, a multi-degree-of-freedom piezoelectric-driven miniature flapping-wing aircraft includes an aircraft fuselage 1, a transmission mechanism 2, two flexible hinges 3, a pair of first bimorph piezoelectric actuators 4, a pair of second bimorph Chip piezoelectric driver 5, a pair of main wings 6 and two pairs of auxiliary wings 7, the fuselage of the aircraft is penetrated by two columns; the transmission mechanism is fixed on the top of the aircraft fuselage; The auxiliary wings are respectively attached to the two sides of a pair of second bimorph piezoelectric actuators; a pair of main wings are respectively attached to the flexible hinges on the left and right sides above; The movable part is connected with the transmission mechanism, and the lower end is fixed on the fuselage of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com