Vacuum forming packaging machine for strip-shaped packaging bags

A vacuum forming and packaging bag technology, applied in packaging, pressurized/gasified packaging, etc., can solve the problems of packaging bag wrinkles, air leakage, residual air, etc., and achieve the effect of preventing poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

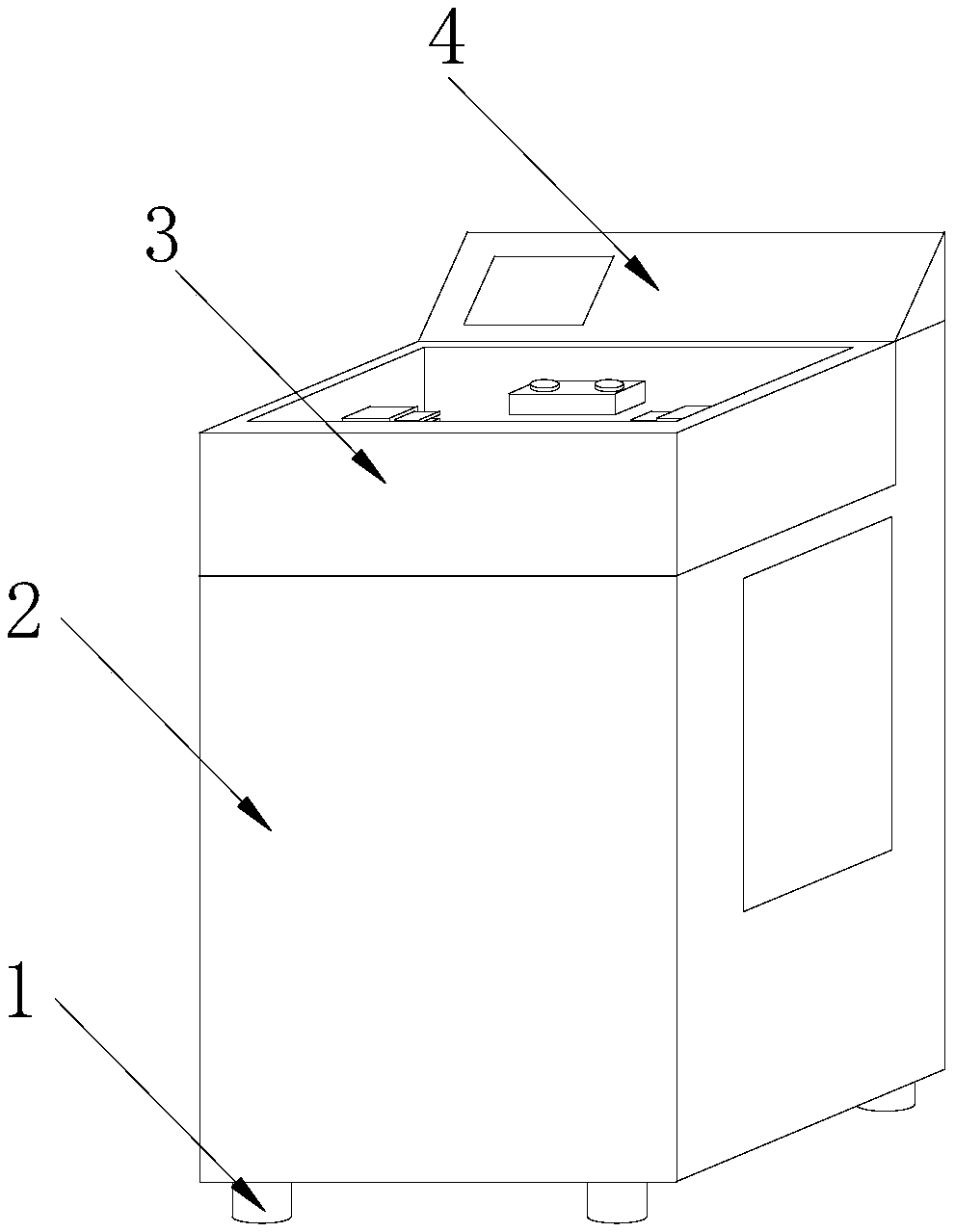

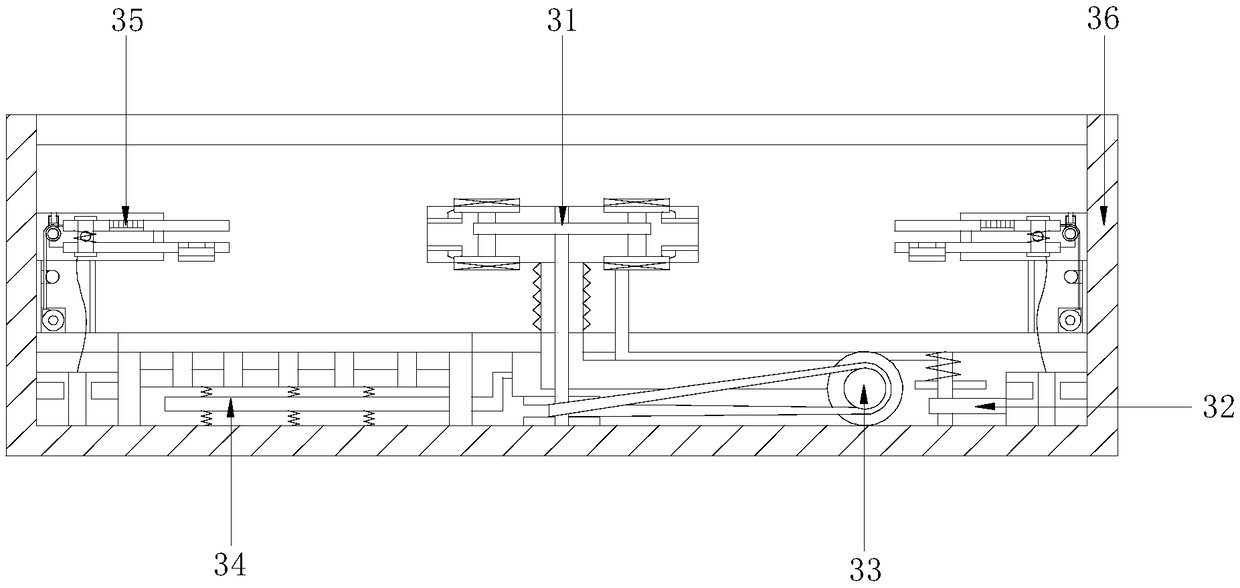

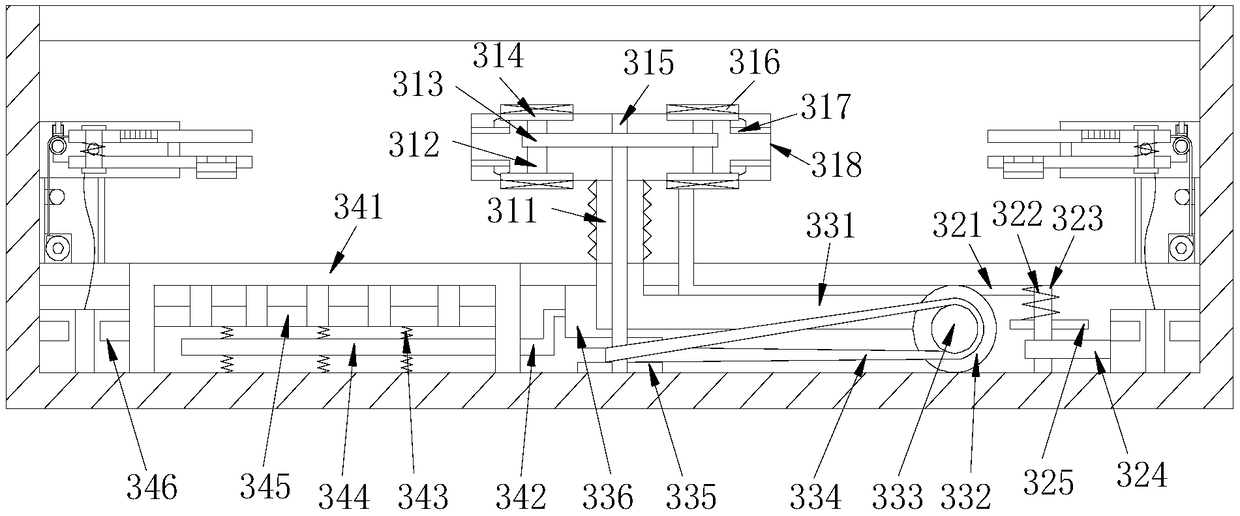

[0029] see Figure 1-Figure 9, the present invention provides a vacuum forming packaging machine for strip packaging bags, the structure of which includes a base 1, a body 2, a pleat-removing and leak-proof device 3, and an operation panel 4. On the lower surface of the body 2, the anti-crease and leak-proof device 3 is horizontally installed on the upper surface of the body 2, the operating panel 4 is horizontally installed on the upper surface of the body 2, and the feet 1 are installed on the pleat removal through the body 2. The lower position of the leak-proof device 3, the operation panel 4 is installed behind the pleat-removing leak-proof device 3, and the pleat-removing leak-proof device 3 includes a burr treatment mechanism 31, a conduction mechanism 32, a transmission mechanism 33, and a static elimination mechanism 34 , a wrinkle processing mechanism 35 , and a housing 36 .

[0030] The burr processing mechanism 31 is horizontally installed in the middle position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com