Cutting device for packing bag

A cutting device and packaging bag technology, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of repeated and cumbersome operation processes, and achieve the effects of simple and convenient operation, labor saving, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the technical solution disclosed in the present invention in detail, further elaboration will be made below in conjunction with the accompanying drawings and specific embodiments.

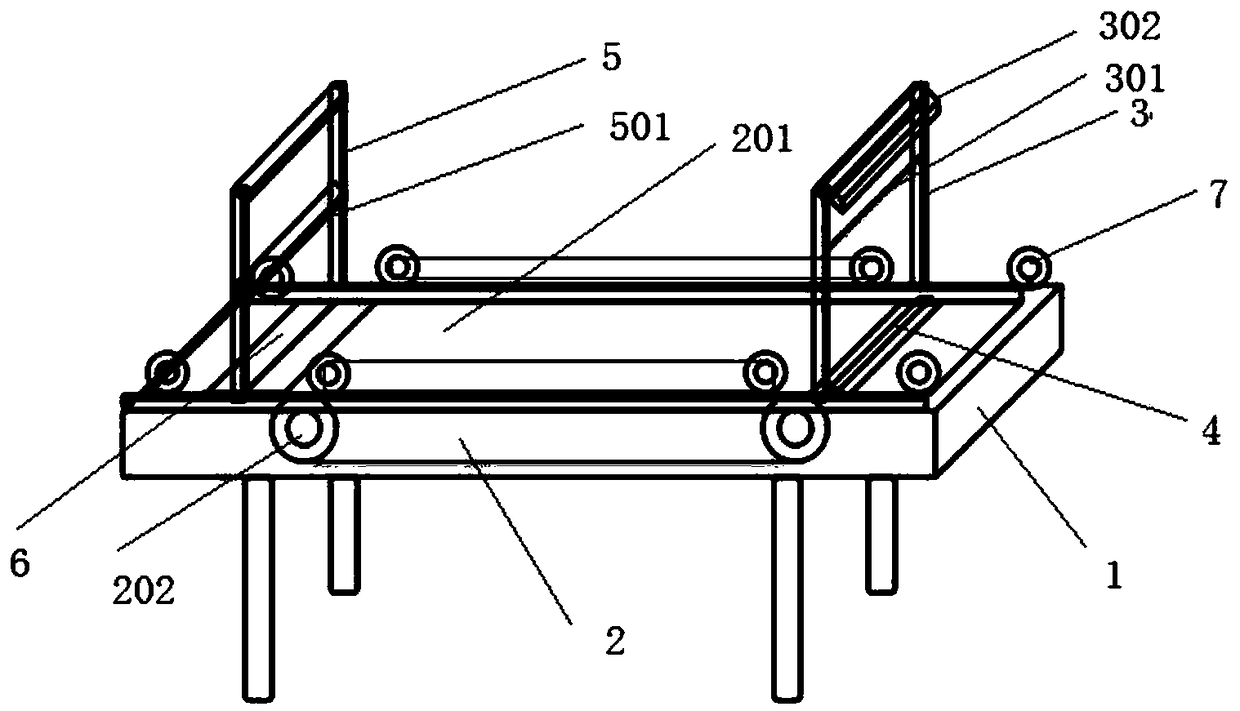

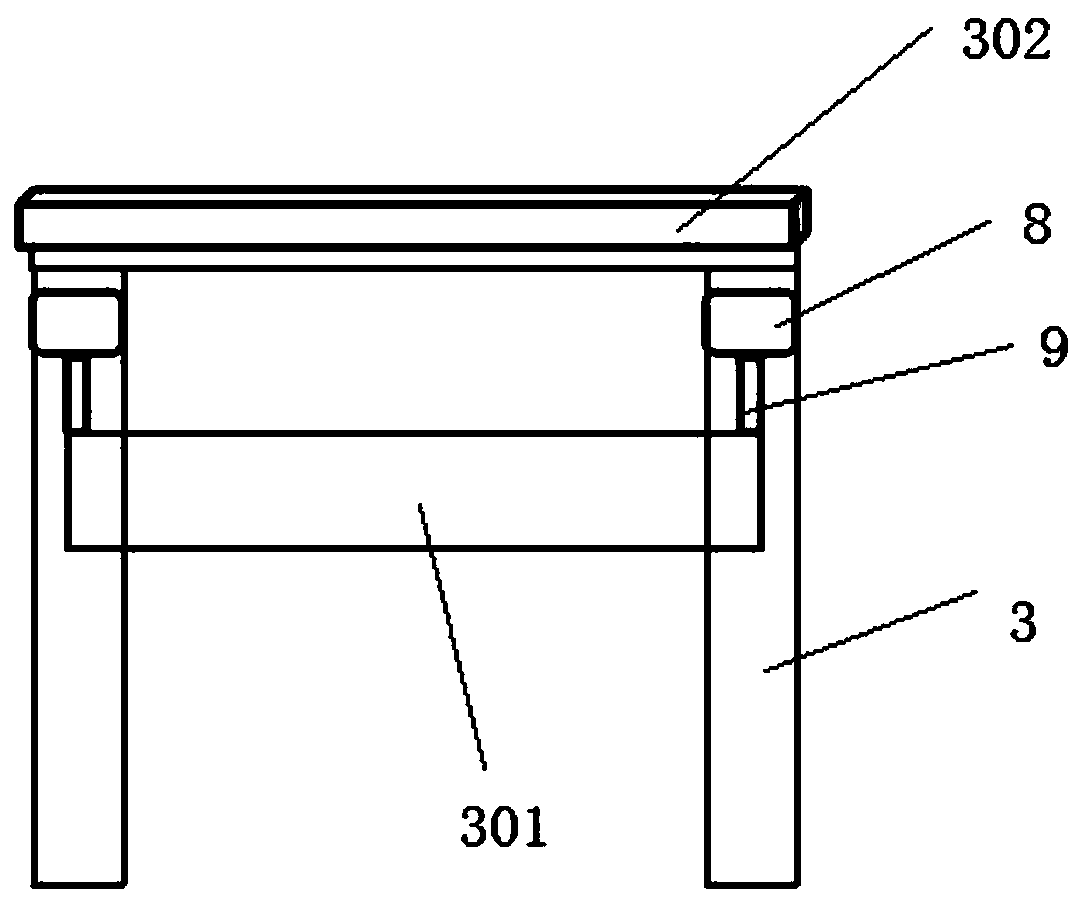

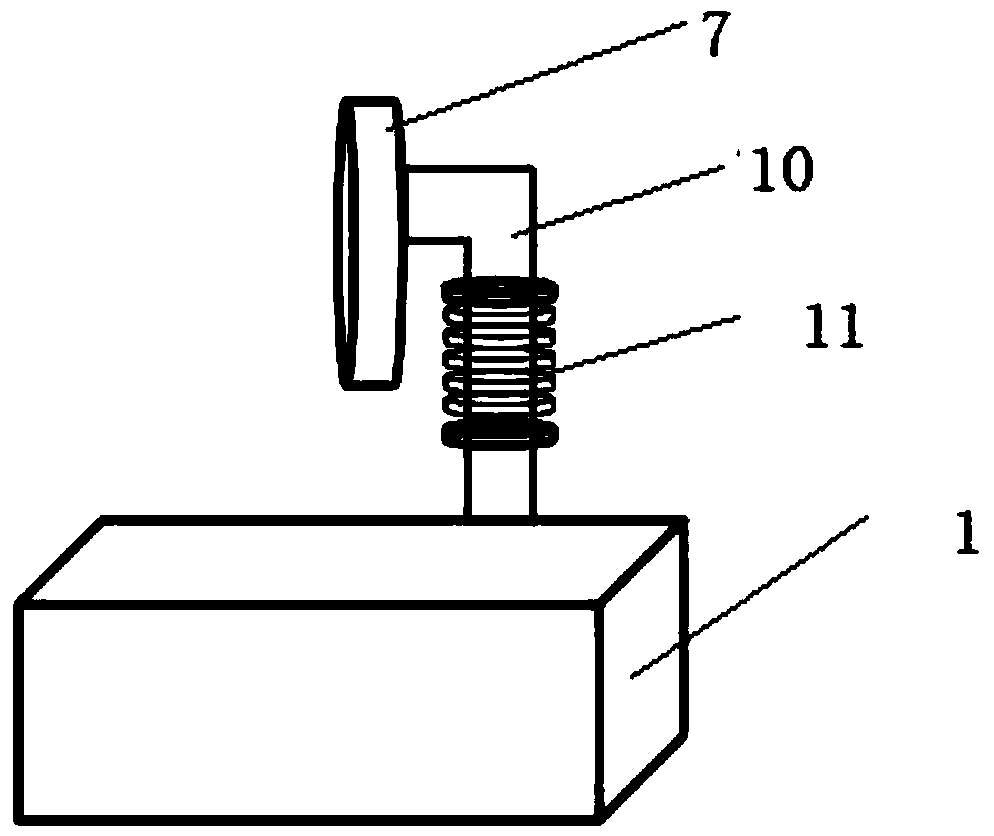

[0016] The invention discloses a packaging bag cutting device, the structure of which is as follows: figure 1 shown. The device includes a frame 1, a transmission platform 2, a cutting device 3, a cutting notch 4, a heat sealing device 5, a heating pad 6 and an extrusion wheel 7. The middle part of the frame 1 is embedded with a transmission platform 2, and the transmission platform 2 Cutting device 3 and heat sealing device 5 are respectively installed on both sides of the frame 1, cutting notch 4 and heating backing plate 6 are respectively provided directly below the cutting device 3 and heat sealing device 5, and the two sides and surroundings of frame 1 are also provided with Squeeze wheel 7, the metal film or plastic film that makes packaging bag passes through cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com