Glass fiber felt rapid continuous production system

A technology of glass fiber felt and production system, which is applied in the direction of tool storage devices, types of packaging items, special packaging items, etc. It can solve the problems of uneven spraying of adhesives, slow manual replacement speed, and large investment of human resources, etc., and achieves improvement. Work efficiency, reduce manpower input, and evenly spread the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation of the present invention will be further described below in conjunction with the examples.

[0057] In the following embodiments, the first and second fixing seats each have three fixing seats as an example, that is, the fixing seat A, the fixing seat B, the fixing seat C, the fixing seat a, the fixing seat b, and the fixing seat c have the same structure , the first reel, the second reel, and the third reel have the same structure, where the first, second, A, B, C, a, b, c are only used for identification of relative positional relationship, and are not used to limit the feature itself, In addition, hereinafter, the reel is an air shaft and a paper tube is sleeved on the air shaft, so that the rolled glass fiber mat roll and the air shaft can be better separated.

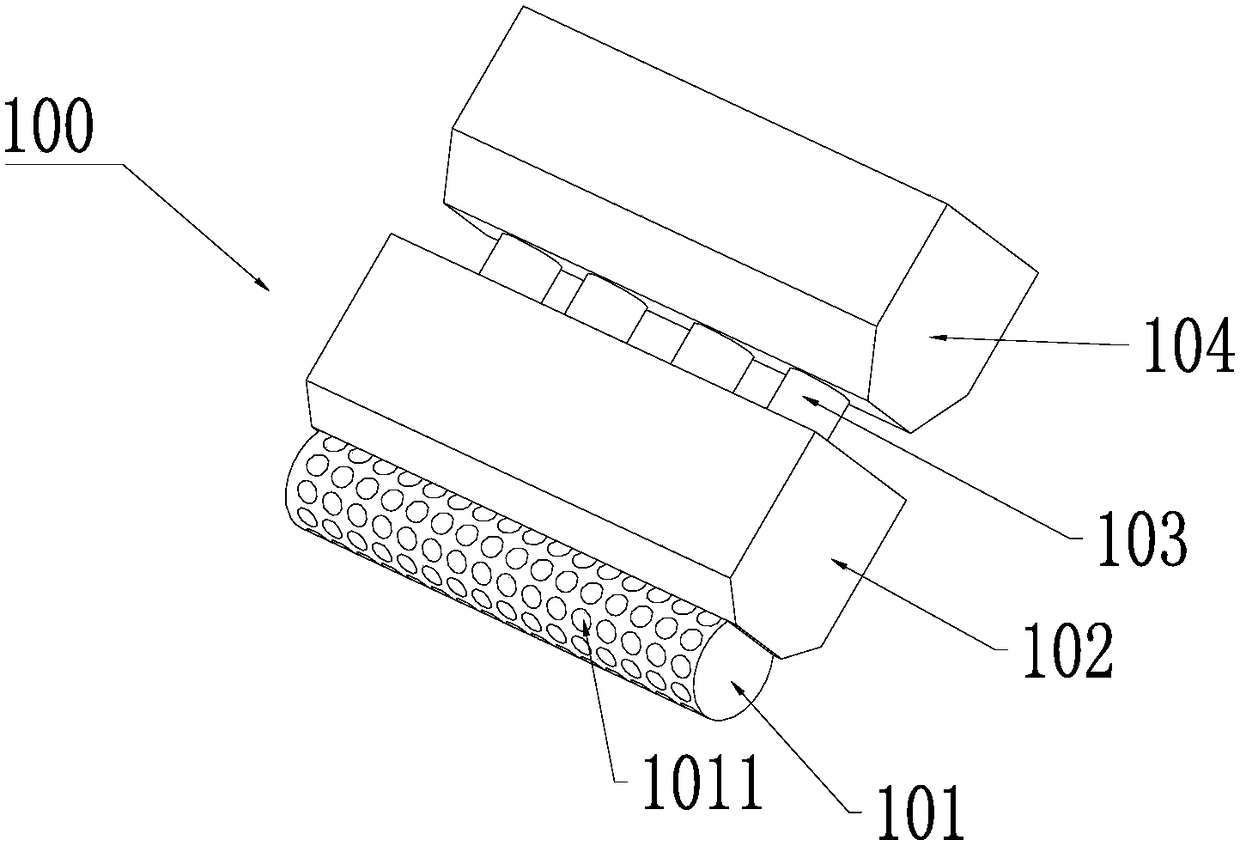

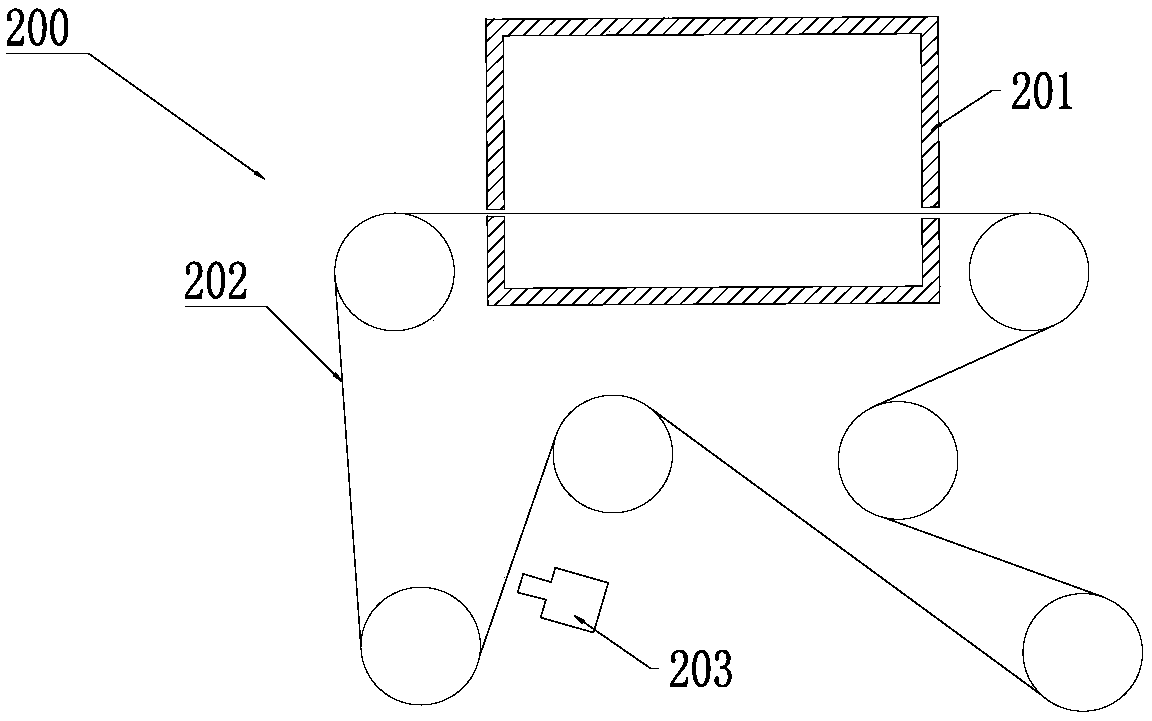

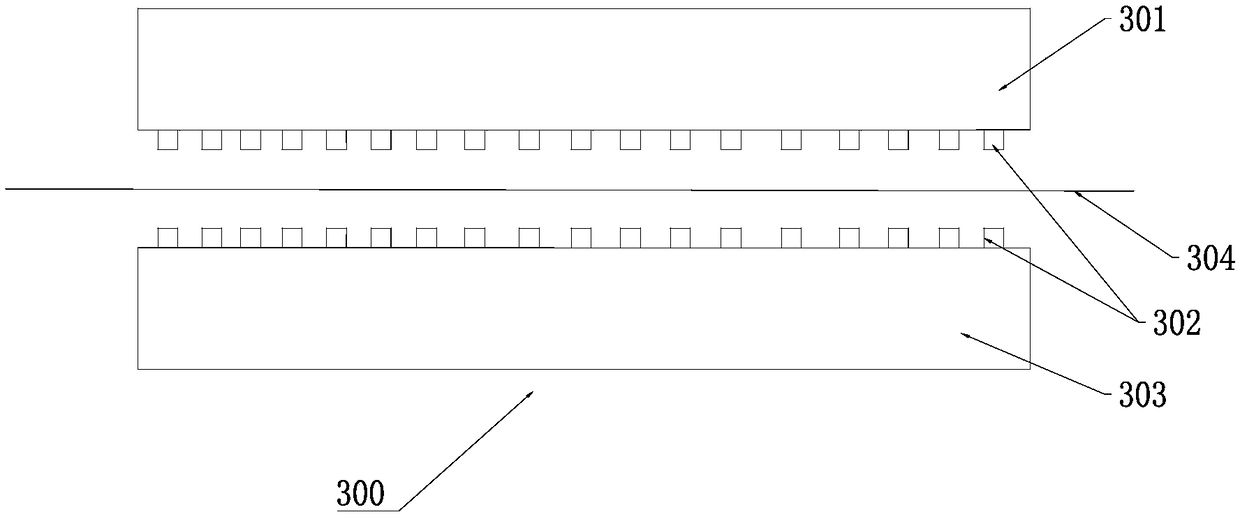

[0058] Such as Figure 1-11 As shown, the rapid and continuous production system of glass fiber felt, the production system includes a cutting device for glass fiber yarn cluster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com