Winding machine winding head structure for processing of polyester filament products

A technology of polyester filament and winding machine, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. The problem of wire damage and other problems is achieved, and the winding forming is stable and reliable, the work efficiency is improved, and the winding forming is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

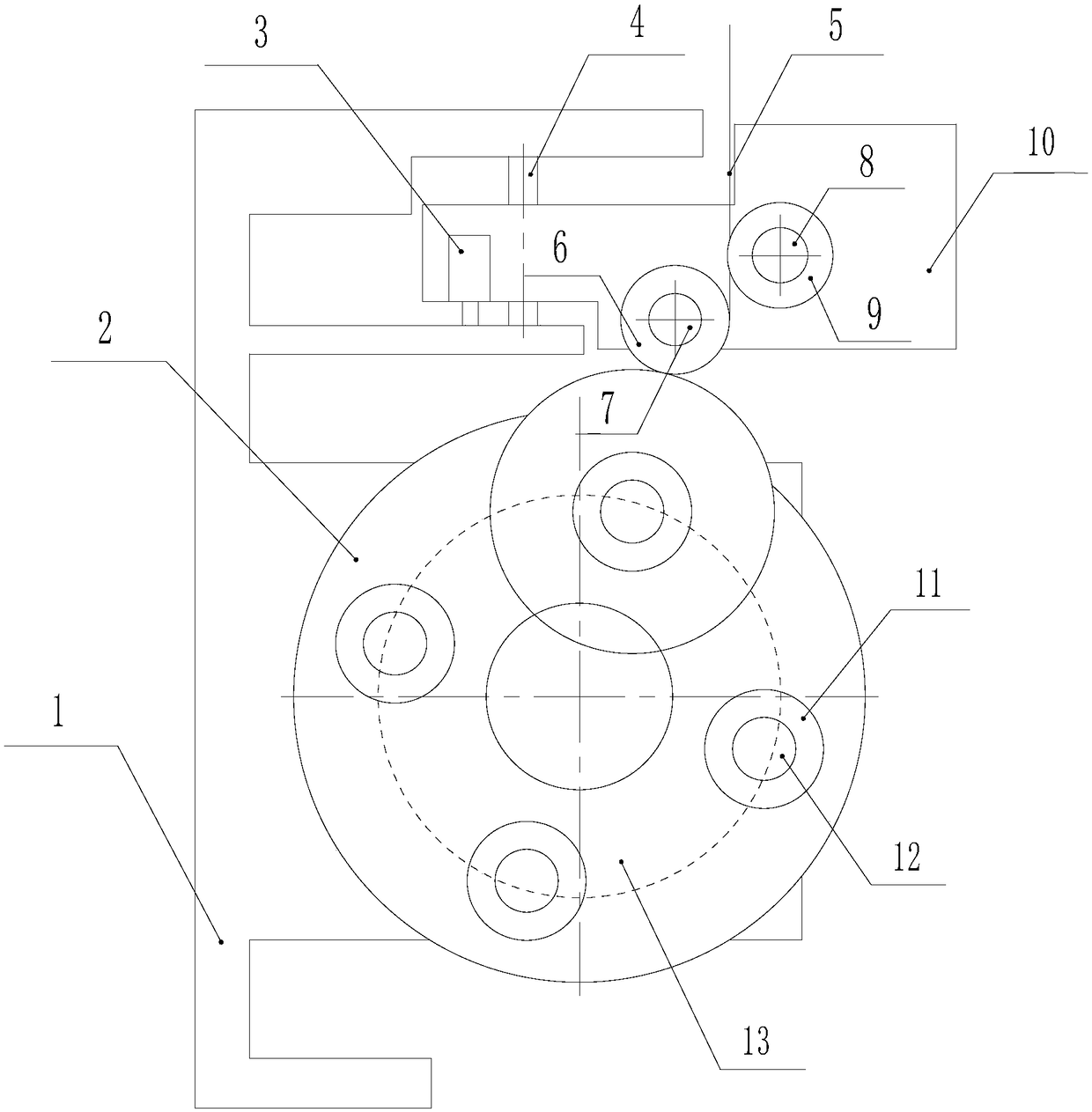

[0015] A winding head structure of a winding machine for processing polyester filament products, which includes a frame 1, a turntable 2, a cylinder 3, a guide column 4, spinning 5, a friction roller 6, a driving motor 7, a first pillar 8, Grooved roller 9, housing 10, chuck 11, second pillar 12 and indexing motor 13, described indexing motor 13 is fixedly installed on the frame 1, and described turntable 2 is installed on the output of indexing motor 13 On the shaft, four second pillars 12 are evenly distributed along the circumferential direction on the front end surface of the turntable 2, bearings are installed on the second pillars 12, and the chuck 11 is installed on the bearings. The driving motor 7 is installed on the housing 10, the friction roller 6 is installed on the output shaft of the driving motor 7 and the friction roller 6 is pressed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com