Rotating joint of rubber tube of oiling machine

A technology of rotary joint and fuel dispenser, which is used in liquid distribution, conveying or transfer devices, special distribution devices, packaging, etc., can solve the problems of high labor intensity, unfavorable sealing, scratching vehicles, etc., to reduce labor intensity and prevent leakage. Oil, the effect of avoiding seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

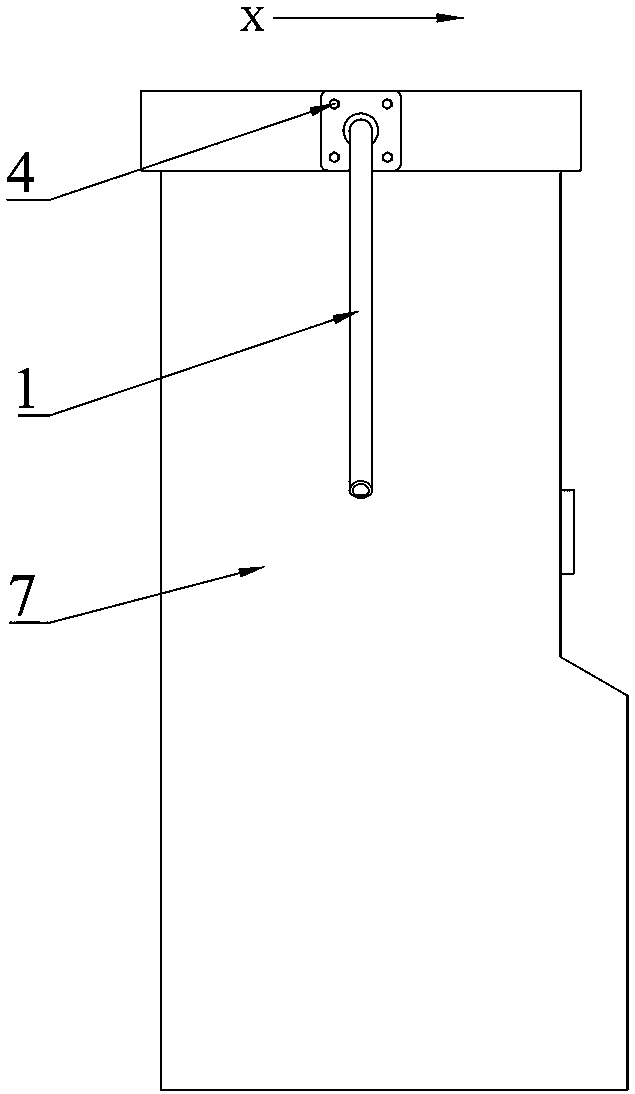

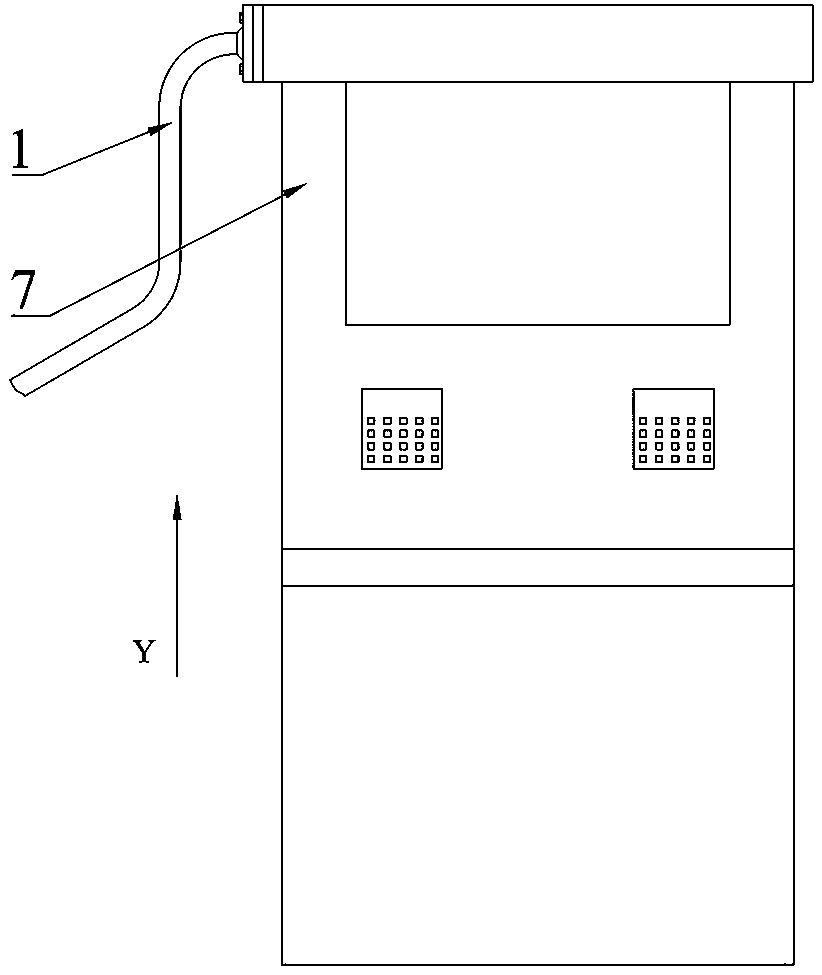

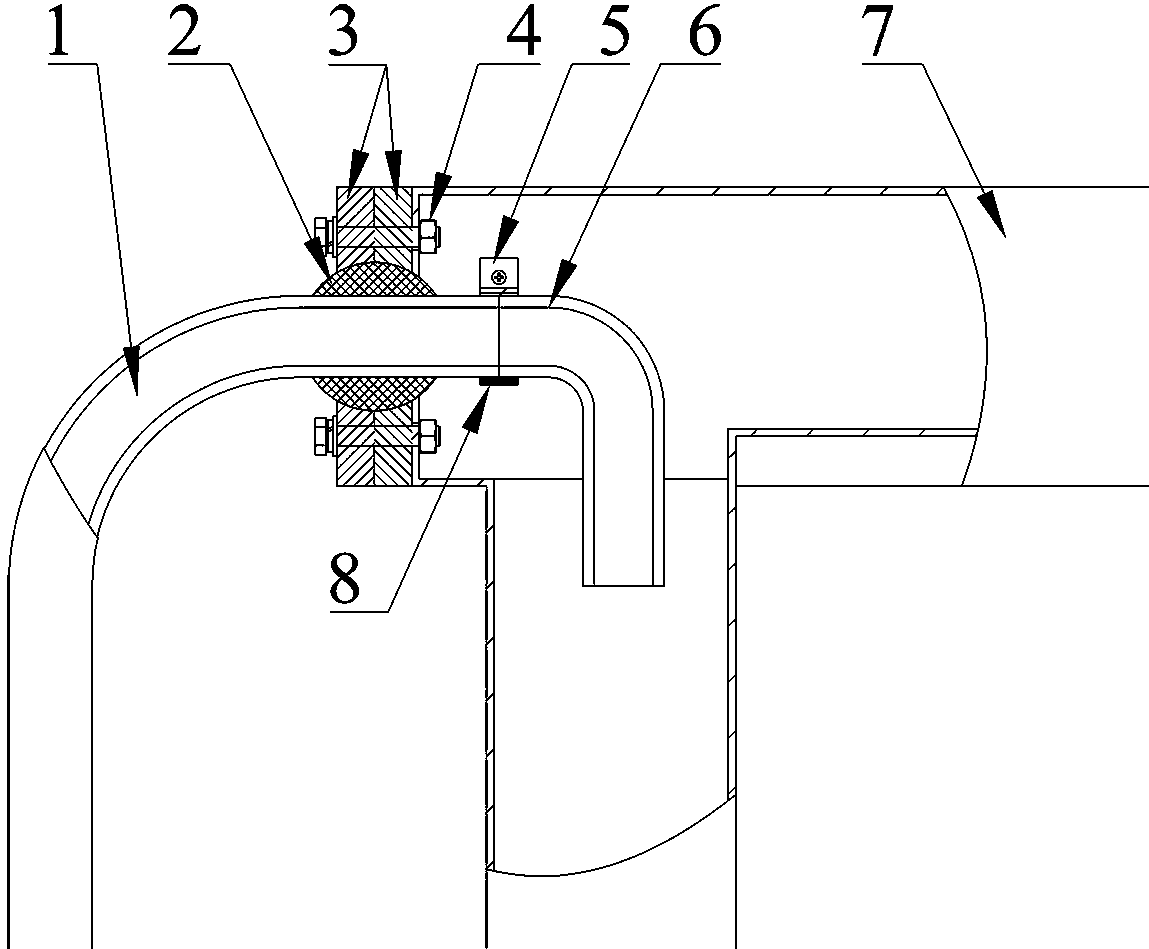

[0031] A fuel dispenser rubber hose rotary joint, the structure of which is as follows Figure 1~3 As shown, it includes an oil gun rubber hose 1 and a joint body fixedly connected to the fuel dispenser 7 . The joint body includes a spherical joint 2. The spherical joint 2 is a spherical structure with a cylindrical through hole on the central axis. The spherical joint 2 is symmetrically provided with two joint sleeves 3 with arc-shaped chambers along the vertical plane. The structures of the joint sleeves 3 are exactly the same. The arc chambers of the two joint sleeves 3 cooperate to form the accommodation cavity of the spherical joint 2. The outer surface of the spherical joint 2 is rotatably matched with the inner surface of the accommodation cavity. The spherical joint 2 is pinched from two directions and tightly merged. The accommodation cavity formed after the two joint sleeves 3 are tightly merged is in contact with the outer surface of the spherical joint 2 but does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com