A Method for Improving the Corrosion Resistance of Tellurium of UNS N10003 Alloy

A technology for corrosion properties and alloys, which is applied in the field of improving the tellurium corrosion resistance of UNSN10003 alloys, can solve the problems of not being able to meet the corrosion resistance properties at the same time, deteriorate the molten salt corrosion resistance, and increase the cost of fuel salts, so as to improve the tellurium corrosion resistance, The effect of improving tellurium corrosion resistance and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

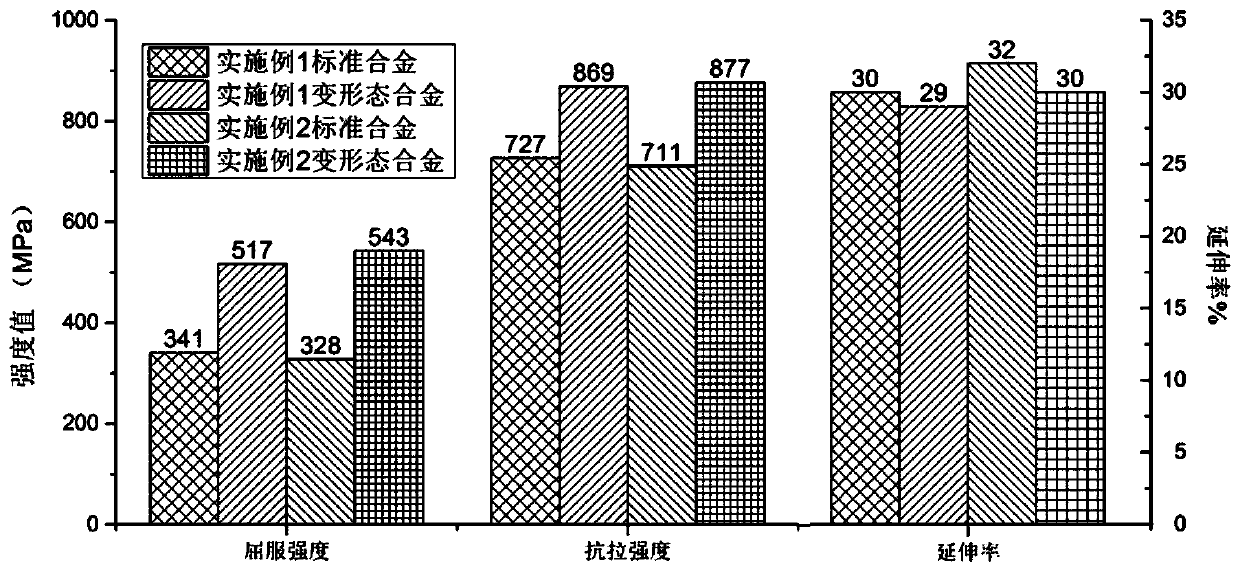

Embodiment 1

[0026] Example 1: Verification of tellurium corrosion resistance of hot-rolled UNS N10003 alloy rods.

[0027] The chemical composition of the hot-rolled UNS N10003 alloy bar in this example is shown in Table 1.

[0028] Table 1, UNS N10003 alloy composition (wt.%)

[0029] Ni Mo Cr Fe mn Si Example 1 Bal. 16.10 6.91 4.03 0.531 0.319 Example 2 Bal. 16.11 6.88 4.01 0.530 0.0562 C co Cu W Ti Al Example 1 0.0483 0.0293 0.0036 0.0458 0.0054 0.0708 Example 2 0.0572 0.0293 0.0037 0.0462 0.0054 0.0794

[0030] The alloy is melted and cast into a Φ508mm ingot through vacuum induction melting and vacuum self-consumption melting, and then homogenized and annealed at 1180°C for 2.5h, and then hot rolled into a Φ16mm bar.

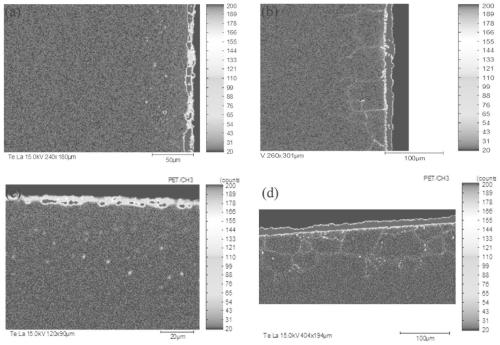

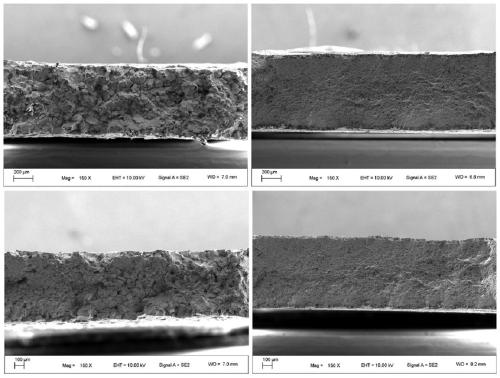

[0031] Tellurium and hot-rolled UNS N10003 alloy bar samples (without solution heat treatment) and standard UNS N10003 alloy samples (with solution heat treatment) were sealed in a va...

Embodiment 2

[0035] Example 2: Verification of tellurium corrosion resistance of standard solid solution state UNS N10003 alloy plate after hot rolling.

[0036] Put the 10mm thick standard solid solution state UNS N10003 alloy plate (see Table 1 for composition) into 1200℃ for 0.5h, take it out and roll it into a 6mm thick plate, put it in 1200℃ again for 0.5h, take it out and roll it into a 3mm thick plate Hot-rolled deformed sheet.

[0037] Tellurium and hot-rolled UNS N10003 alloy plate samples and standard UNS N10003 alloy samples were sealed in a vacuumed quartz tube to eliminate the influence of oxygen on the tellurium element and alloy samples. In order to ensure the vacuum effect in the quartz tube, the quartz tube containing the sample is washed with high-purity argon gas (99.999% pure) after vacuuming to ensure that the oxygen content in the quartz tube reaches the minimum, and then the vacuum is used. Sealing equipment-quartz glass tube rotary sealing machine seals the quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com